Method for changing solid film material surface soakage

A film material and surface infiltration technology, which is used in the field of changing the surface wettability of solid film materials by needle type printers, can solve the problems of expensive equipment, radioactive pollution, complicated operation process, etc., and achieve large-scale rapid preparation, easy operation, and equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

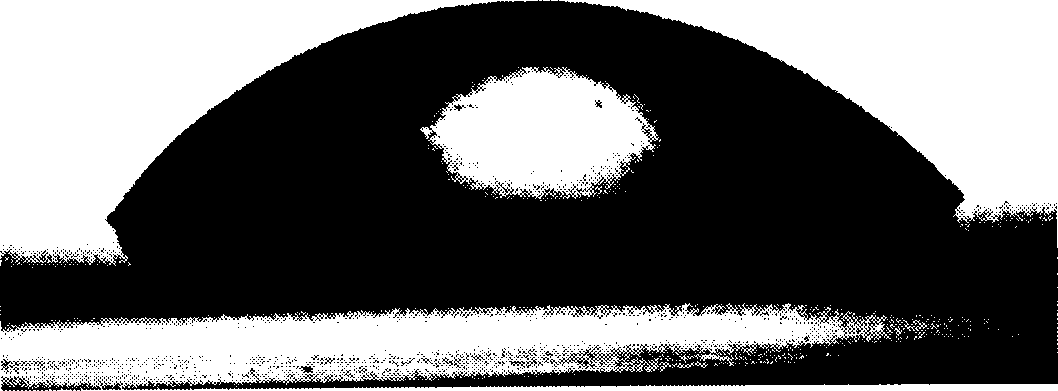

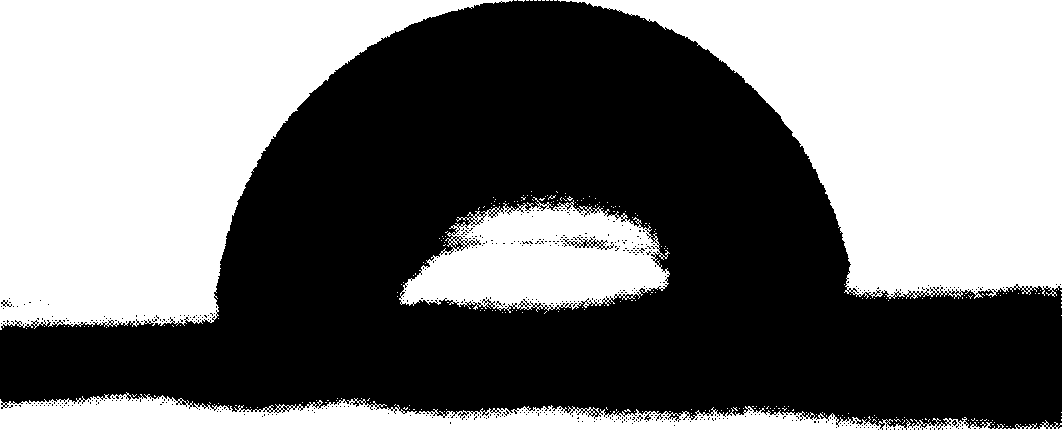

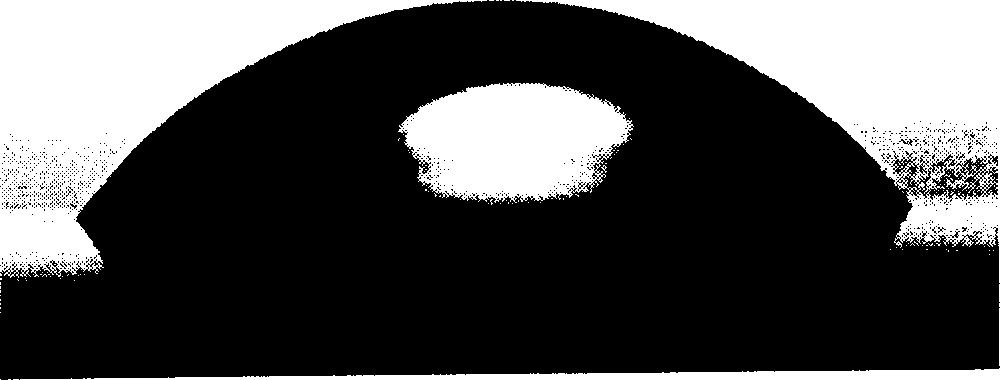

[0037] When the dot matrix printer used is Epson LQ300K+, at room temperature, use laser etching to modify the micron structure on the surface of the printing needle, the groove size is 6-7 microns, and print on the surface of 0.2mm thick aluminum foil. The contact angle of the aluminum foil surface changed from 49.6° to 68.8°.

Embodiment 2

[0039] When the stylus printer used is Epson LQ300K+, at room temperature, use laser etching to modify the surface of the printing needle with a micron structure, the groove size is 3-5 microns, and print on the surface of 0.02mm thick tin foil. The surface contact angle of tin foil changed from 41.6° to 96.2°.

Embodiment 3

[0041] When the stylus printer used is Epson LQ300K+, at room temperature, use laser etching to modify the surface of the printing needle with micron and nanostructures, the aperture size is 0.1-2 microns, and print on the surface of 0.02mm thick copper foil. The contact angle of copper foil surface changed from 45.4° to 61.8°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com