Apparatus and method for an integrated circuit having high Q reactive components

A technology of integrated circuits and circuits, which is applied in the direction of printed electrical components, electrical components, circuits, etc., and can solve problems such as reducing the performance of functional circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

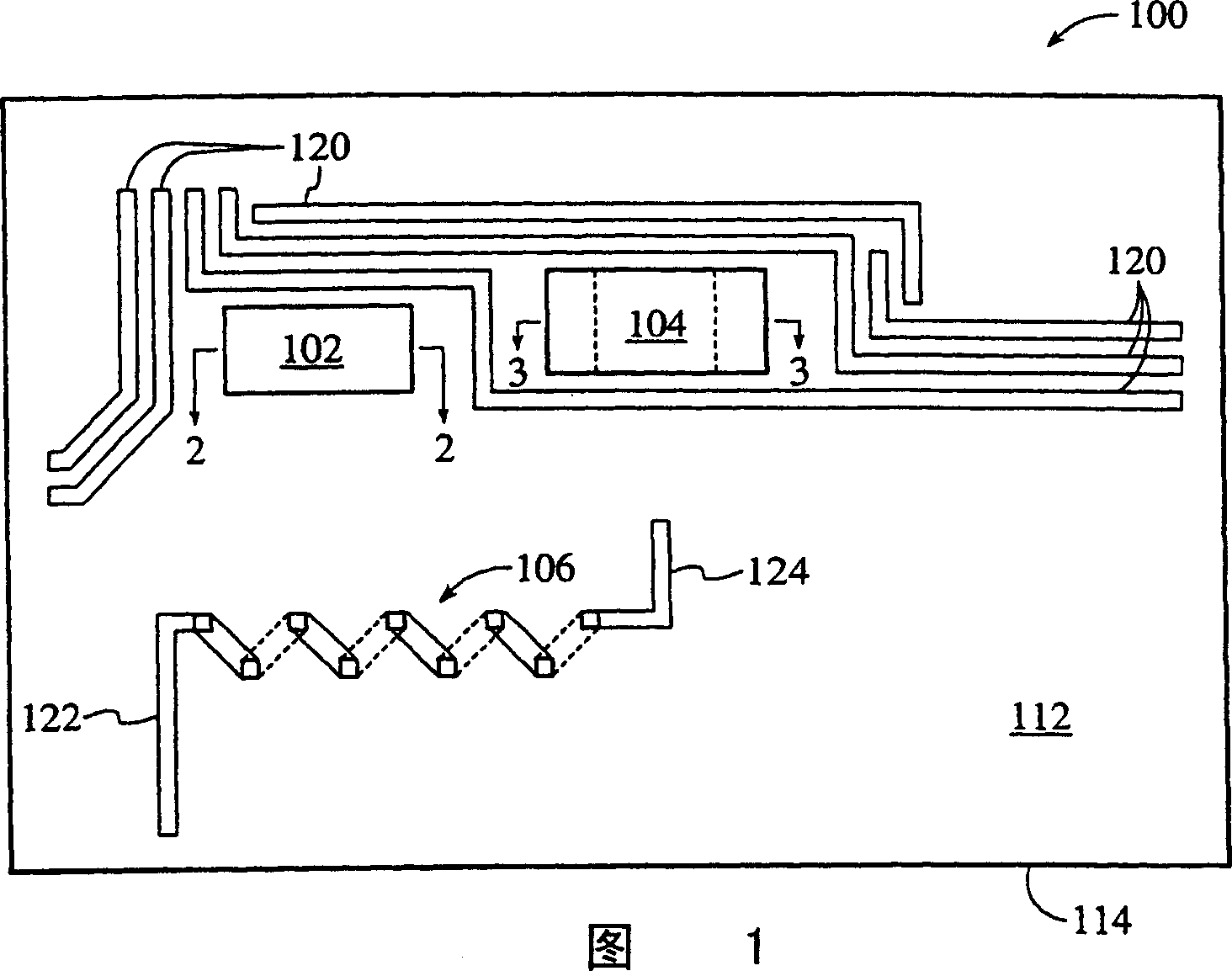

[0017] Figure 11 A typical ball grid IC package is shown, including a chip 1102 mounted on a substrate 1112 and encapsulated by an encapsulant 1110. Turning to Figure 1, a laminated substrate 114, configured in accordance with a preferred mode of the present invention, includes a single or multiple layers of interconnected metal layers, each layer being separated by a layer of insulating material. The uppermost interconnect layer shown in FIG. 1 includes a plurality of interconnect traces 120 and passive elements 102-106. Specifically, elements 102 and 104 are capacitors, while element 106 is an inductor. Inductor 106 can be seen to include traces 122 and 124 . This interconnect layer is disposed on the upper surface 112 of the substrate 114 .

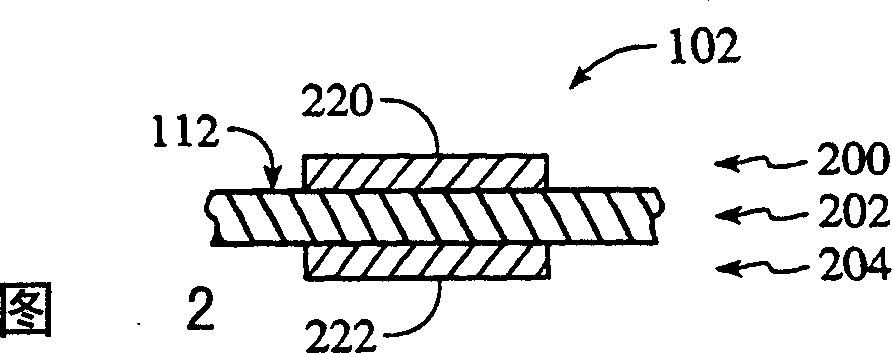

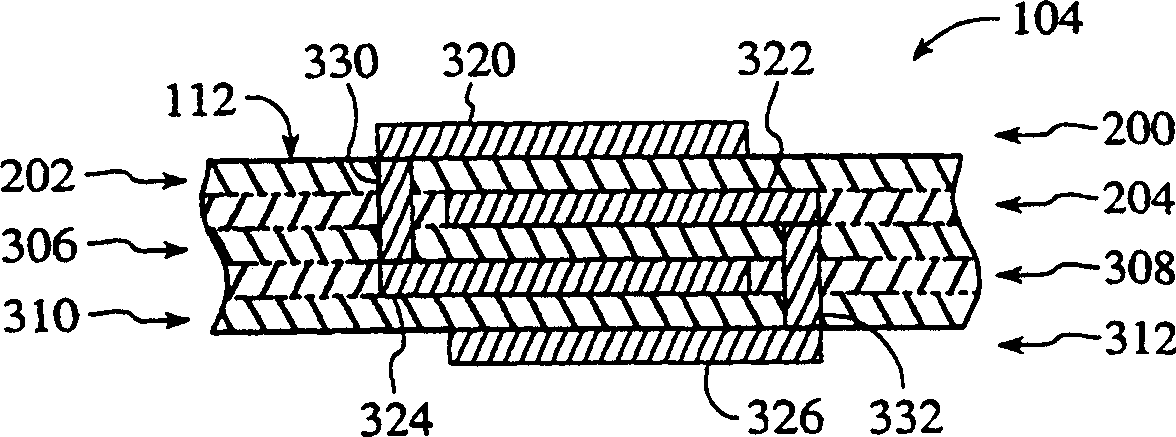

[0018] Referring to FIG. 2 , a side view of capacitor 102 taken along line 2 - 2 in FIG. 1 shows a portion of substrate 114 . A metal layer 200 is placed on top of insulating layer 202, which is also placed on another metal layer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com