Method and apparatus for making a multilayer coating

A coating and coating layer technology, which is applied in the rearrangement of coating materials, papermaking, coating, etc., can solve the problems of high product prices and increase of final prices, and achieve investment and raw material cost savings and reduce damage pressure Danger of bare rolls, effect of short machine length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following, the terms coating and coating formulations must be understood as meaning all methods and formulations in which mixtures comprising pigmented materials are used for the treatment of webs. In addition to these ingredients, the term web treatment agent is used when the broader reference also covers other ingredients used in web treatment such as surface sizing.

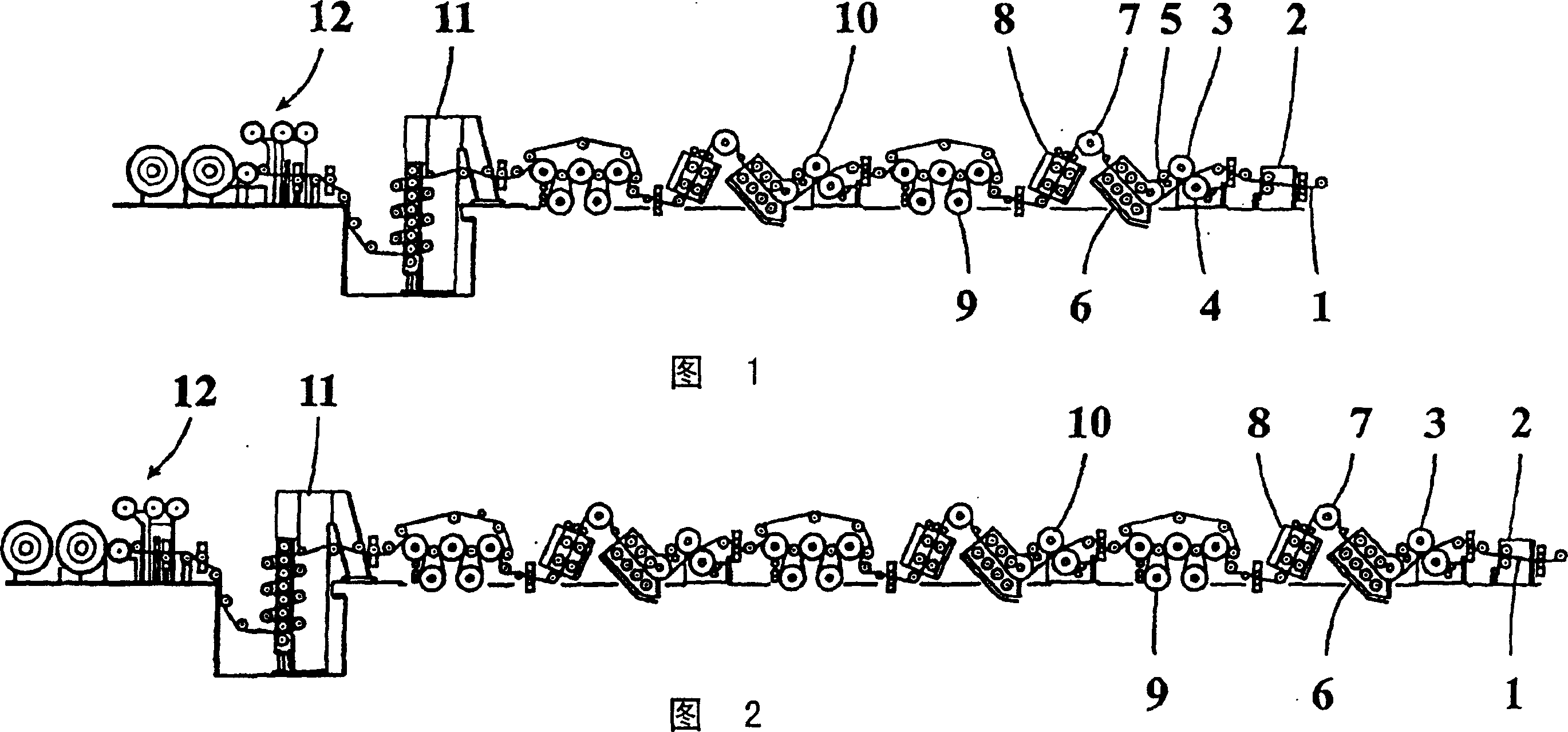

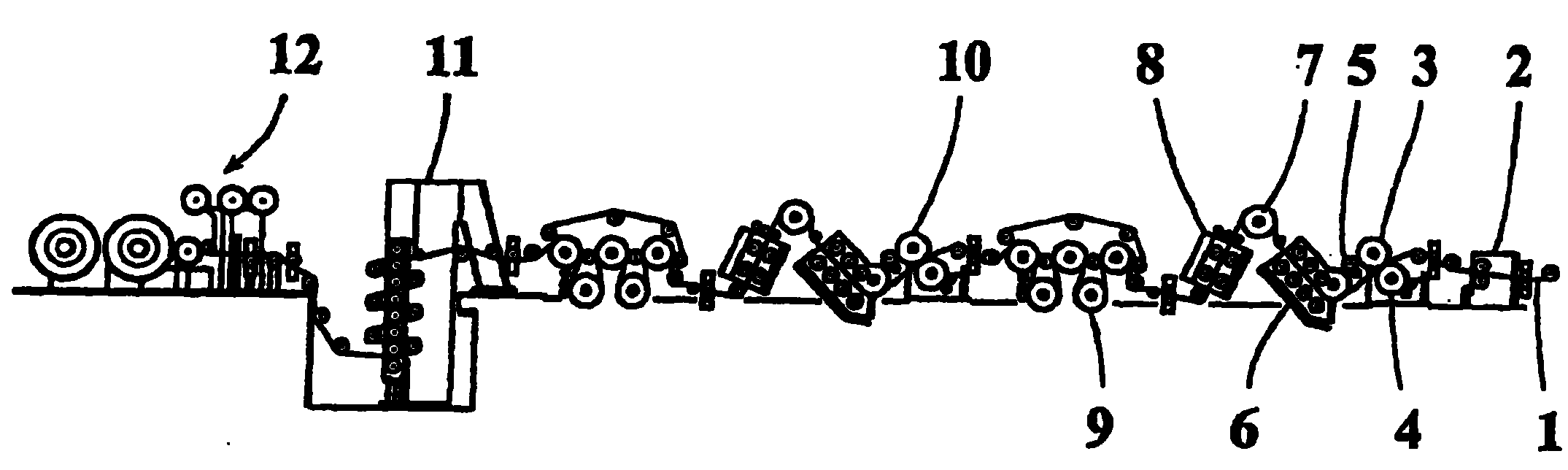

[0035]Referring to Figure 1, there is shown a coater layout for making paper coated on both sides by two-layer coating. Although, this coater layout can be very advantageously used to set up an in-line system with a paper machine, it is also suitable to work as an off-line coater combined with an unwinder.

[0036] In this arrangement, the first unit is the pre-calender 2, in which the surface of the web is smoothed for later processing. The pre-calender may be a machine calender, soft-nip calender or other type of calender capable of producing a suitable web surface smoothness. Aspects to cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com