Multifunctional charging mechanism

A multi-functional, rack-mounted technology, applied to conveyors, agricultural machinery and implements, loading/unloading, etc., can solve problems such as unsuitable for small-scale loading operations, high labor intensity for operators, and certain difficulties. Achieve the effects of simple and reasonable structure, easy promotion and application, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

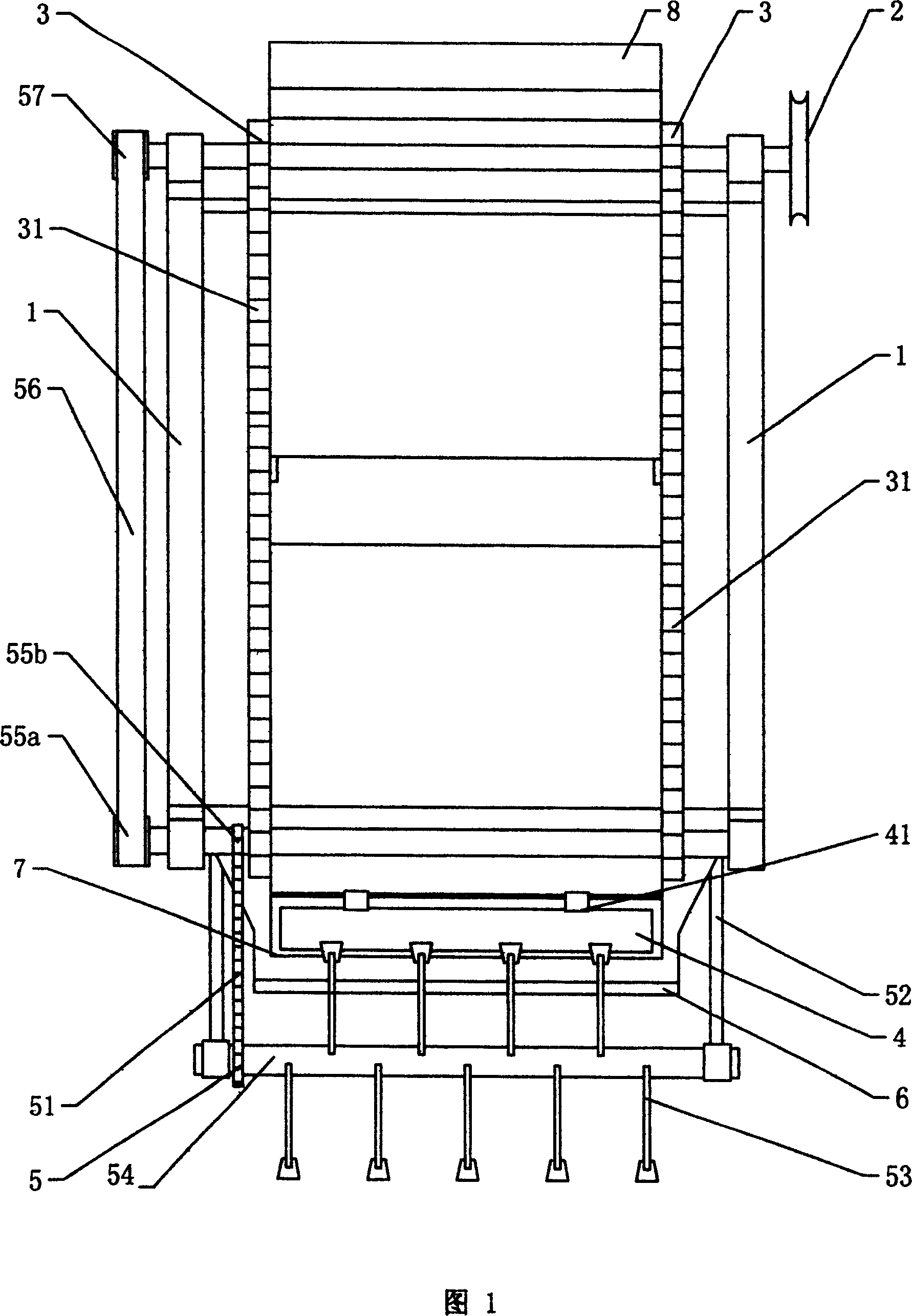

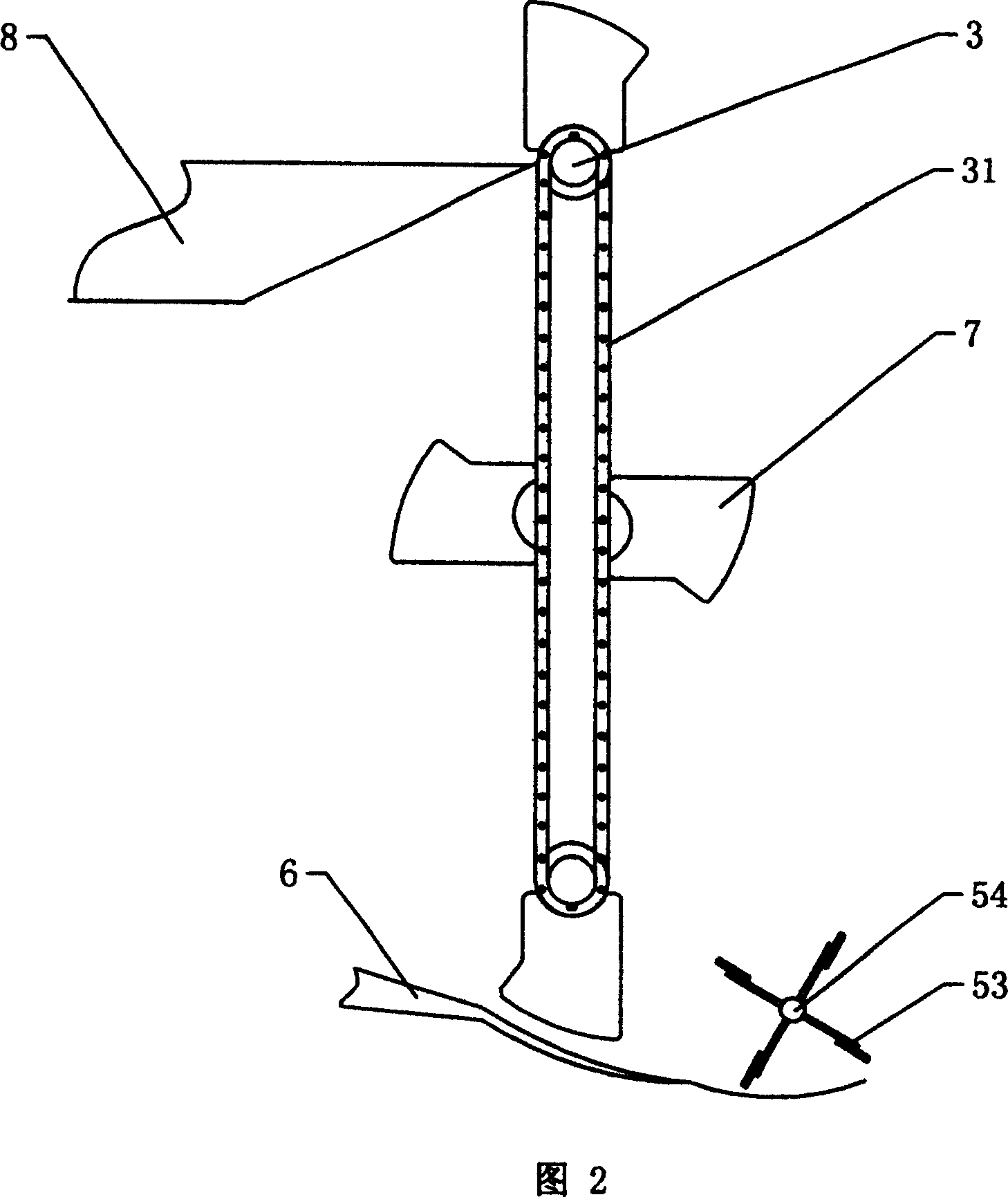

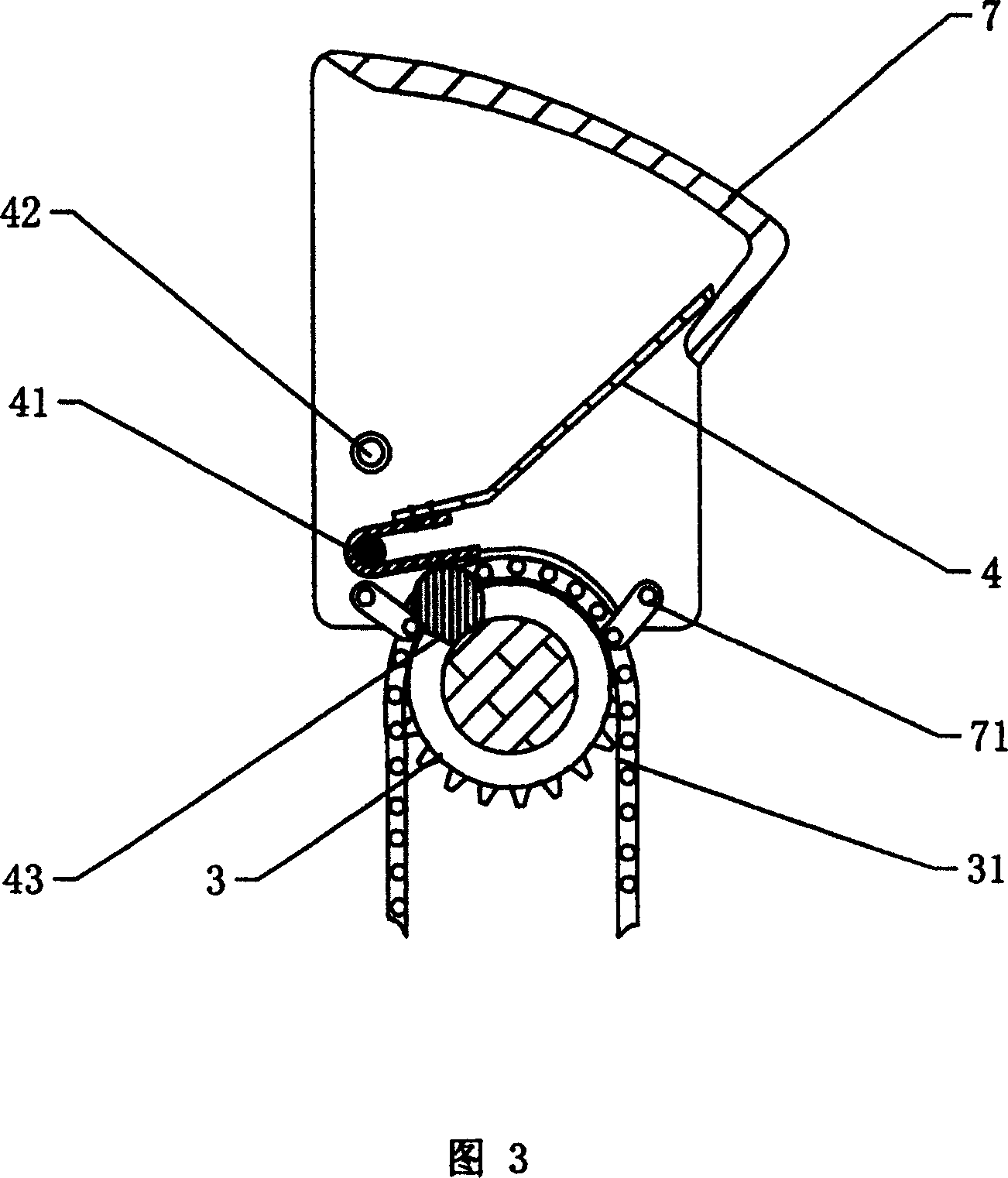

[0014] With reference to Fig. 1, Fig. 2, a kind of multifunctional feeding mechanism of the present invention is: comprise frame 1, the power transmission device that is installed on the frame 1, the feeding device that is connected with power transmission device, power transmission device drives upper The feeding device runs, and a feeding device is installed on the frame 1, and an automatic unloading device that can automatically unload the loaded material is installed on the feeding device. The power transmission device is that a power wheel 2 is installed on the frame 1, two feeding sprockets 3 coaxial with the power wheel 2 are respectively installed on both sides of one end of the frame 1, and the other side of the frame 1 Two feeding sprockets 3 are respectively installed on both sides of one end, and the two feeding sprockets 3 are also on the same shaft, and the feeding sprockets 3 on the same side at both ends of the frame 1 are respectively connected by a chain 31 tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com