Method and system of controlling taper growth in a semiconductor crystal growth process

A crystal growth and semiconductor technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problem of not providing the repeatability of cone growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

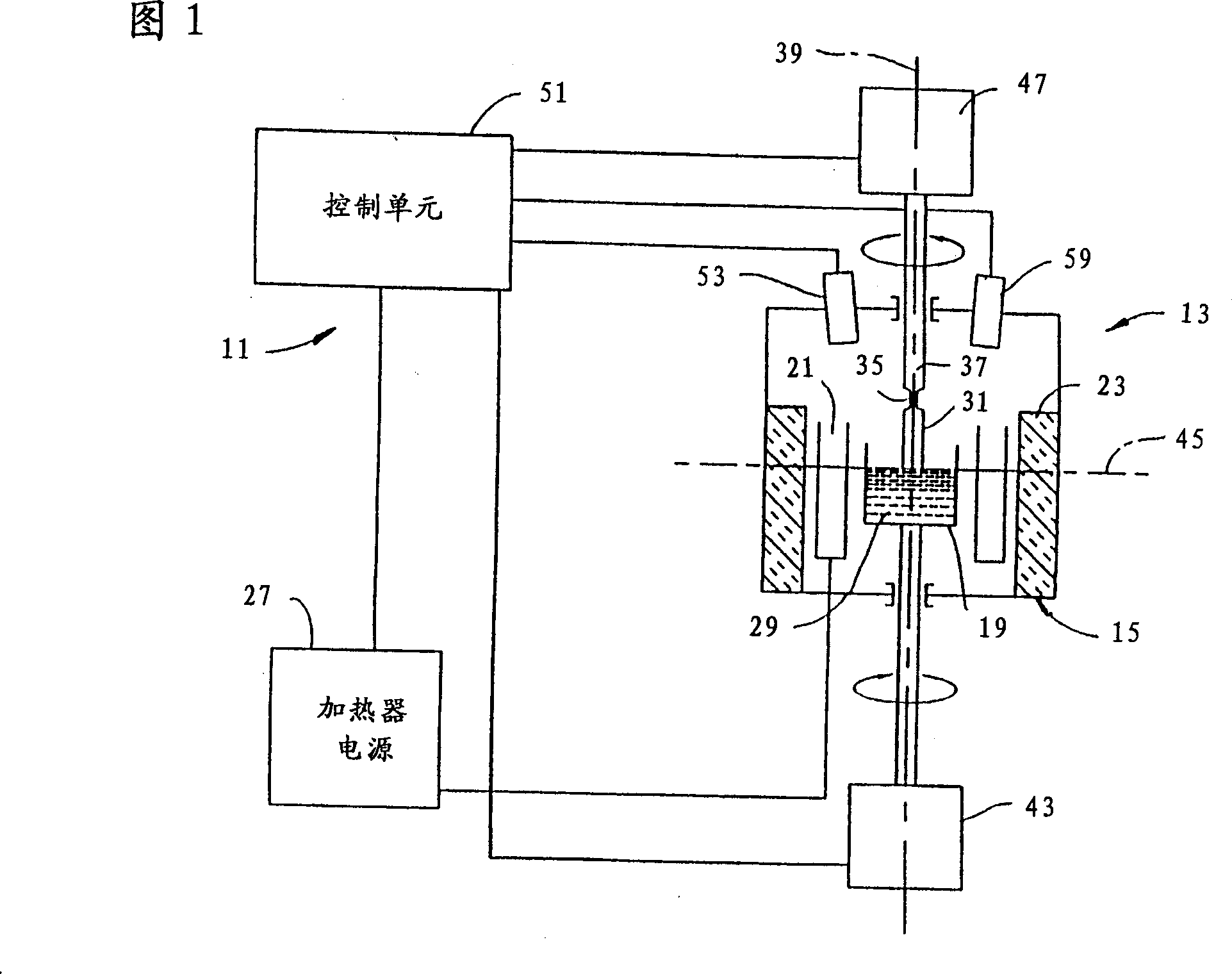

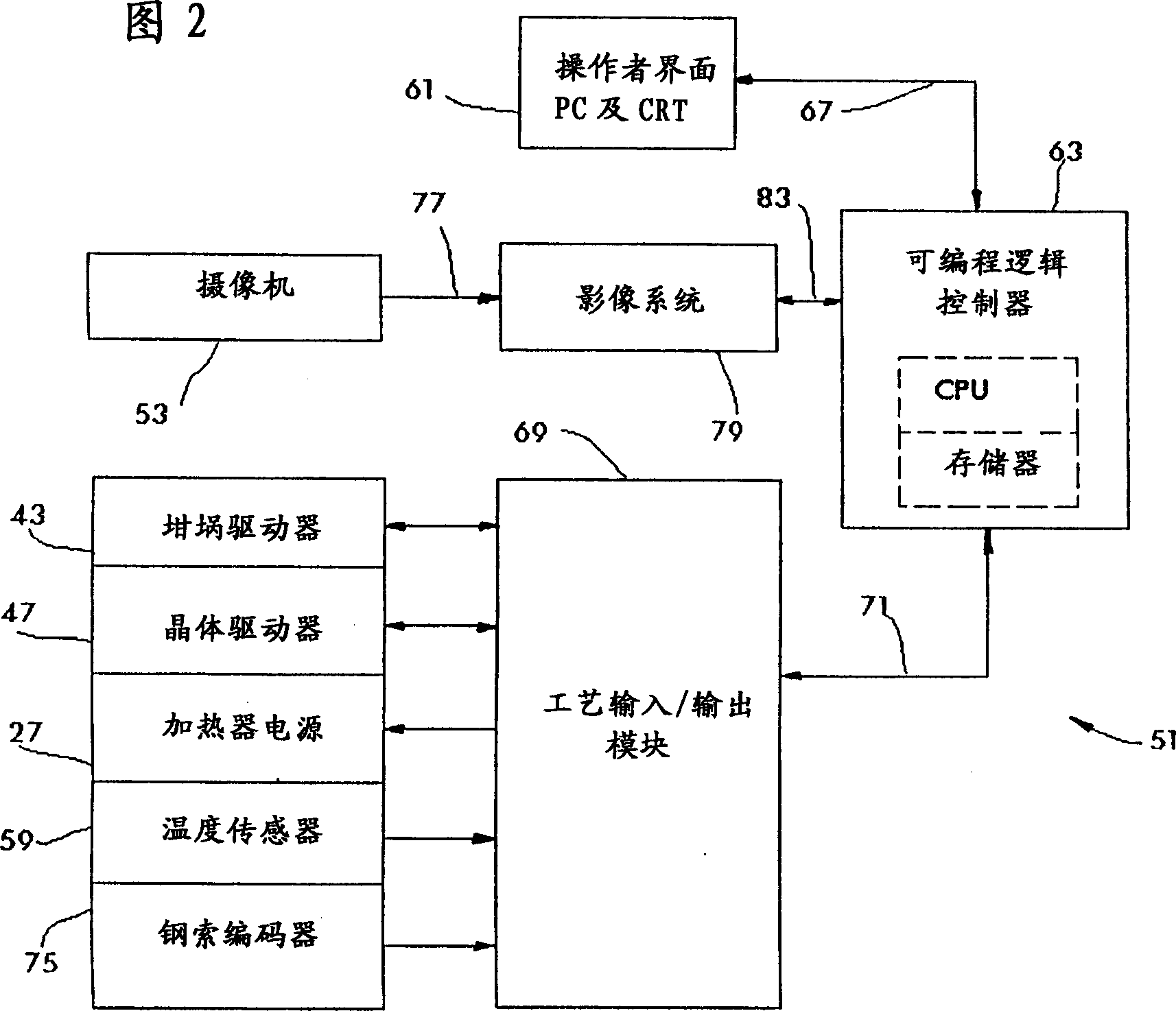

[0021] Referring now to system 11 shown in FIG. 1 for use with Czochralski crystal growth apparatus 13 . The detailed construction of crystal growth equipment is well known to those of ordinary skill in the art. In general, crystal growth apparatus 13 includes a vacuum chamber 15 containing a crucible 19 . A heating device such as a resistance heater 21 surrounds the crucible 19 . In one embodiment, insulating material 23 is lined at the inner walls of vacuum chamber 15 around which there is a water-permeable vacuum chamber cooling jacket (not shown). The vacuum pump typically evacuates the gas in the vacuum chamber 15 while argon gas, which is an inert gas, is introduced.

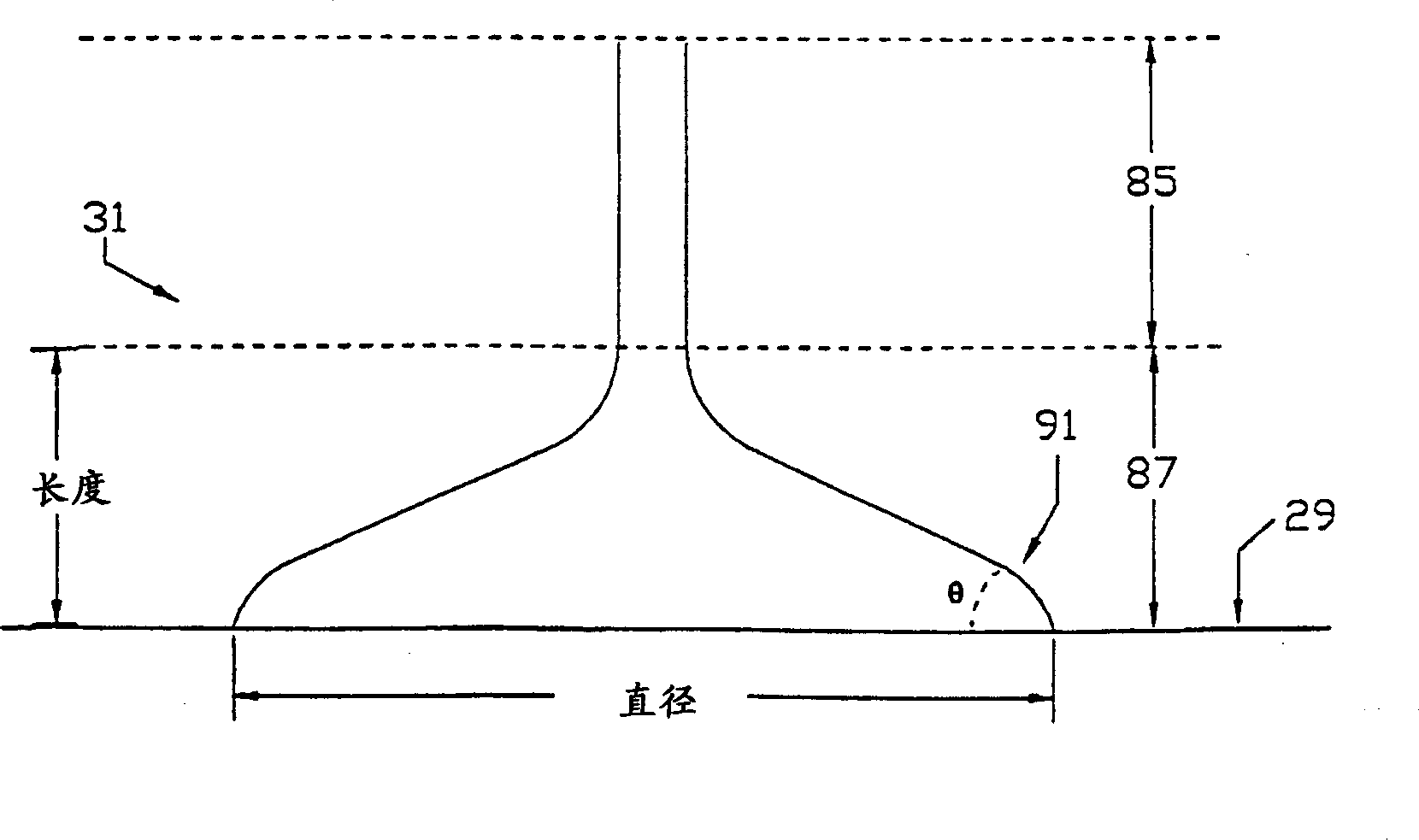

[0022] According to the Czochralski single crystal growth process, the crucible 19 is filled with a certain amount of polysilicon. The heater power supply 27 supplies current through the resistance heater 21 to melt the charged raw material, thereby forming a silicon melt 29 from which a single crystal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com