Damper throttle for insulating smoke

A technology that isolates baffles and dampers. It is applied to engine components, mechanical equipment, valve devices, etc. It can solve the problems of easy entry of smoke and dust impurities into the sealing cavity, increased error probability, and complex structure. The effect of reducing the leakage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

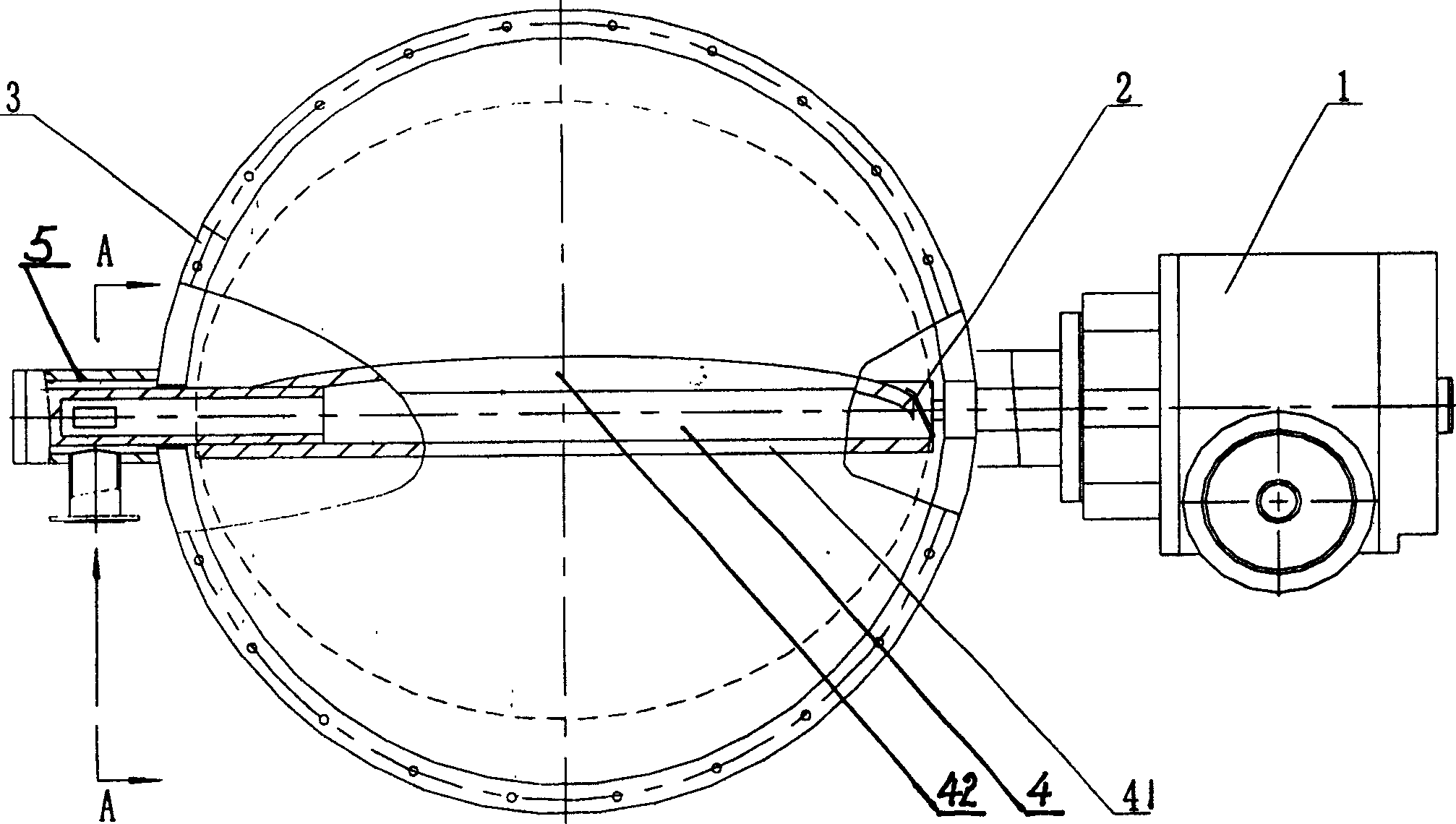

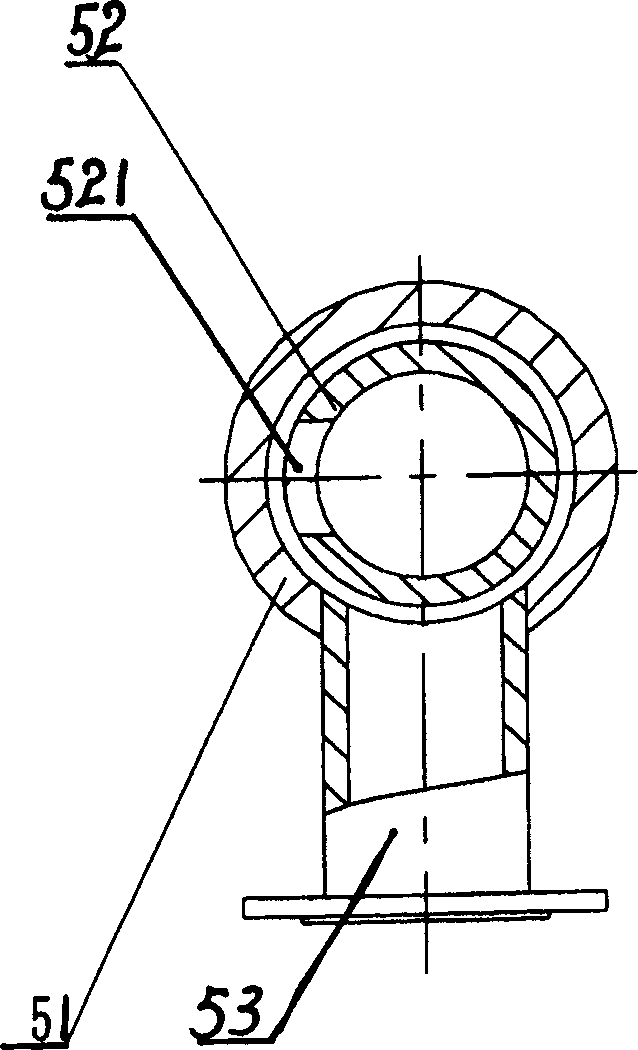

[0015] Examples of the present invention are figure 1 , the actuator 1 is driven by a prime mover such as an electric motor or a cylinder, which is a commercially available stereotyped product. The sealing sheet 2 is made of elastic materials such as 316LMN stainless steel, C276 nickel-based alloy and other materials. The valve body 3 and the switching valve stator part 51 are integrally manufactured. The fixed valve plate 41, the movable valve plate 42, and the switching valve rotor part 52 are constructed of steel pipes.

[0016] Structurally, the present invention is composed of a windshield, a casing and a control device. The smoke isolation baffle damper includes a valve body 3 with a self-closing structure valve plate with a closed cavity, an intermediate medium control switching valve 5, and an electric actuator 1. ; wherein the electric actuato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com