Paint with characteristic infrared absorption peak matching with that of water

An infrared absorption and coating technology, applied in the coating and other directions, can solve the problems of large energy loss, large energy consumption, uneven dehydration, etc., and achieve the effect of improving the drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: use silicon carbide powder, take 65% of the material; pure quartz powder, take 30% of the material; zirconia powder, take 5% of the material and mix.

Embodiment 2

[0014] Embodiment 2: It is formed by mixing silicon carbide powder, taking 80% of the material; pure quartz powder, taking 20% of the material.

Embodiment 3

[0015] Embodiment 3: using silicon carbide powder, taking 75% of the material; pure quartz powder, taking 17% of the material; titanium oxide powder, taking 8% of the material and mixing.

[0016] Significant effect of the present invention is described in detail as follows;

[0017] Mix the three raw materials in the above Example 1 evenly, coat the infrared quartz lamp tube of the self-made tungsten halogen lamp (filament working temperature is close to 2260-2400K) with ethyl cellulose ethanol and acetone solution, and melt it on The wall of the lamp tube is coated.

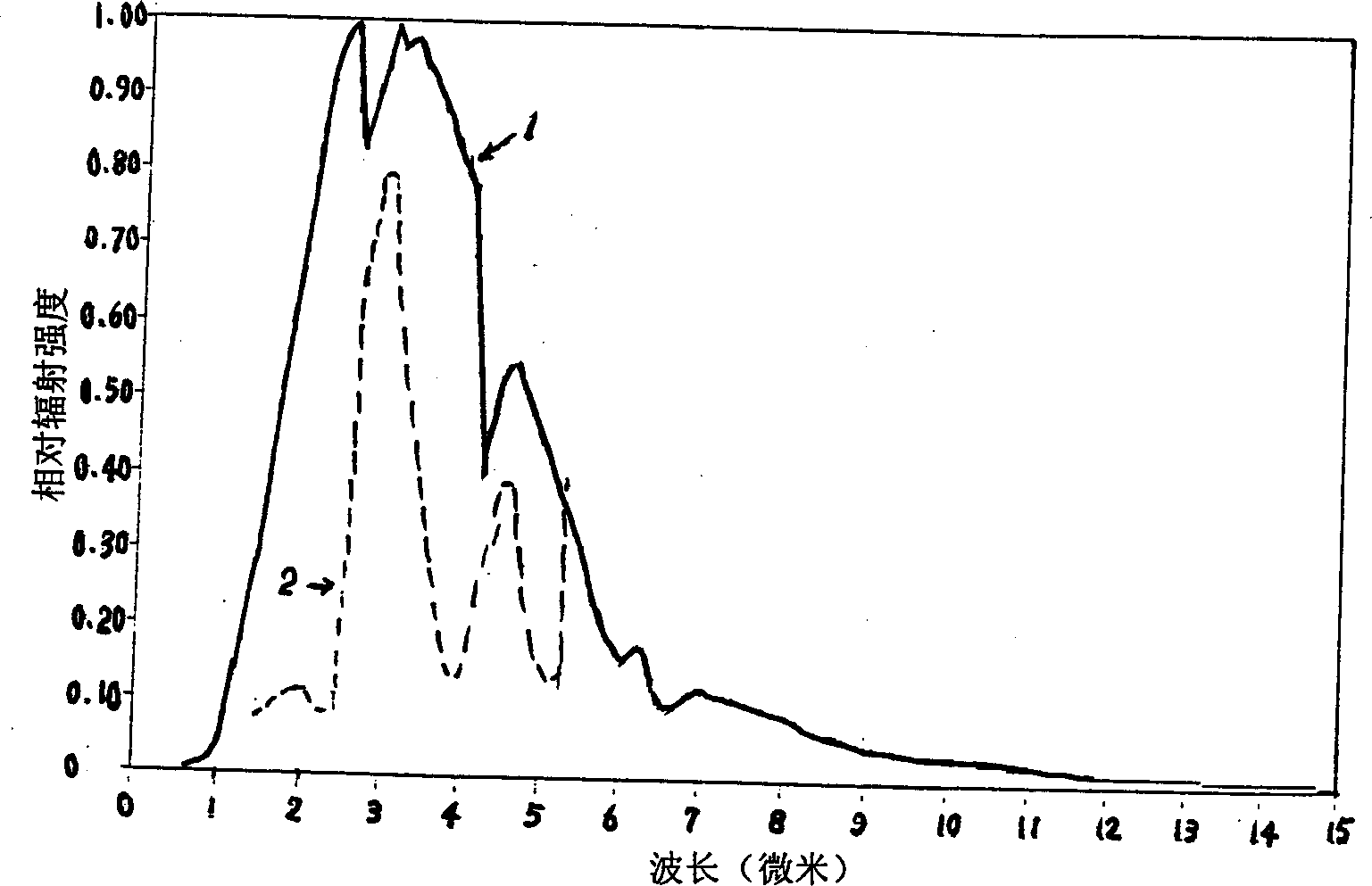

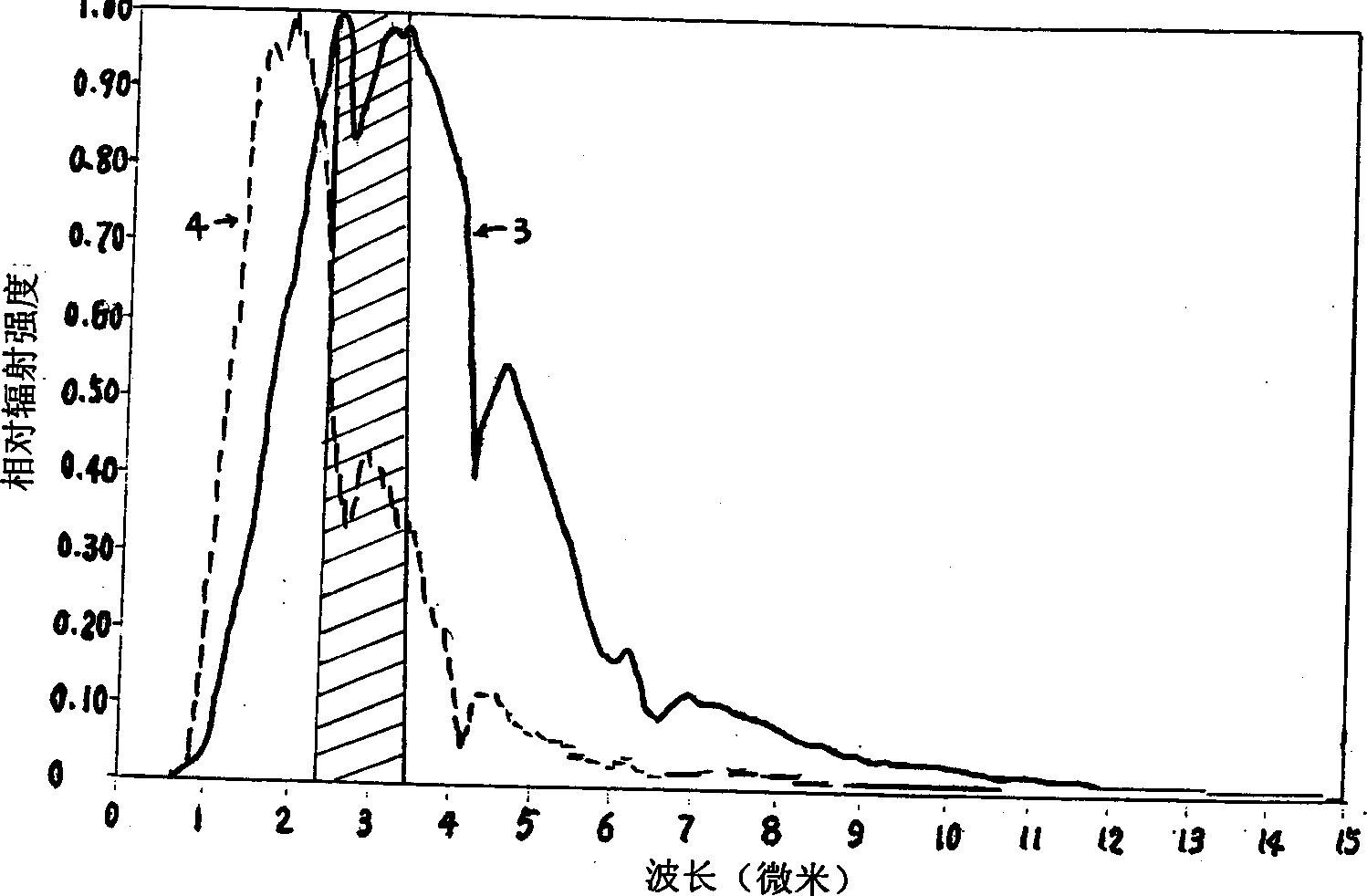

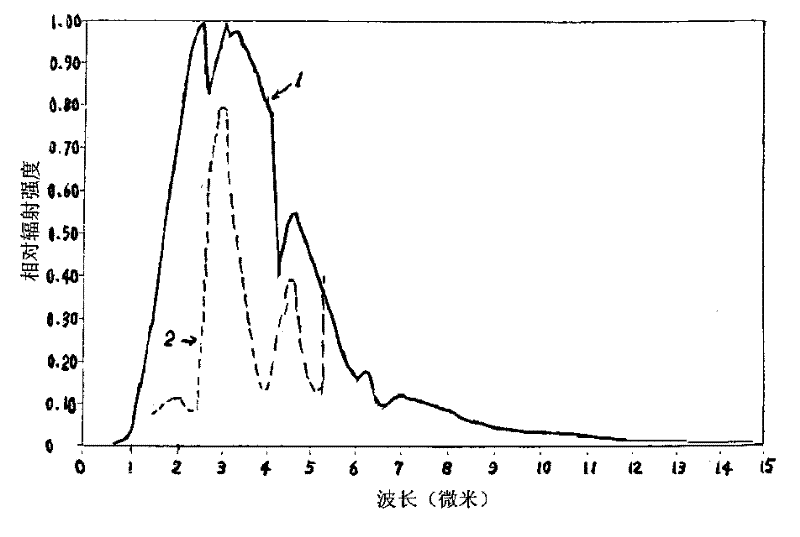

[0018] When the test temperature is 45°C, the emissivity of the short wave between 2.4 microns and 3.4 microns reaches 0.97. Tests and experiments show that the design of this coating can effectively transfer the visible light and near-infrared radiation of tungsten wires with different voltages. to the mid-infrared region, so that the peak wavelength of the radiation appears at 3 microns from the infrared abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com