Guanido vitriol compound and its extraction and separation method

A separation method and compound technology are applied in the field of compounds to achieve the effects of small molecular weight, simple and feasible method and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

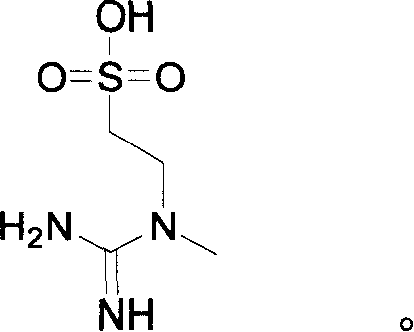

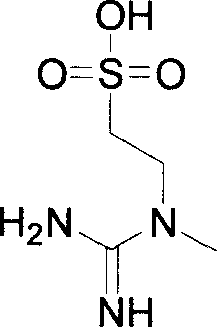

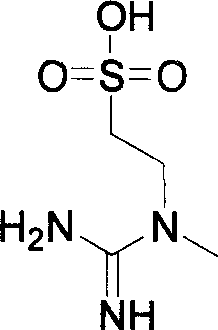

[0016] A kind of guanidine sulfuric acid compound structural formula is as follows:

[0017]

[0018] Its extraction and separation method uses the wrinkled soft sponge (Halichondria rugosa Ridley&Dendy) from the South China Sea as a raw material, and adopts the method of combining a normal-phase column and a reverse-phase column, which can be operated as follows:

[0019] The wrinkled soft sponge (Halichondria rugosa Ridley&Dendy) from the South China Sea was collected, stored in a -20°C refrigerator immediately after collection, freeze-dried (100 g) before use, crushed, mechanically stirred in methanol for extraction, and repeated 4 times. The extracts were combined and reduced. Concentrate to a slurry by pressure distillation, disperse the slurry evenly in 100ml of water, and extract three times successively with an equal amount of cyclohexane, ethyl acetate, and n-butanol respectively, and concentrate the n-butanol extract under reduced pressure. The product was eluted ...

Embodiment 2

[0025] 2 kg of the collected fresh sponge was minced, directly stirred and extracted with 2000 ml of methanol, the extract was concentrated to 1000 ml, and then extracted and separated sequentially in the same manner as in Example 1 to obtain colorless needle-like crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com