Nano tube of cross linked polyphosphonitrile and preparation method thereof

A technology of nanotubes and polyphosphazene, which is applied in the field of cross-linked polyphosphazene nanotubes and its preparation, can solve the problems of cumbersome equipment and achieve good thermal stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 0.5 g (1.44 mmol) hexachlorocyclotriphosphazene and 1.08 g (4.32 mmol) 4,4'-dihydroxydiphenyl sulfone into a 500 ml flask, then add 200 ml of anhydrous tetrahydrofuran, stir to dissolve, and then Add 0.87 g (8.64 mmol) of triethylamine in 50 ml of anhydrous tetrahydrofuran solution into the above reactor, and use an ultrasonic cleaner to vigorously stir the reaction for half an hour at 25 ° C. After the reaction is completed, filter the crude The product was washed three times with tetrahydrofuran, then three times with deionized water, and finally dried in a vacuum oven for 24 hours to obtain 1.17 g of cross-linked polyphosphazene nanotubes, with a yield of 92% based on hexachlorocyclotriphosphazene.

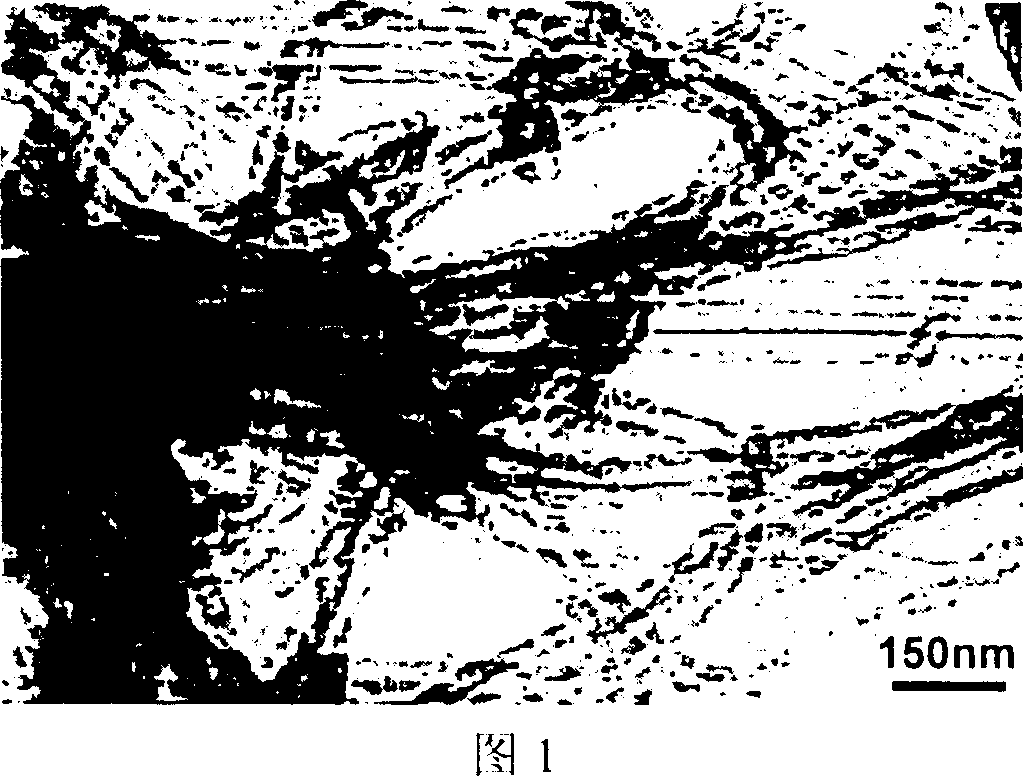

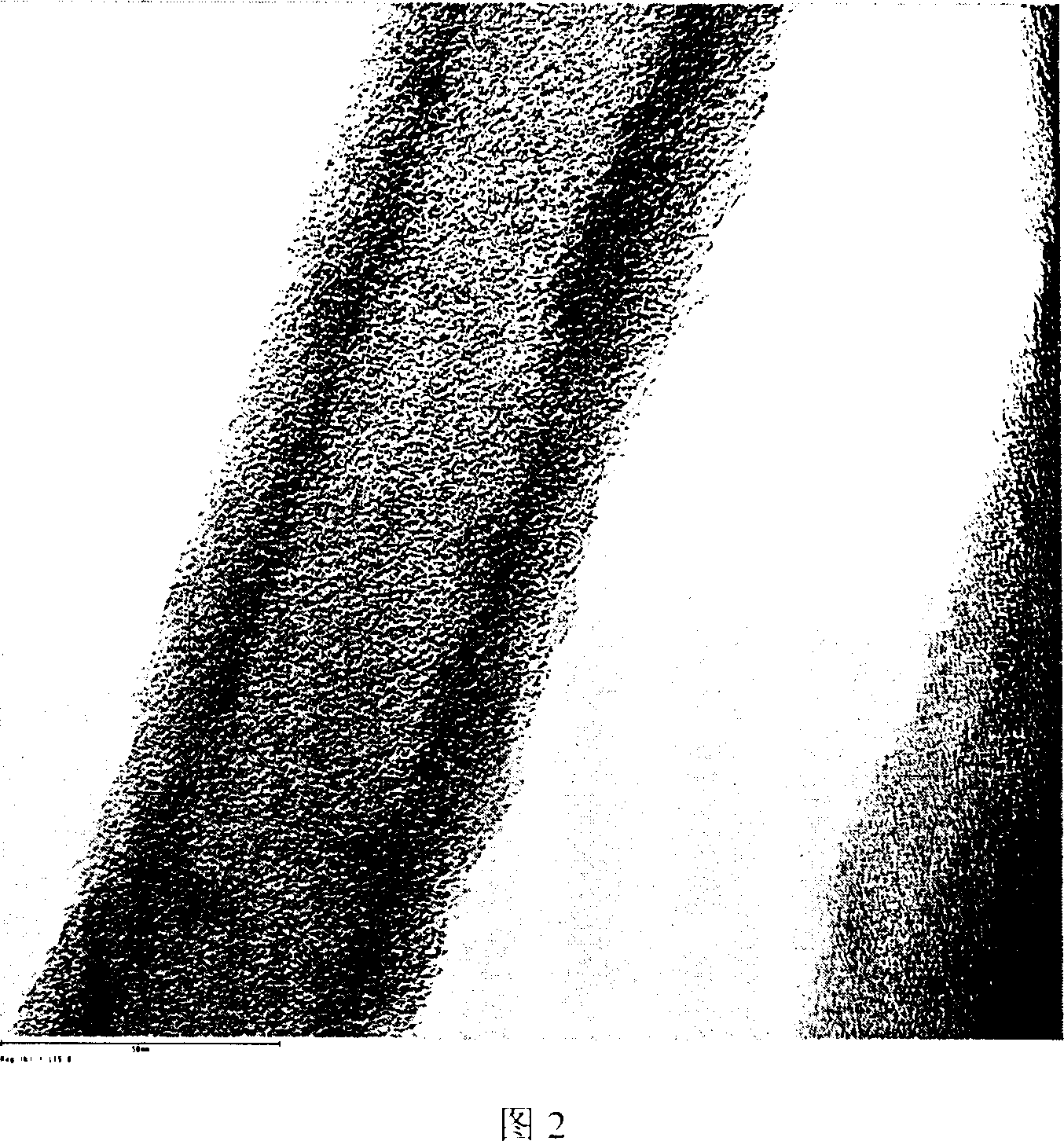

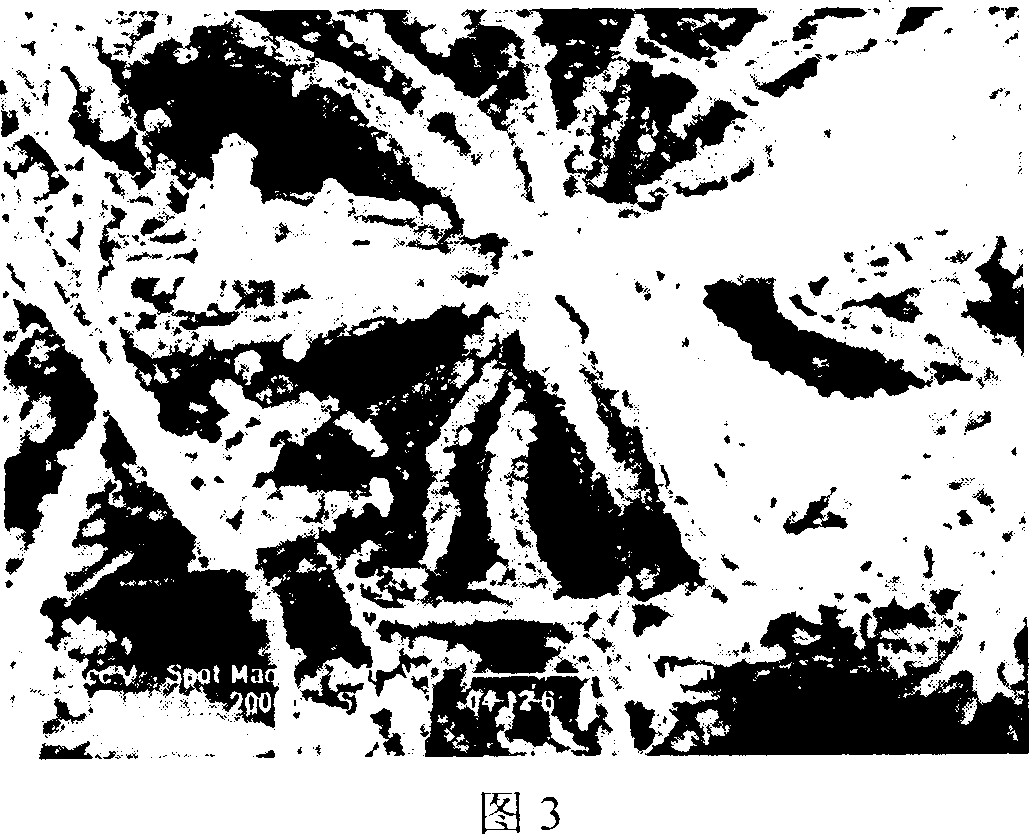

[0023] Fig. 1 is the transmission electron micrograph of gained crosslinked polyphosphazene nanotube, Fig. 2 is the high-resolution transmission electron microscope photograph of crosslinked polyphosphazene nanotube, Fig. 3 is the field emission scanning electron micr...

Embodiment 2

[0029] Add 0.5 g (1.44 mmol) hexachlorocyclotriphosphazene and 1.08 g (4.32 mmol) 4,4'-dihydroxydiphenyl sulfone into a 500 ml flask, then add 75 ml of anhydrous tetrahydrofuran, stir to dissolve, and then Add 0.87 g (8.64 mmol) of triethylamine in 20 ml of anhydrous tetrahydrofuran to the above reactor, and react with vigorous mechanical stirring for 1 hour at 25 ° C. After the reaction is completed, filter the crude product with tetrahydrofuran Washed three times, then washed three times with deionized water, and finally dried in a vacuum oven for 24 hours to obtain 1.20 g of cross-linked polyphosphazene nanotubes, with a yield of 94% based on hexachlorocyclotriphosphazene. Electron microscope photos show that nanotubes are single-walled amorphous structures with a diameter of 15-25 nanometers, an aspect ratio of 20-40, and a wall thickness of 5-10 nanometers. Spectral analysis shows that its structure is hexachlorocyclotriphosphazene and 4,4 The cross-linked condensation st...

Embodiment 3

[0031] The equipment and preparation process described in Example 1 were used, except that the reaction temperature was carried out at the reflux temperature of tetrahydrofuran, and the yield was 89% based on hexachlorocyclotriphosphazene. The analysis of the experimental results shows that the nanotube is a single-walled amorphous structure with a diameter of 60-80 nanometers, an aspect ratio of 50-60, and a wall thickness of 15-20 nanometers. Its structure is hexachlorocyclotriphosphazene and 4,4'- The cross-linked condensation structure of dihydroxydiphenyl sulfone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com