Surface-mount antenna and communication device with surface-mount antenna

A surface-mounted, antenna technology, used in devices that make antennas work in different bands at the same time, antenna supports/mounting devices, antennas, etc., can solve the problem of capacitive coupling enhancement, inability to achieve multiple resonance conditions, resonance mutual interference, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

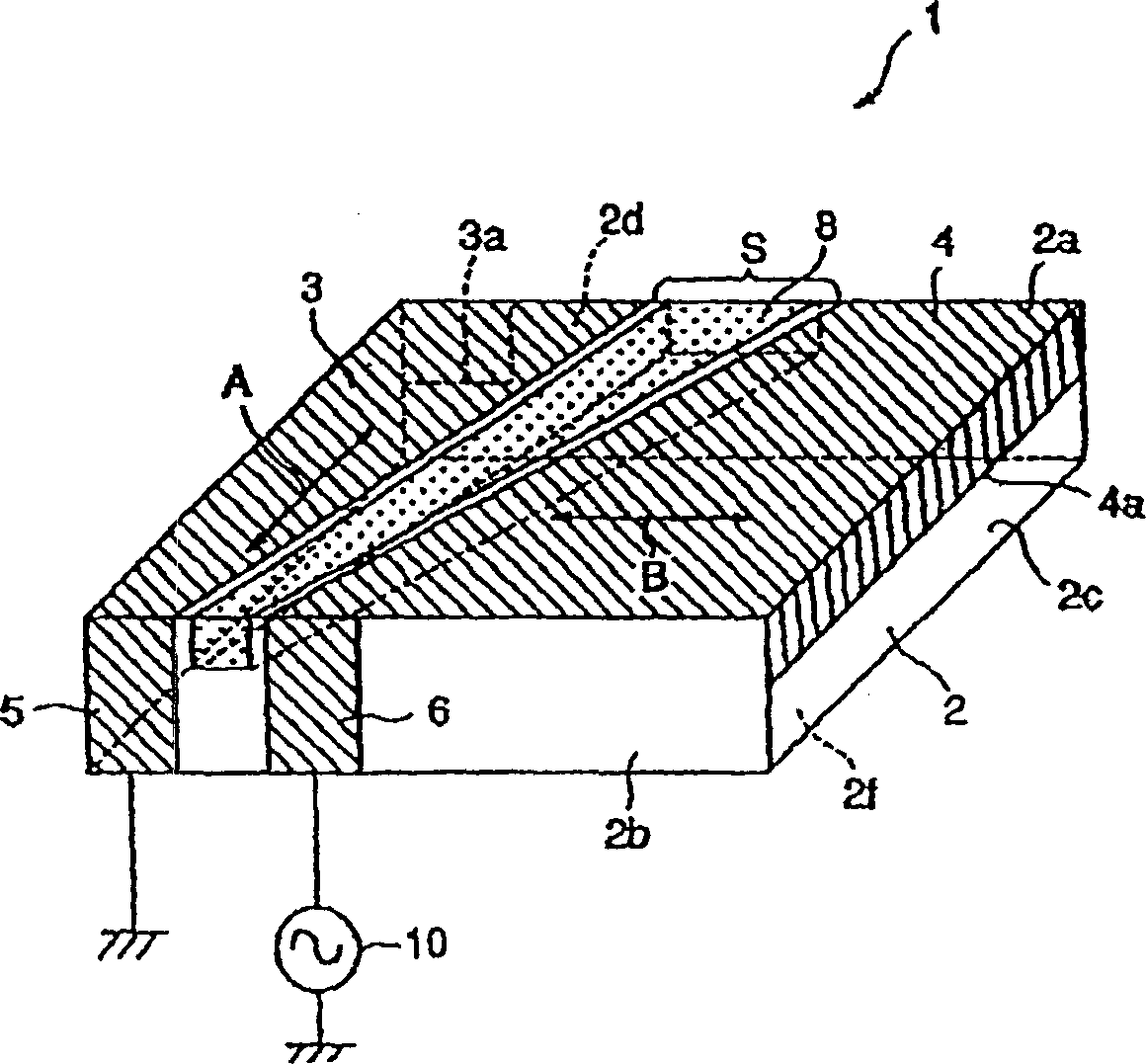

[0029] figure 1 is a schematic perspective view of a surface mount type antenna related to Embodiment 1 of the present invention. figure 1 The shown surface mount type antenna 1 has a dielectric base layer 2; on the top surface 2a of the dielectric base layer 2, a non-power supply terminal radiation electrode 3 as a first radiation electrode and a power supply terminal radiation electrode 4 as a second radiation electrode are formed. , with a space in between. In this Embodiment 1, the space S is formed between the non-power supply terminal radiation electrode 3 and the power supply terminal radiation electrode 4 such that its longitudinal sides are inclined (for example, at 45 degrees) with respect to each side of the top surface 2 a of the dielectric underlayer 2 . horn).

[0030] On one side surface 2b of the dielectric base layer 2, a ground electrode 5 connected to the non-power supply radiation electrode 3 and a power supply electrode 6 connected to the power supply ...

Embodiment 2

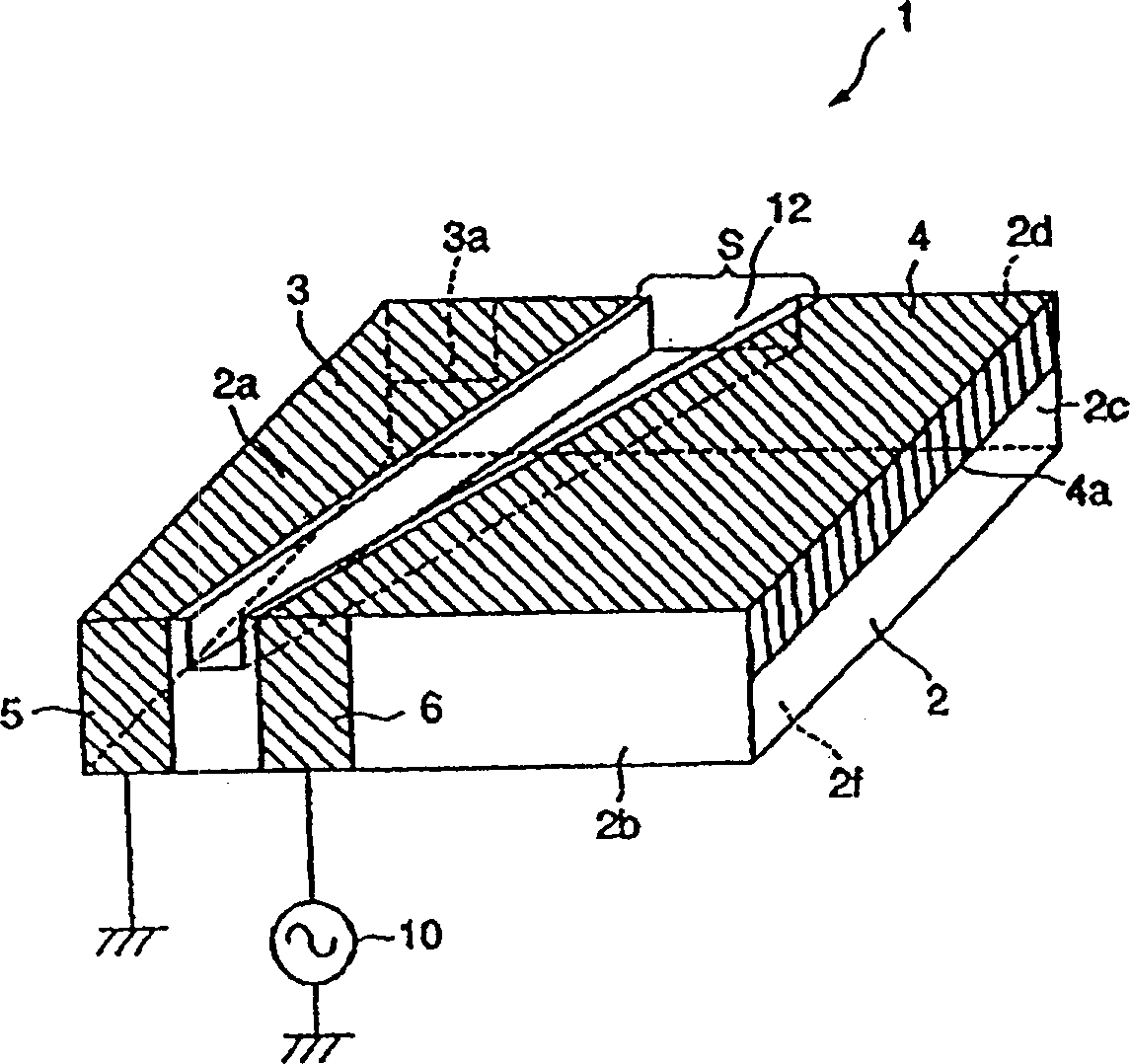

[0042] Such as figure 2 As shown, the difference between Embodiment 2 and the above Embodiment 1 in terms of features is that a groove 12 is provided as a capacitive coupling device instead of between the radiation electrode 3 at the non-power supply end and the radiation electrode 4 at the power supply end. A dielectric constant adjusting material portion 8 is provided. Other features are the same as those of Embodiment 1. In Embodiment 2, the same reference numerals are given to the same components as those of Embodiment 1, and repeated description of common components therebetween will be omitted.

[0043] As in the case of Embodiment 1, the surface mount antenna provided by Embodiment 2 is also arranged to weaken the capacitive coupling between the radiation electrode 3 at the non-power supply end and the radiation electrode 4 at the power supply end. In particular, the grooves 12, which are characteristic of Embodiment 2, are provided along the respective longitudinal ...

Embodiment 3

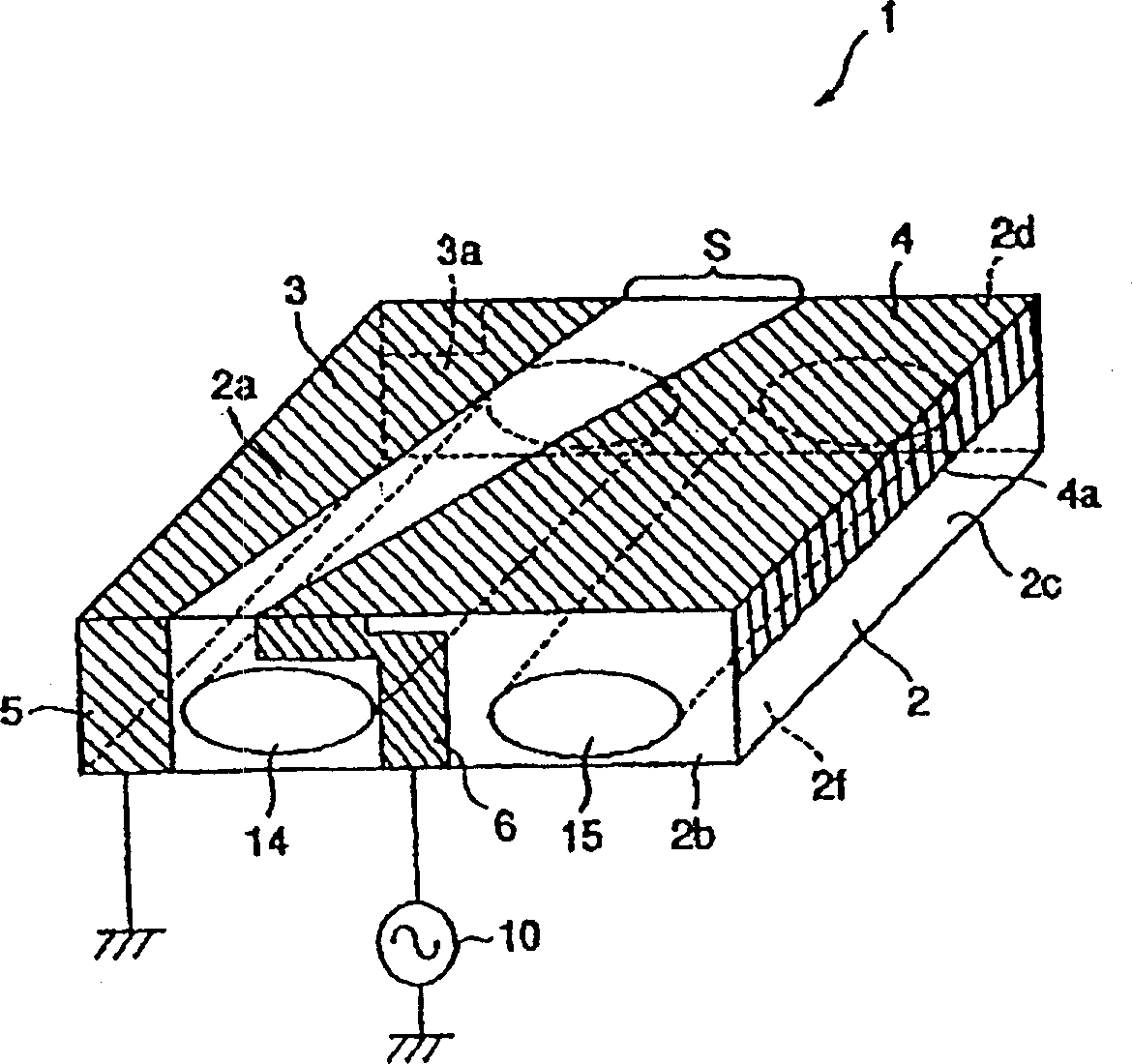

[0046] Such as image 3 As shown, Embodiment 3 is characterized in that there are hollow portions 14 and 15 in the dielectric bottom layer 2 as capacitive coupling adjusting means. Other features are the same as those of the above-mentioned embodiments. In this embodiment 3, the same reference numerals are given to the same parts as those of the above-mentioned embodiment, and repeated description of common parts therebetween will be omitted.

[0047] Such as image 3 As shown, in Embodiment 3, the hollow portion 14 is located in the region of the non-power-supply-side radiation electrode 3 in the dielectric bottom layer 2, and the hollow portion 15 is provided together with the hollow portion 14 at a distance therefrom.

[0048] According to the third embodiment, since the hollow portion 14 is formed in the region of the non-power supply side radiation electrode 3 within the dielectric substrate 2, the hollow portion 14 allows the capacitance between the non-power supply si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com