Method for synthesizing sec-butyl urea

A technology of sec-butylurea and sec-butylamine, applied in the field of compound synthesis, can solve the problems of poor safety, inconvenient operation process and high product cost, and achieve the effects of simple production equipment requirements, low cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

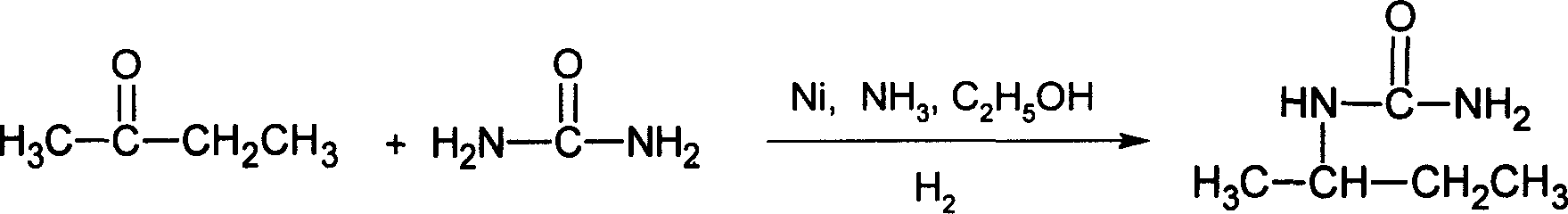

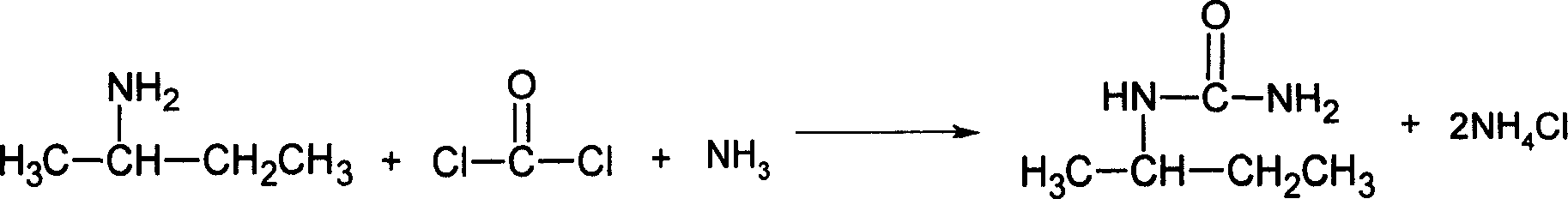

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

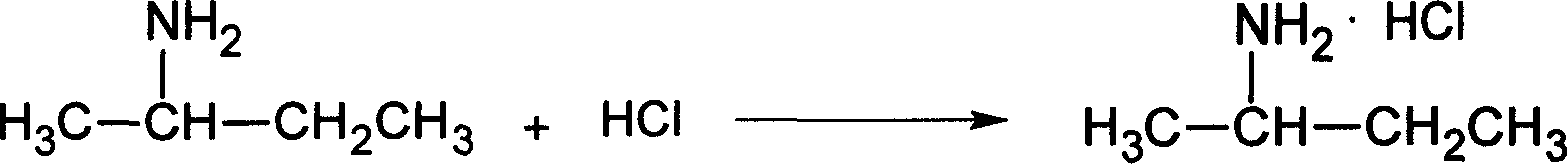

Embodiment 1

[0028] In a 250mL three-necked flask, add 70g of water, 0.5mol (36.5g) sec-butylamine, and 5 drops of methyl red ethanol solution, install a dropping funnel, a thermometer, and an electric stirrer, and place the three-necked flask in an ice-water bath . Add about 50g of 36-38% hydrochloric acid into the dropping funnel, start the electric stirrer, start dropping, control the dropping speed, make the temperature not exceed 20°C, stop dropping when the solution turns red, and stop stirring. Remove the ice-water bath and the dropping funnel, dry the surface of the three-necked bottle, add 1.5mol (90g) of urea, place the three-necked bottle in an electric heating bag, install a condenser tube, pass condensed water, start stirring, heat and reflux for 4 hours, stop heating, and wait for When the temperature drops below 80°C, pour the reaction liquid into a 250mL beaker under heat, and crystallize naturally for 0.5h, then place it in the refrigerator for crystallization for more tha...

Embodiment 2

[0030] In a 250mL three-necked flask, add 100g of water, 0.5mol (36.5g) sec-butylamine, and 5 drops of methyl red ethanol solution, install a dropping funnel, a thermometer, and an electric stirrer, and place the three-necked flask in an ice-water bath . Add about 49 g of concentrated sulfuric acid into the dropping funnel, start the electric stirrer, start dropping, control the dropping speed, make the temperature not exceed 20°C, stop dropping when the solution turns red, and stop stirring. Remove the ice-water bath and the dropping funnel, dry the surface of the three-necked bottle, add 1.5mol (90g) of urea, place the three-necked bottle in an electric heating bag, install a condenser tube, pass condensed water, start stirring, heat and reflux for 4 hours, stop heating, and wait for When the temperature drops below 80°C, pour the reaction liquid into a 250mL beaker under heat, and crystallize naturally for 0.5h, then place it in the refrigerator for crystallization for more...

Embodiment 3

[0032] On the 1000L enamel reaction kettle equipped with agitator, install condensing reflux device, temperature control device, freezing device, heating device, dripping device and pH value measuring device respectively. Add 280kg of water, 146kg of sec-butylamine, add 36-38% hydrochloric acid into the dripping device, start stirring, start the freezing device, start adding hydrochloric acid dropwise, control the dropping speed, so that the temperature does not exceed 20°C until the pH value reaches 5 At ~5.5 o'clock, stop dropping, stop stirring, and close the freezing device. Add 270 kg of urea, heat to reflux for 4 hours, stop heating, and crystallize naturally for 2 hours, then start the freezer, and crystallize at -1 ~ -5°C for more than 6 hours. The white solid was obtained by suction filtration, washed with 10 kg of cold water, drained, and weighed. Add water equivalent to 1.5 times the weight of the white solid, heat to dissolve, and crystallize naturally for 2 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com