Multistage impulsion type steam turbine with damp being removed and heat being regained inside machine

A steam turbine and impulsive technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of uneconomical economy, high cost, complex structure, etc., achieve the effect of small pipeline, low cost, and widen the parameter range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

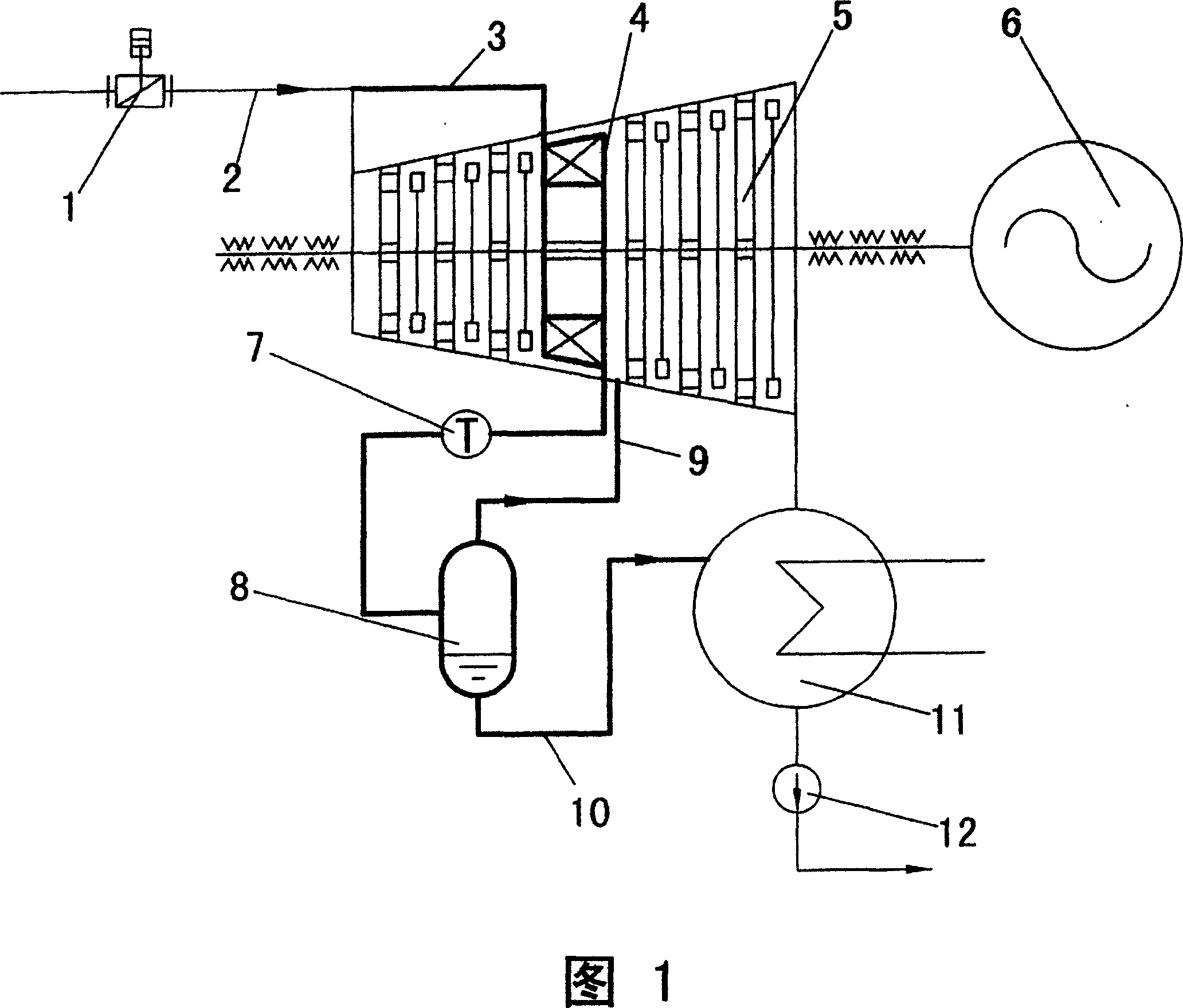

[0023] The thermal system diagram of the embodiment of the present invention as shown in Fig. 1 (in the figure we only show one stage of internal reheating, in fact two or even multiple stages of internal reheating can be set as required). A reheat steam pipe 3 with a small diameter (such as DN80mm) is connected to the main steam pipeline 2 behind the main steam valve 1, and this pipe supplies 3% to 8% of the total steam to the interstage located in the steam turbine cylinder Steam reheater4. After the steam releases heat in the reheater 4, the saturated condensed water is controlled by the steam trap 7 and enters the hydrophobic expansion tank 8, where the condensed water depressurizes and flashes out part of the steam to enter the steam turbine 5 to expand and work through the steam pipe 9. The low-pressure saturated water in the hydrophobic expansion tank 8 is discharged to the condenser 11 through the pipe 10 to mix with the condensed water of the mainstream working steam,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com