Oil collector

An oil collector and fuel injector technology, which is applied in the field of oil collectors, can solve the problems of complex measurement accuracy, unfavorable promotion and application, high cost, etc., and achieves the effects of simple processing circuit, strong anti-interference ability and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

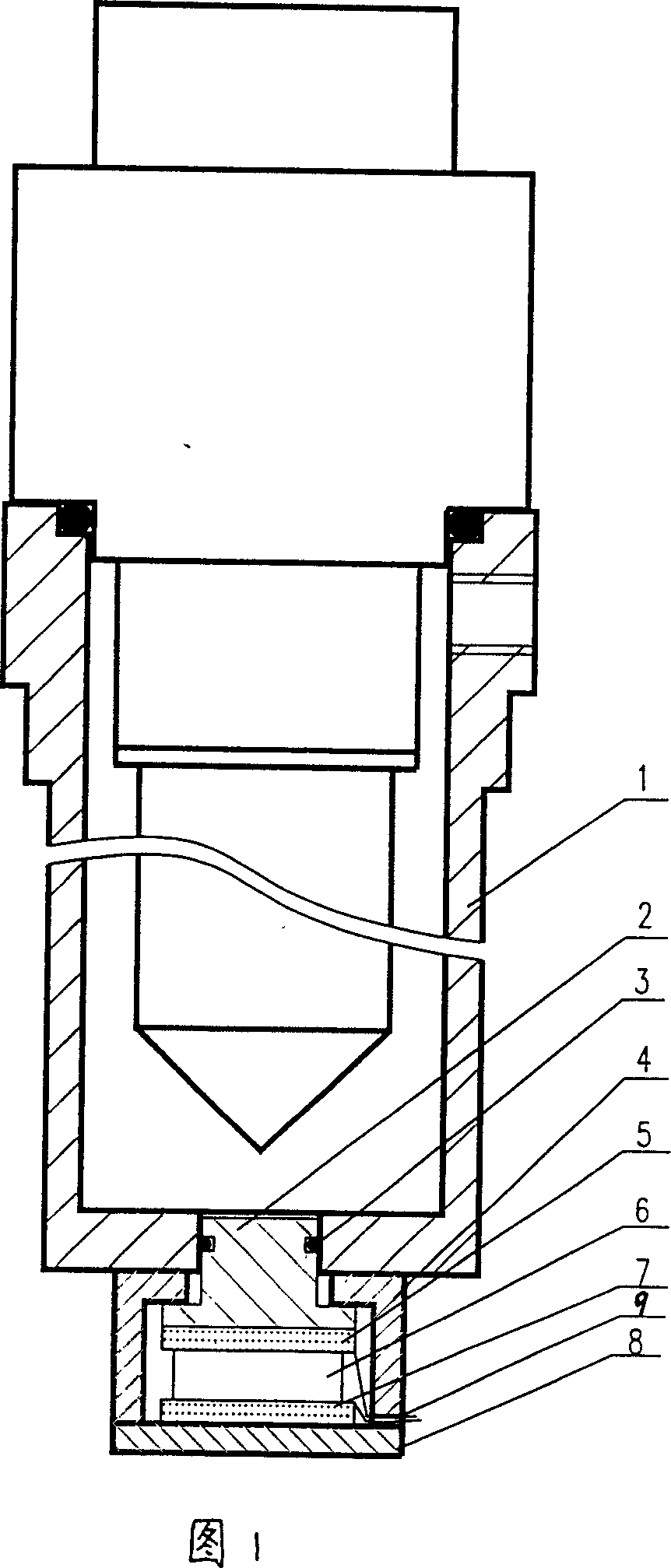

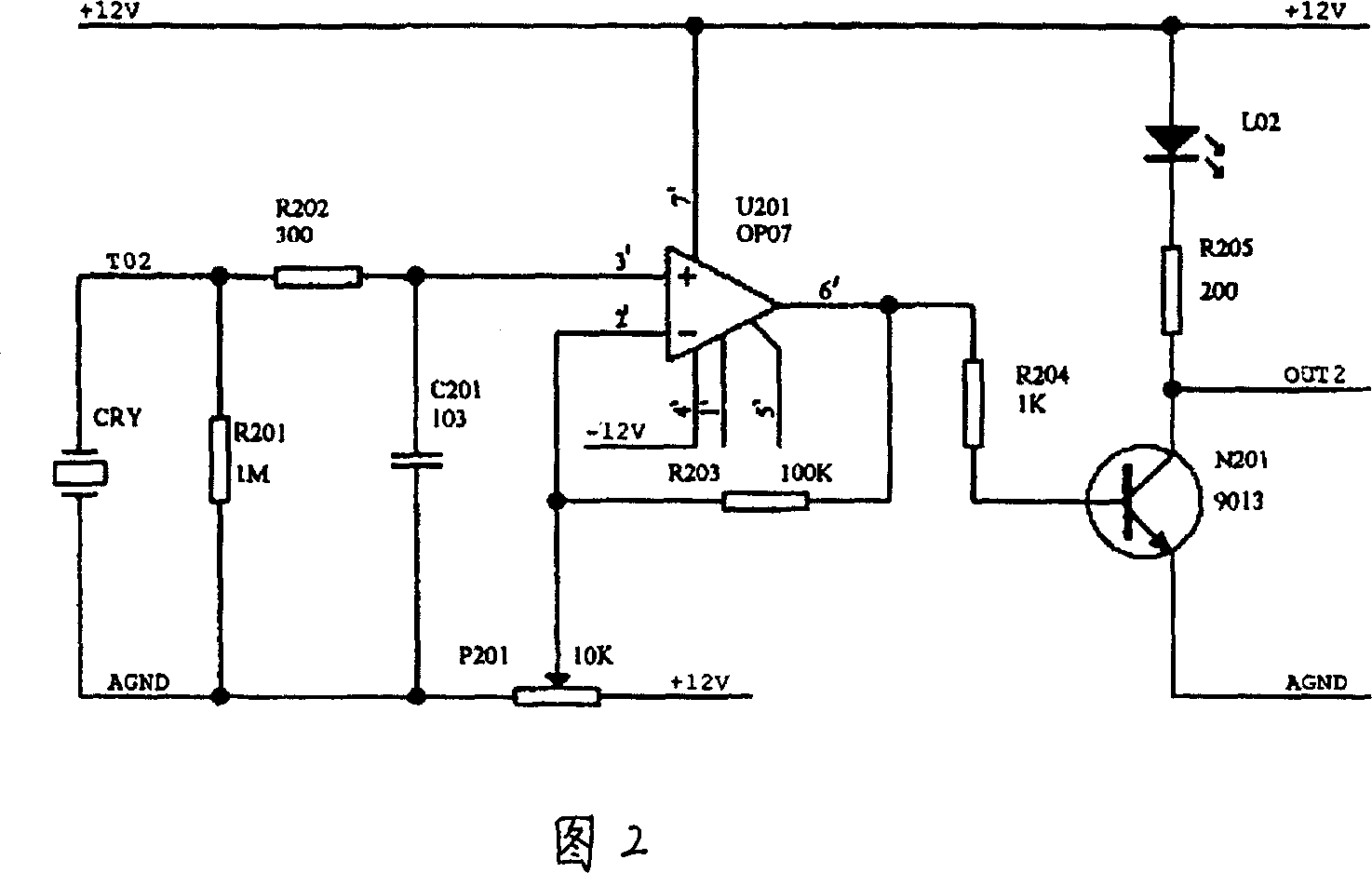

[0008] As shown in Figure 1, a fuel injection sensor is installed on the fuel collector 1 of the present invention, wherein the fuel injection sensor is a piezoelectric fuel injection sensor, and the piezoelectric fuel injection sensor includes an induction column 2 made of an insulating material, The induction column 2 is inserted into the socket provided at the bottom of the oil collector. A sealing ring 3 is installed between the induction column 2 and the socket. Sheet 7 and pressure plate 8, the above-mentioned components are packaged in the sensor housing 4, the upper conductive sheet 5 is in contact with the pressure plate 8 through high-impedance insulated wires, and the lower conductive sheet 7 is in contact with the pressure plate 8, and the wires are connected from the gap 9 on the metal sensor housing 4 respectively. lead out. When the injector injects oil, the oil pressure in the oil collector 1 rises, and the induction column 2 transmits this pressure to the piez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com