Cast-in-situ pedestal pile with variable bearing and its construction method

A grouting pile and variable technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of low bearing capacity of cast-in-place piles, large settlement of buildings, small settlement of buildings, etc., and achieve good pile quality. , the effect of saving materials and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings and embodiments.

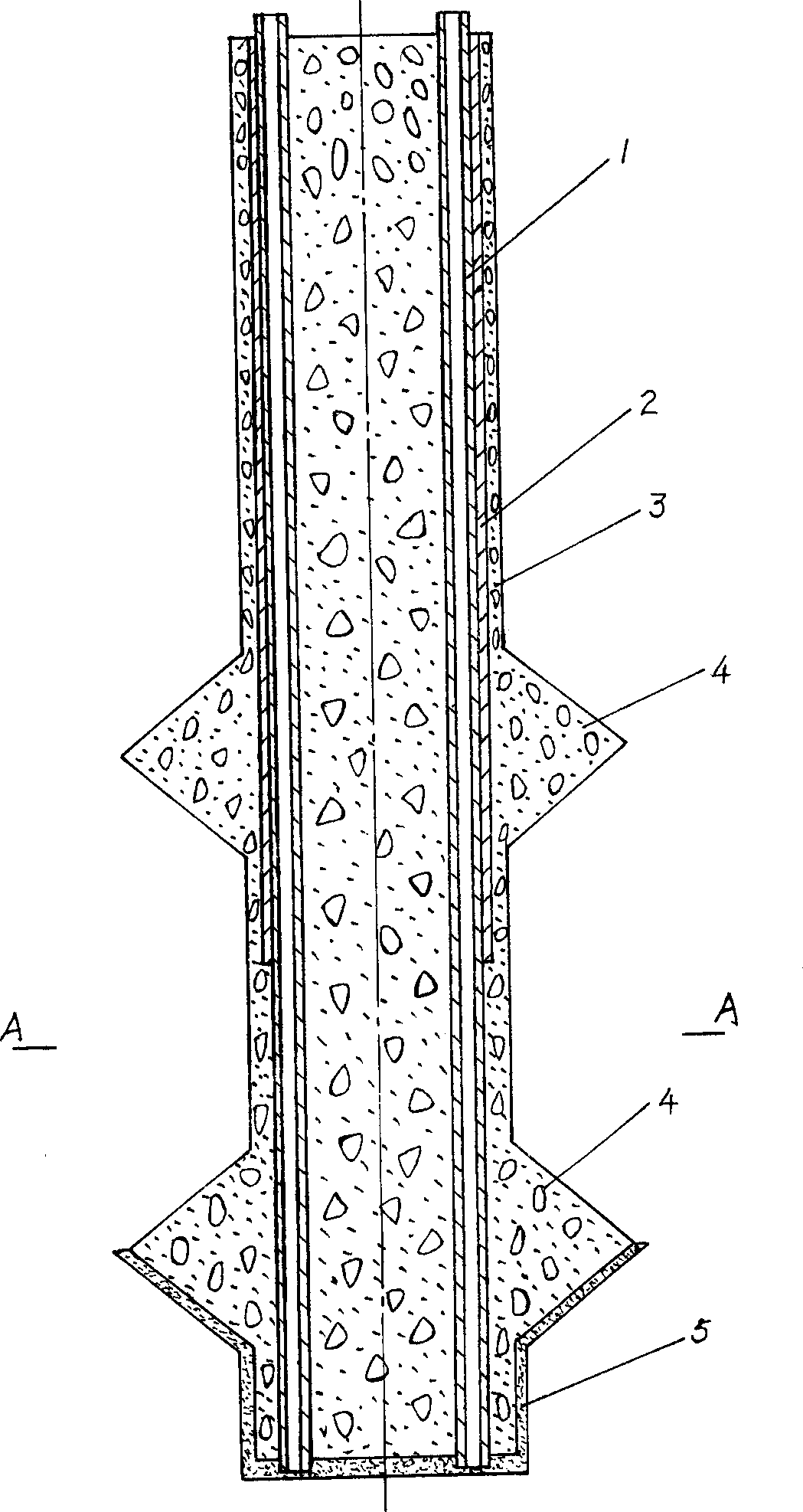

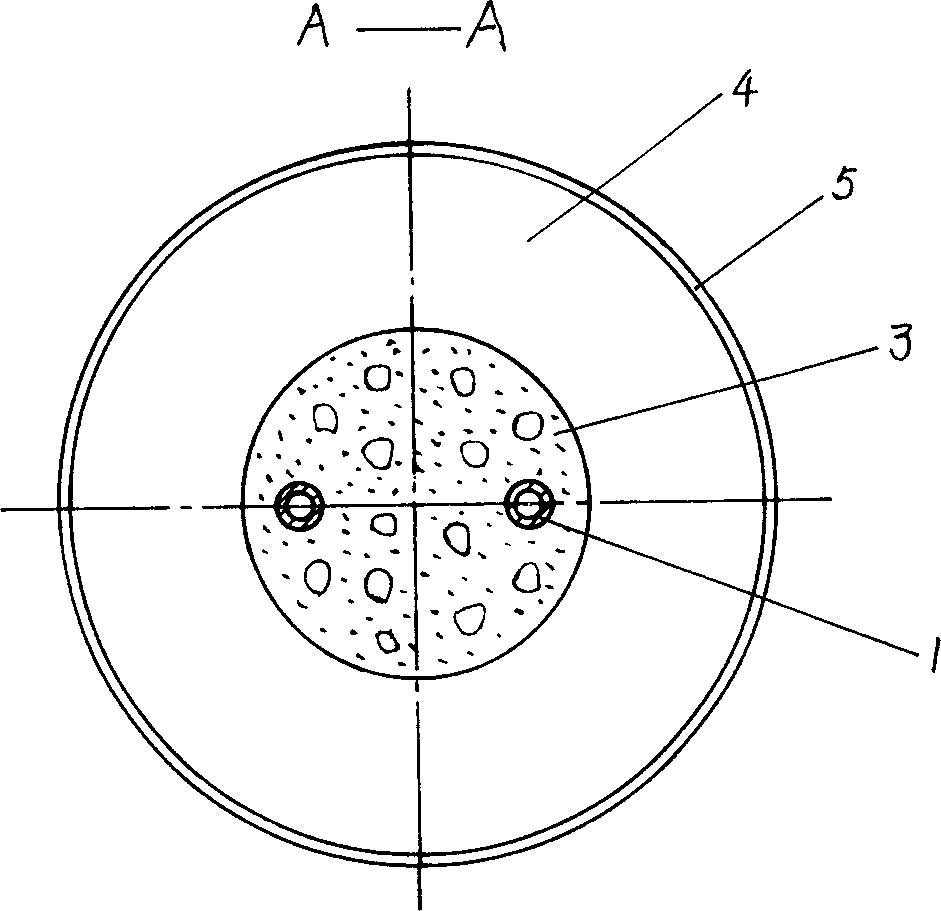

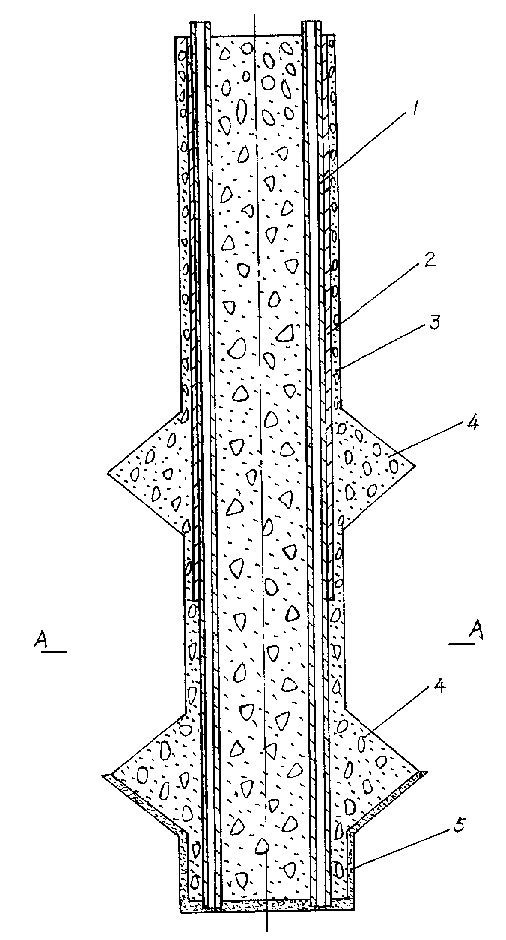

[0016] Such as figure 1 with figure 2 As shown, the variable bottom-expanded branch-plate grouting pile in this embodiment includes a steel cage 2, a concrete pile column 3, a grouting pipe 1 and two circular-cone-shaped variable branch plates 4, Among them: it also includes cement 5; the grouting pipe 1 is tied to the steel cage 2, and the steel cage 2 is set in the concrete pile 3, so that the grouting port of the grouting pipe 1 extends out of the top surface of the concrete pile 3. The grouting port of the grouting pipe 1 extends beyond the bottom surface of the concrete pile 3 to facilitate the injection of grout at the bottom of the pile; two variable support plates 4 are respectively arranged at the bottom of the concrete pile 3 and the middle of the pile The cement slurry 5 is set on the bottom of the concrete pile 3 and the bottom surface of the variable suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com