Variable positive displacement compressor

A positive displacement compressor and a compressor technology, applied in the field of manufacturing such compressors, can solve the problems of difficult shape, difficulty in reducing the weight of the rotor 103 and the hinge mechanism 107, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

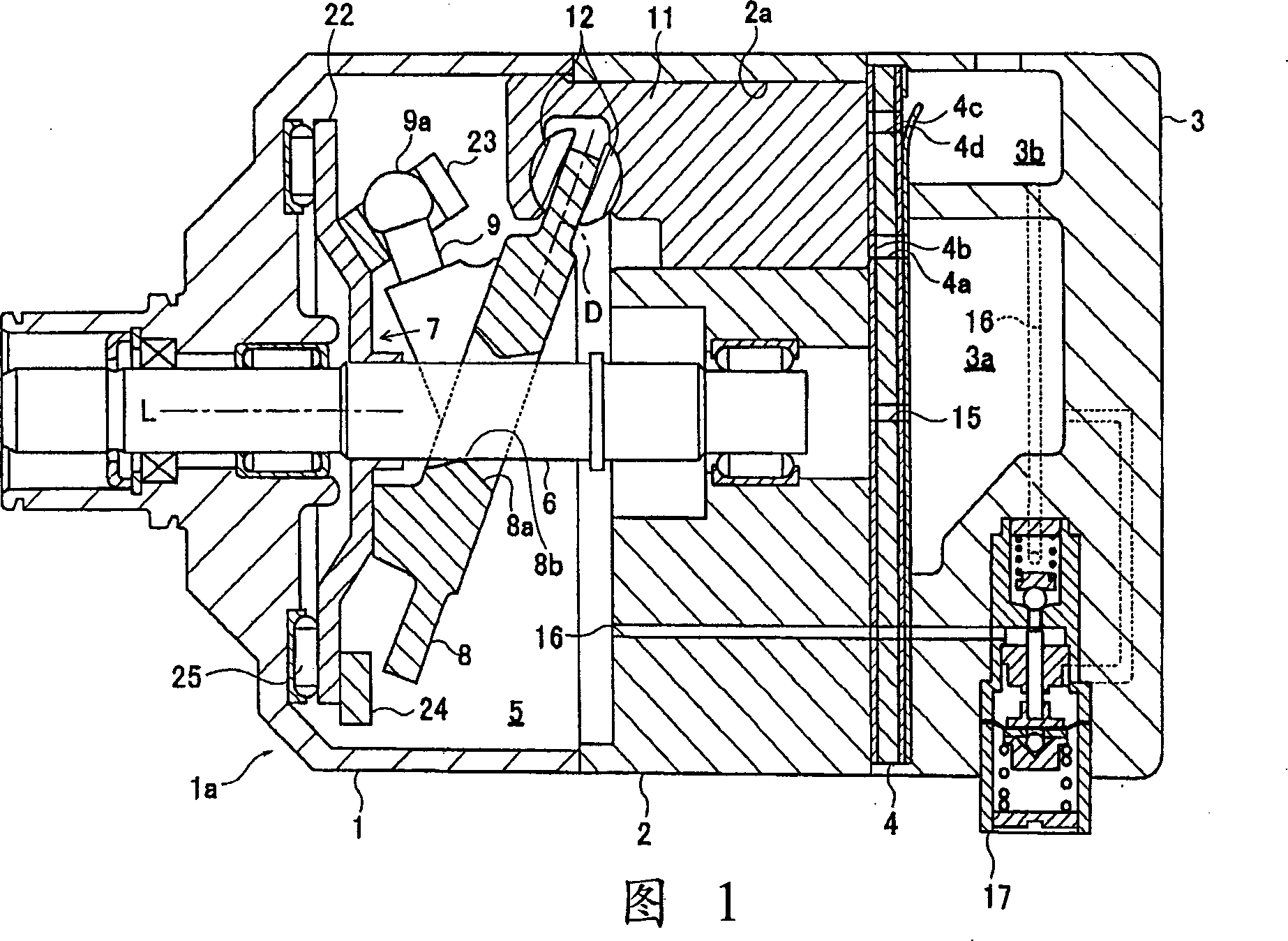

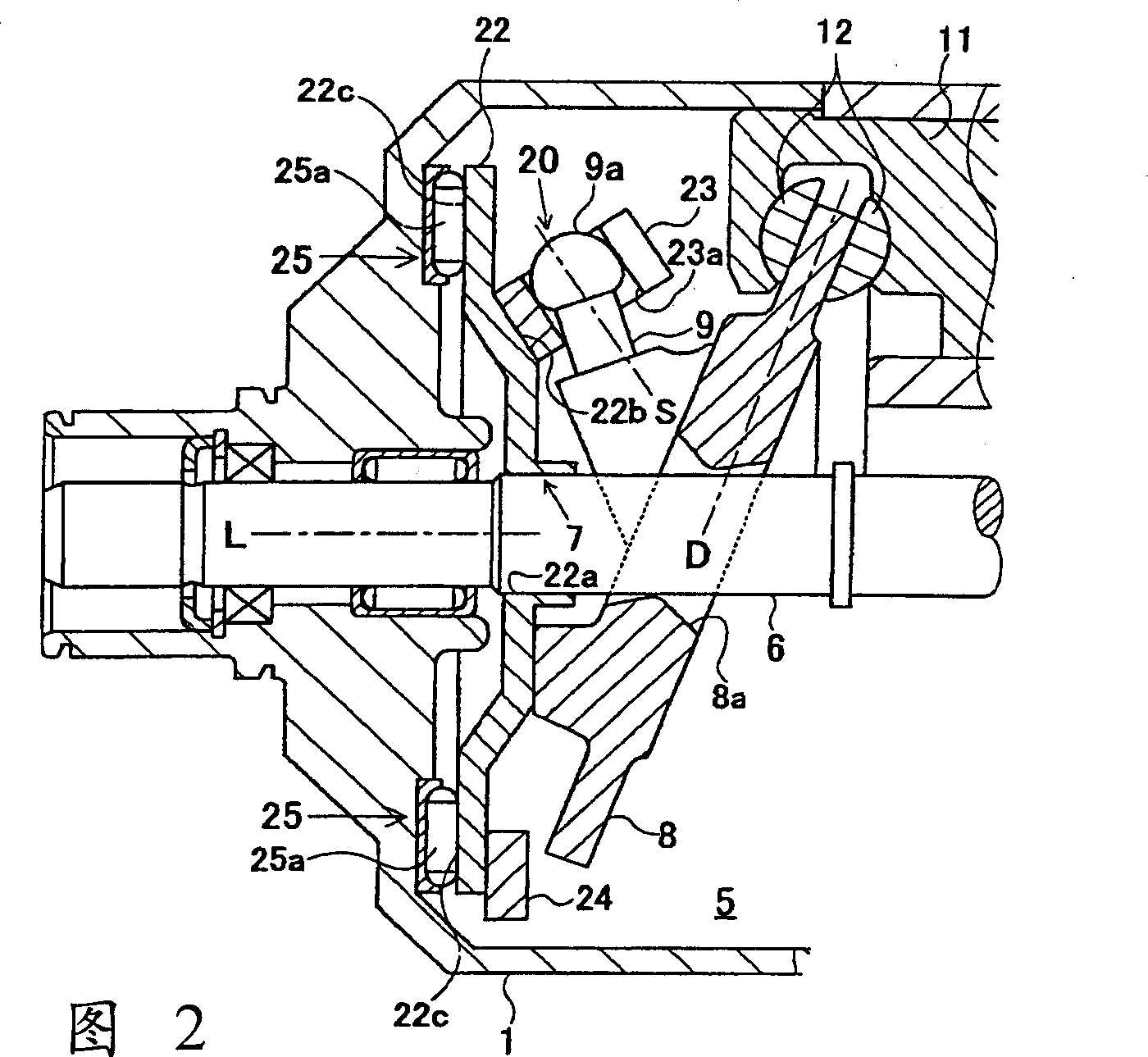

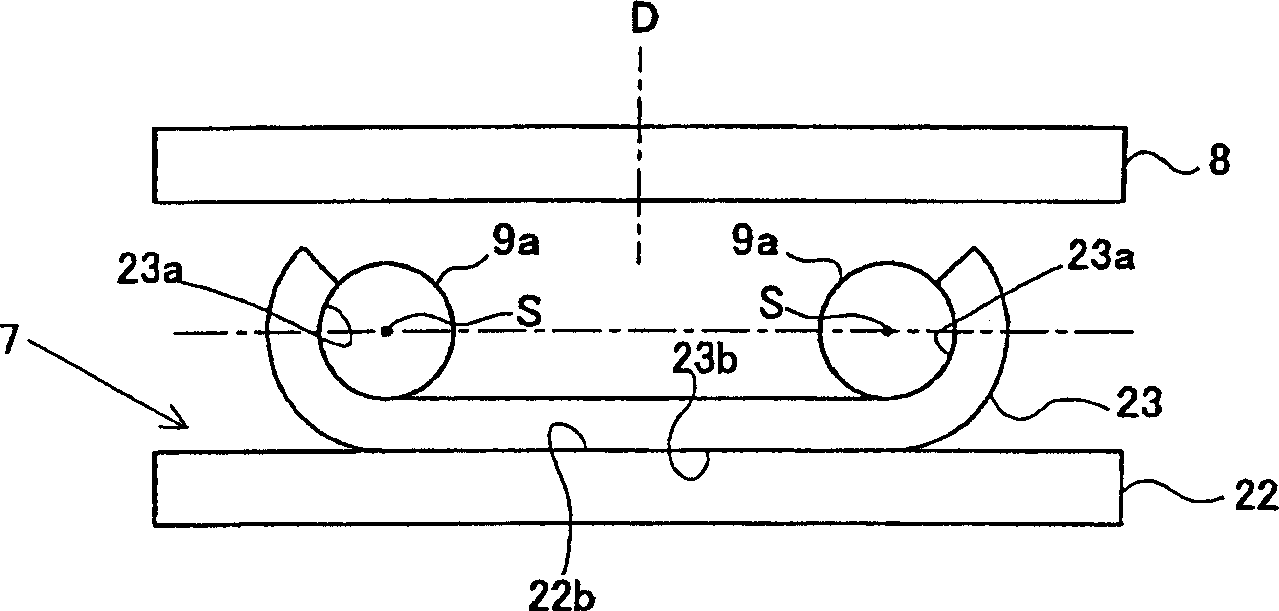

[0023] The variable displacement compressor of the present invention includes a drive shaft, a swash plate, a piston, a rotor and a hinge mechanism. The swash plate is mounted obliquely on the drive shaft. The piston may be located in the cylinder bore, the end of which is connected to the peripheral edge of the swash plate by means of pads. The piston can reciprocate in the cylinder bore with the rotation of the swash plate to compress the refrigerant. The inclination angle of the swash plate can be changed. When the tilt angle changes, the compressor output flow also changes. The rotor can be coupled with and rotate with the drive shaft.

[0024] The rotor also includes functional components, such as a rotating disk, a guide member provided on the rotating disk, and a counterweight. The counterweight is used to adjust the balance of the center of gravity of the rotating rotor. According to the invention, at least one functional part is stamped and stamped from a sheet m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap