Method for building up plastic race track

A technology of plastic runway and construction method, applied in the directions of roads, roads, coatings, etc., can solve the problems of difficult to master the spraying time of anti-skid rubber particles, difficult to make the site smooth and beautiful, and unable to directly lay it, so as to achieve a smooth and beautiful site, The effect of increased cost and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

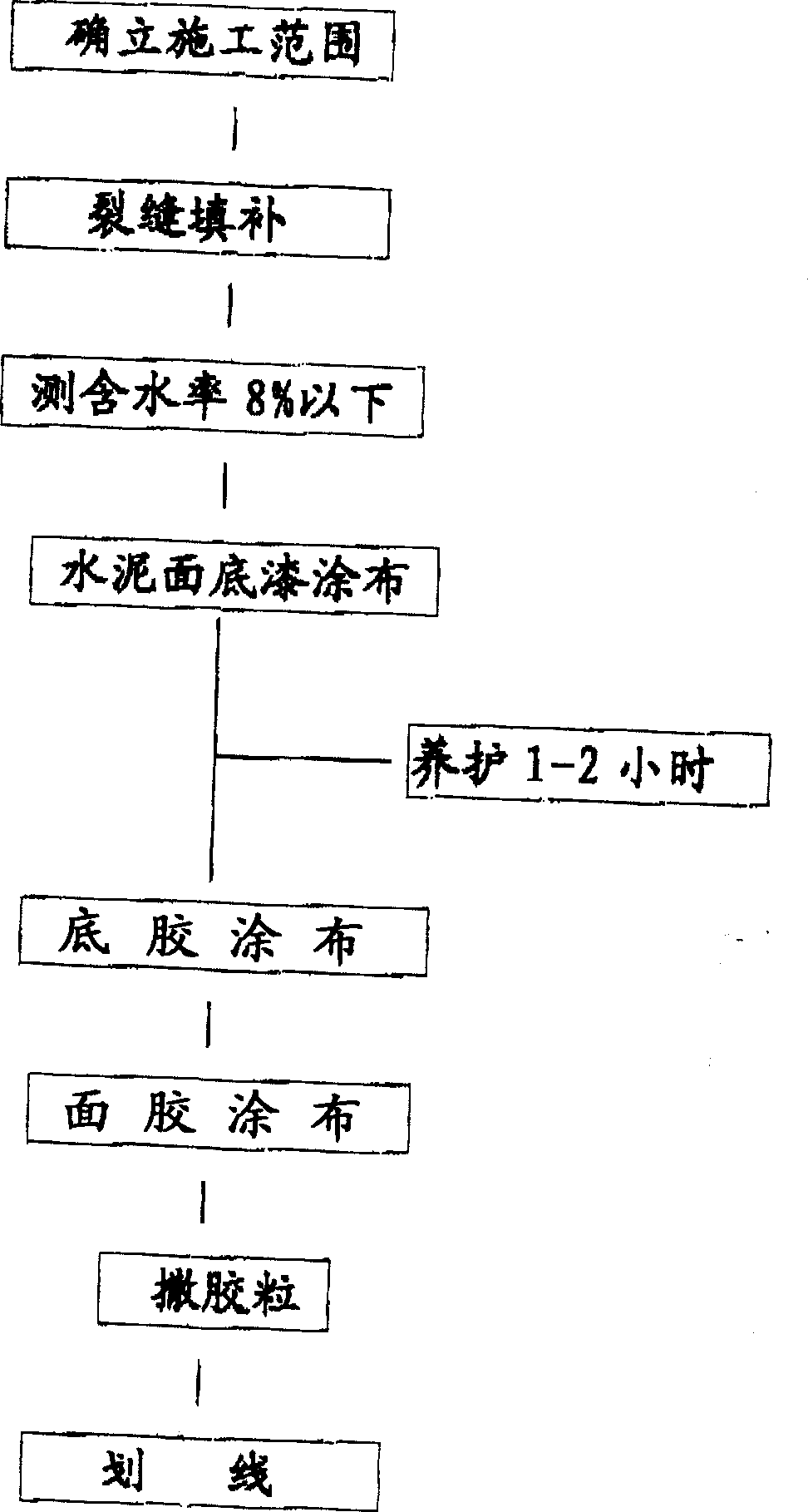

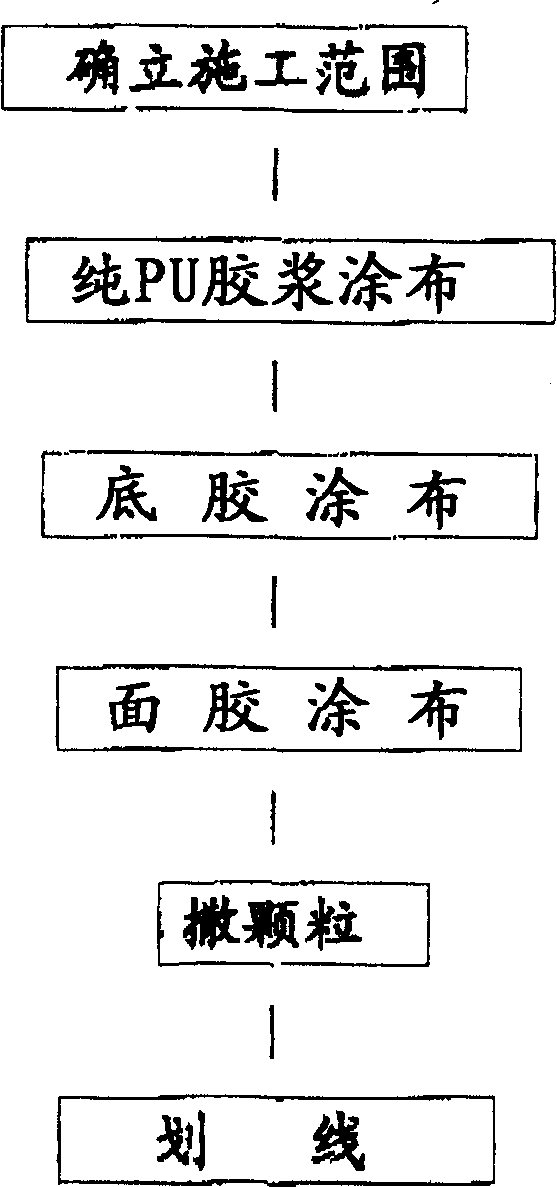

[0022] Please refer to the attached figure 1 , 2 , are schematic diagrams of the construction process of cement-based and asphalt-based plastic runways, respectively. The difference between the two construction methods lies in the first half of the ground repair, maintenance and primer (PU glue) coating process, and the second half of the primer coating, surface glue coating, granulation and scribing processes are basically the same.

[0023] Such as figure 1 As shown, when paving a runway on a cement floor, first establish the construction scope, calculate the paving area and the amount of materials used, and then carry out road surface maintenance such as crack filling. It is necessary to ensure that the dryness of the ground meets the requirements (below moisture content %) If necessary, apply primer and then cure for 1-2 hours.

[0024] Such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com