A protective coating with high hardness and hydrophobic properties, its preparation method and application

A protective coating and hydrophobic technology, which is applied in the coating, metal material coating process, vacuum evaporation plating, etc., can solve the problem of deterioration of the mechanical properties of the film, and achieve the effects of enhanced mechanical properties, simple preparation process, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Substrate pretreatment: Before the single crystal Si(100) substrate is loaded into the sputtering chamber, it needs to be pretreated. Use acetone, absolute ethanol and deionized water to clean it sequentially for 15 minutes, and blow it with nitrogen. Dry;

[0019] (2) Target installation and vacuuming: install the substrate obtained by the above cleaning on the sample stage, and install the Ta target and the Cu target on the target stage respectively, close the vacuum chamber, and turn on the mechanical pump and the molecular pump to vacuumize successively , the vacuum degree needs to reach 8×10 -4 Below Pa;

[0020] (3) Pre-sputtering: before the start of sputtering, in order to remove the impurity atoms adsorbed on the target, such as oxygen on the Ta target, copper oxide on the surface of the Cu target, etc., pure argon gas is introduced to pre-sputter the target. Sputtering for 15 minutes, and then depositing a pure metal Ta coating on the substrate Si as a t...

Embodiment 2

[0025] With embodiment 1, the sputtering parameter in step 4 is:

[0026] High-purity Ta and Cu are used as target sources, where Ta target is connected to DC power supply, Cu target is connected to RF power supply, Ar and N 2 As discharge gas, deposit TaCuN film on single crystal silicon substrate, where the power of Ta target is 200W, the power of Cu target is 5W (the power ratio of Cu and Ta is 2.5:100), and the total sputtering pressure is 0.8Pa , Ar and N 2 The flow rate ratio is 2.2~1, the deposition temperature is controlled at room temperature, the target base distance is 80mm, and the vacuum degree is 8×10 -4Pa, the voltage applied to the substrate is -200V.

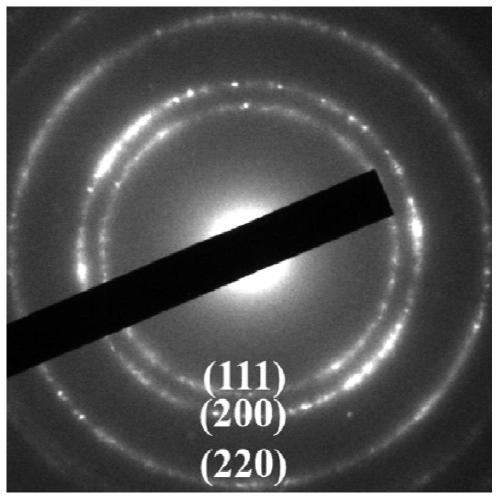

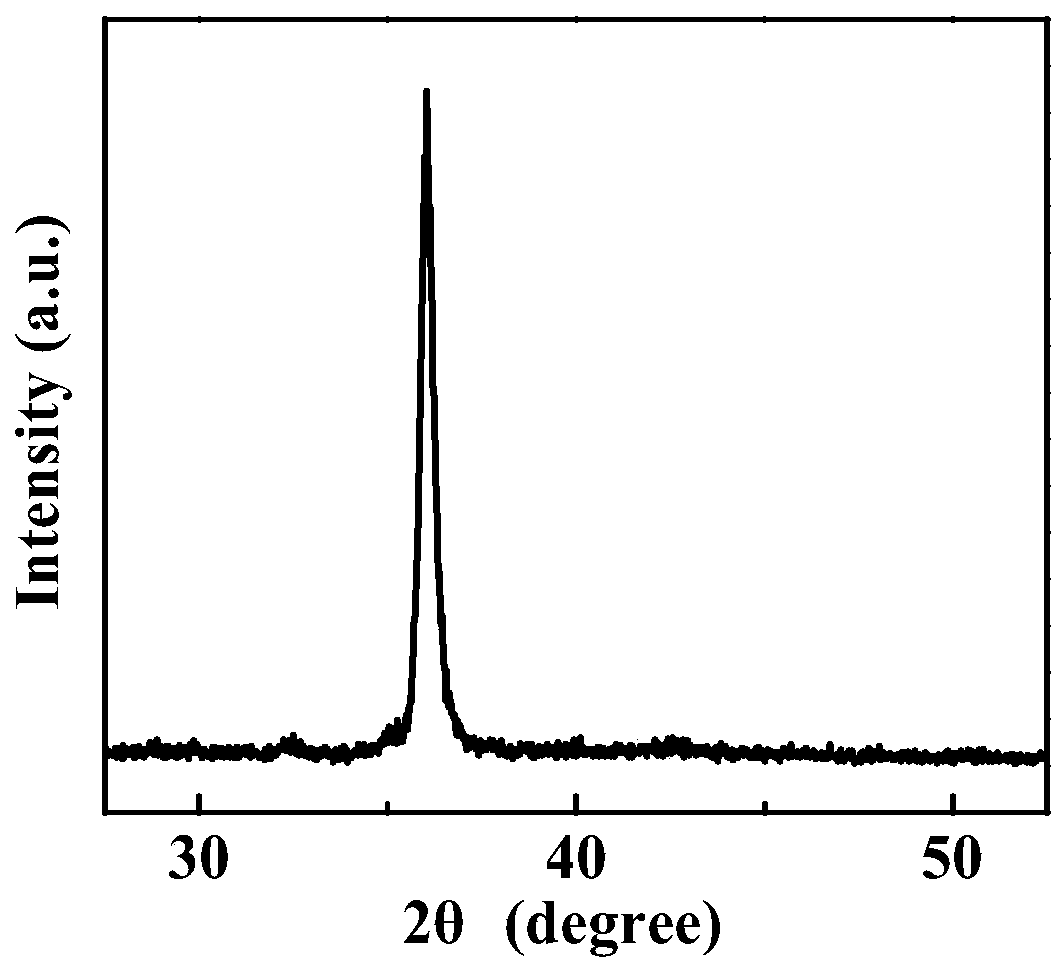

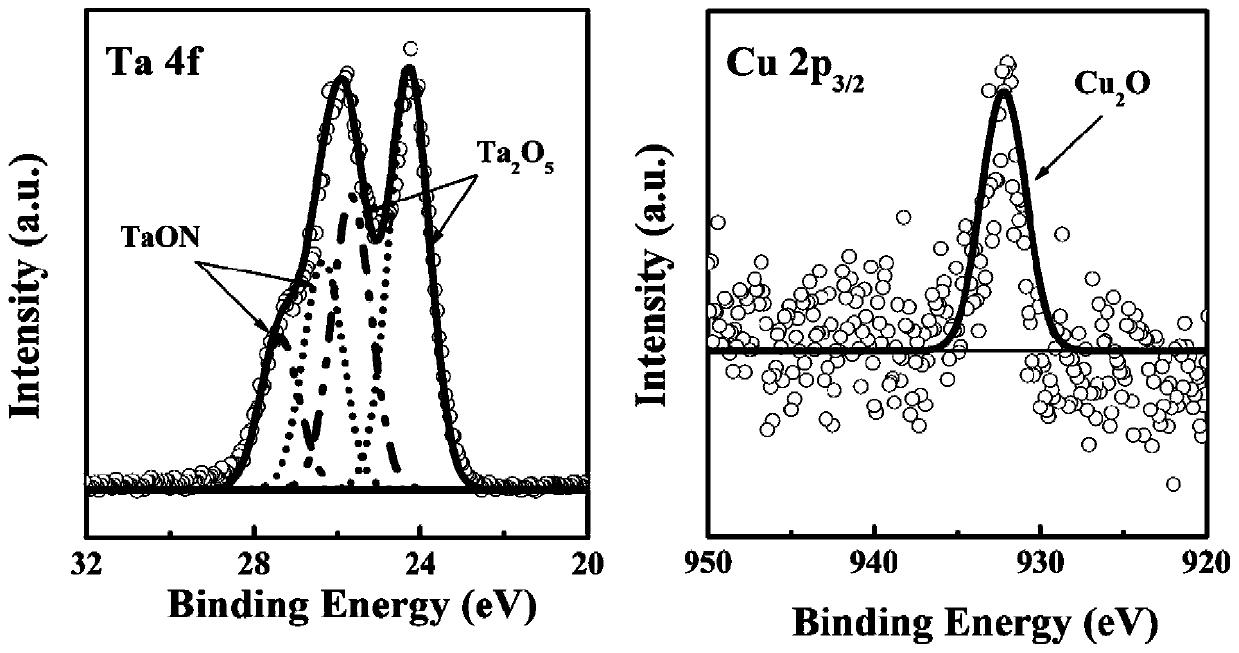

[0027] The TaCuN thin film obtained under this condition has a Ta content of 49.6%, a N content of 48.5%, and a copper content of 1.9%. It was proved by XRD and selected electron diffraction that the TaCuN thin film structure obtained at this time is a TaCuN replacement solid solution with a cubic structure a...

Embodiment 3

[0029] With embodiment 1, the sputtering parameter in step 4 is:

[0030] Using the co-sputtering method, high-purity Ta and Cu are used as target sources, where the Ta target is connected to a DC power supply, the Cu target is connected to a radio frequency power supply, Ar and N 2 As discharge gas, deposit TaCuN film on single crystal silicon substrate, where the power of Ta target is 200W, the power of Cu target is 12W (the power ratio of Cu and Ta is 6:100), and the total sputtering pressure is 0.7Pa , the deposition temperature is controlled at room temperature, the target base distance is 80mm, and the vacuum degree is 8×10 -4 Pa, Ar and N 2 The flow rate ratio is 2.0-1, and the voltage applied on the substrate is -100V;

[0031] The TaN film obtained under this condition has a Ta content of 41.3%, a N content of 49.1%, and a copper content of 7.8%. It was proved by XRD and selected electron diffraction that the TaCuN thin film structure obtained at this time is a TaC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com