Method and material for moducing blocking type liquid food soft package material

A technology of liquid food and production method, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc. It can solve the problems of complex and cumbersome processing procedures, poor heat sealing performance, low friction coefficient, etc., and achieve reduction Effects of manufacturing steps, low coefficient of friction, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

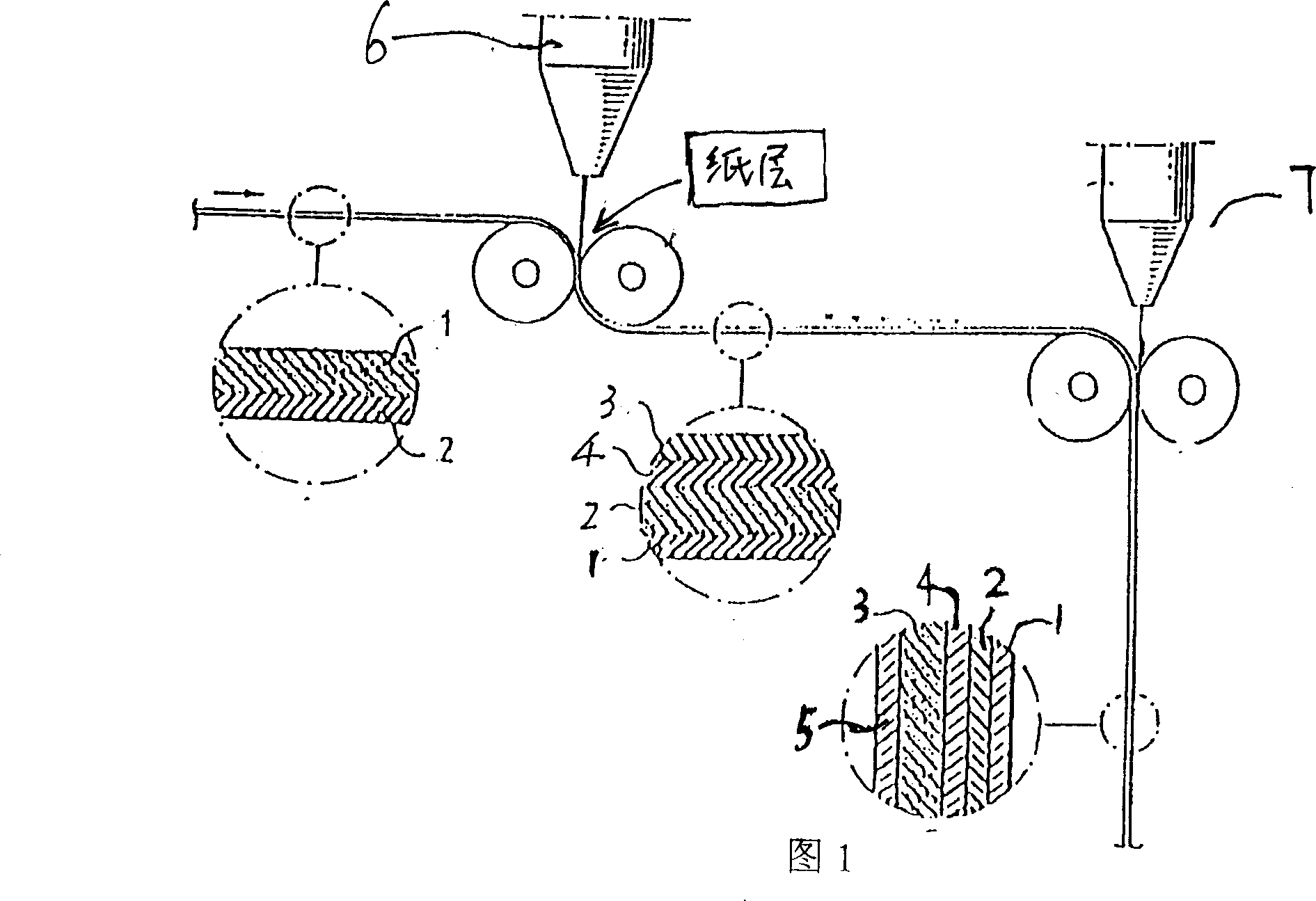

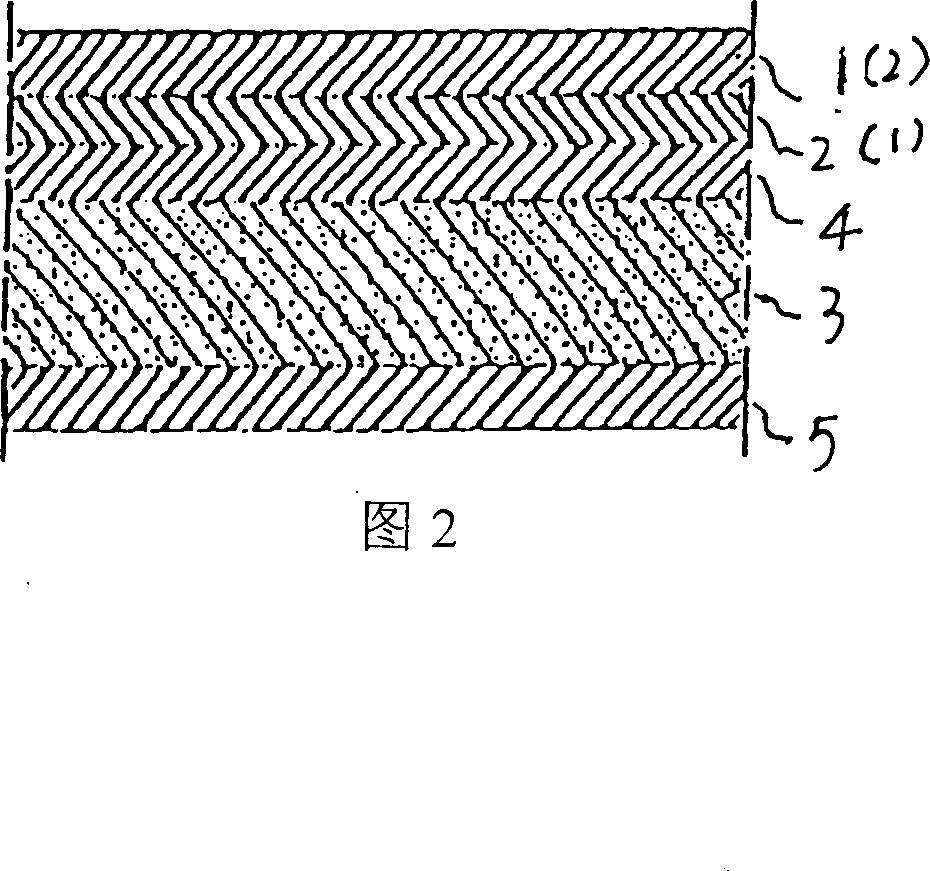

[0019] As shown in Figures 1 and 2, a method for manufacturing a barrier liquid food flexible packaging material. The manufacturing steps are as follows: 1. The coated substrate (part of Figure 1) is initially unrolled, and the substrate layer 1 is polymerized. Ester film, polyethylene film or polypropylene film, and the coating layer 2 is made of polyvinylidene chloride or nylon resin. 2. Extrusion compounding: extruding and compounding the above-mentioned substrate, paper and polyethylene in a molten state into a compound of substrate layer 1, coating layer 2, paper layer 3 and polyethylene layer 4. Layer, the temperature during extrusion is 280°C-350°C, at which temperature the polyethylene is in a molten state; the polyethylene is low-density polyethylene, metallocene polyethylene or linear polyethylene. 3. The composite layer compounded in the second step is extruded and compounded with the polyethylene in the molten state through the No. 2 extruder 7, and then a layer of pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com