In-line real-time collinating measurer with computer visulization technique and its calibration method

A technology of computer vision and measuring devices, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of slow speed, low efficiency, inability to manufacture field applications, etc., and achieve the effect of fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

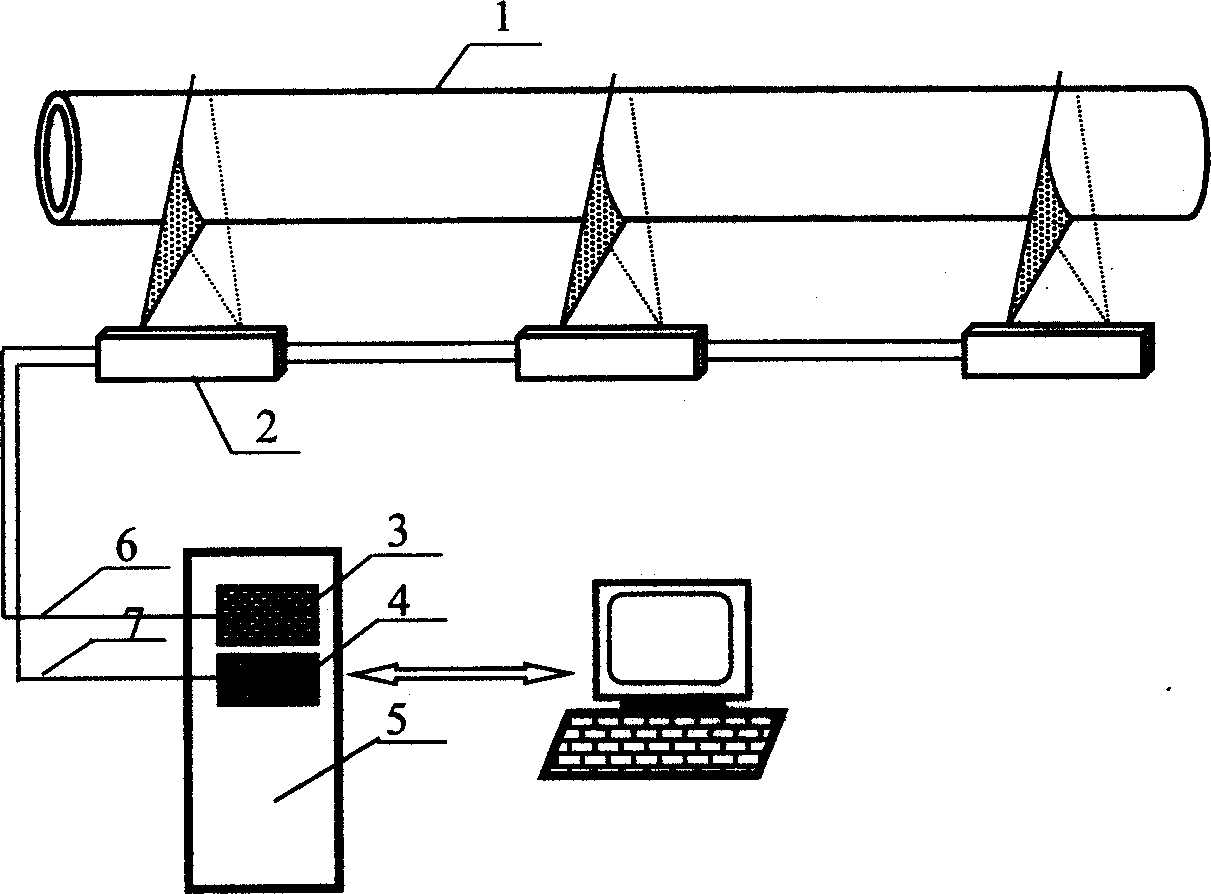

[0015] Such as figure 1 As shown, a complete detection system is composed of multiple visual sensors 2. The number of sensors can be determined according to actual requirements (required range and accuracy). The distance of the steel pipe is about 400mm, and it can also be adjusted according to the diameter of the steel pipe, the working distance of the sensor and other parameters;

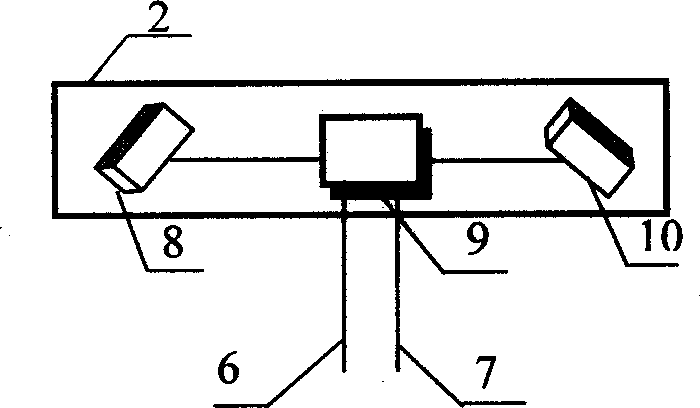

[0016] The sensor is composed of a laser plane projector 8 and a camera 10, and the two form a triangular relationship in space to meet the requirements of the triangulation measurement principle, such as figure 2 shown. When the sensor is measuring, the light plane projector projects a laser plane onto the outer circle of the measured steel pipe to generate a circular arc such as figure 1 , the image comprising the arc is received by the video camera, and the video signal output by the video camera enters the computer 5 through the image acquisition card 3, and the computer analyzes the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com