Engine-adjustable whirlwind generator and method for processing air-inlet hole of adjustable whirlwind generator

一种发生装置、加工方法的技术,应用在发动机元件、发动机控制、燃烧发动机等方向,能够解决流动气流流速降低等问题,达到减少空气气流阻力、制造成本不高、结构简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. In the following description and drawings, the same numerals are used on the same or similar components, so the description of the same or similar components will be omitted.

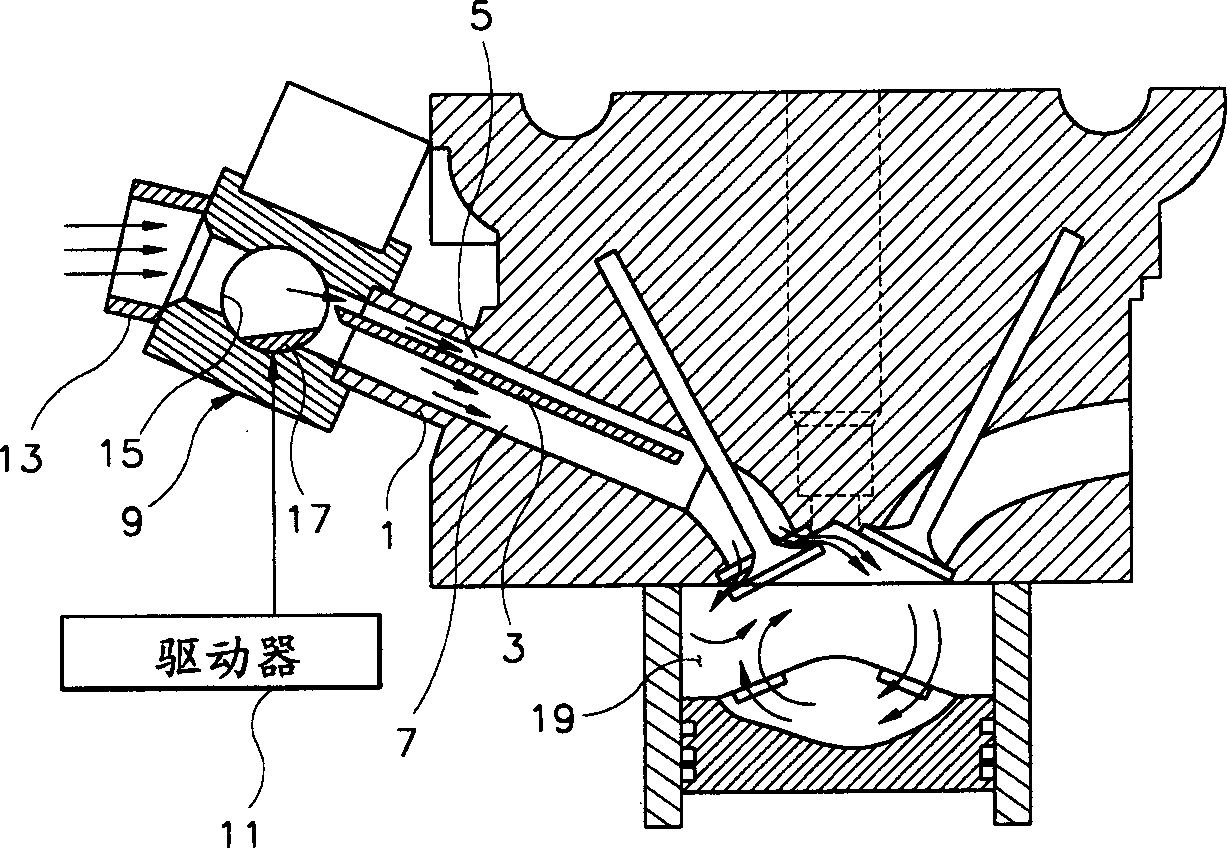

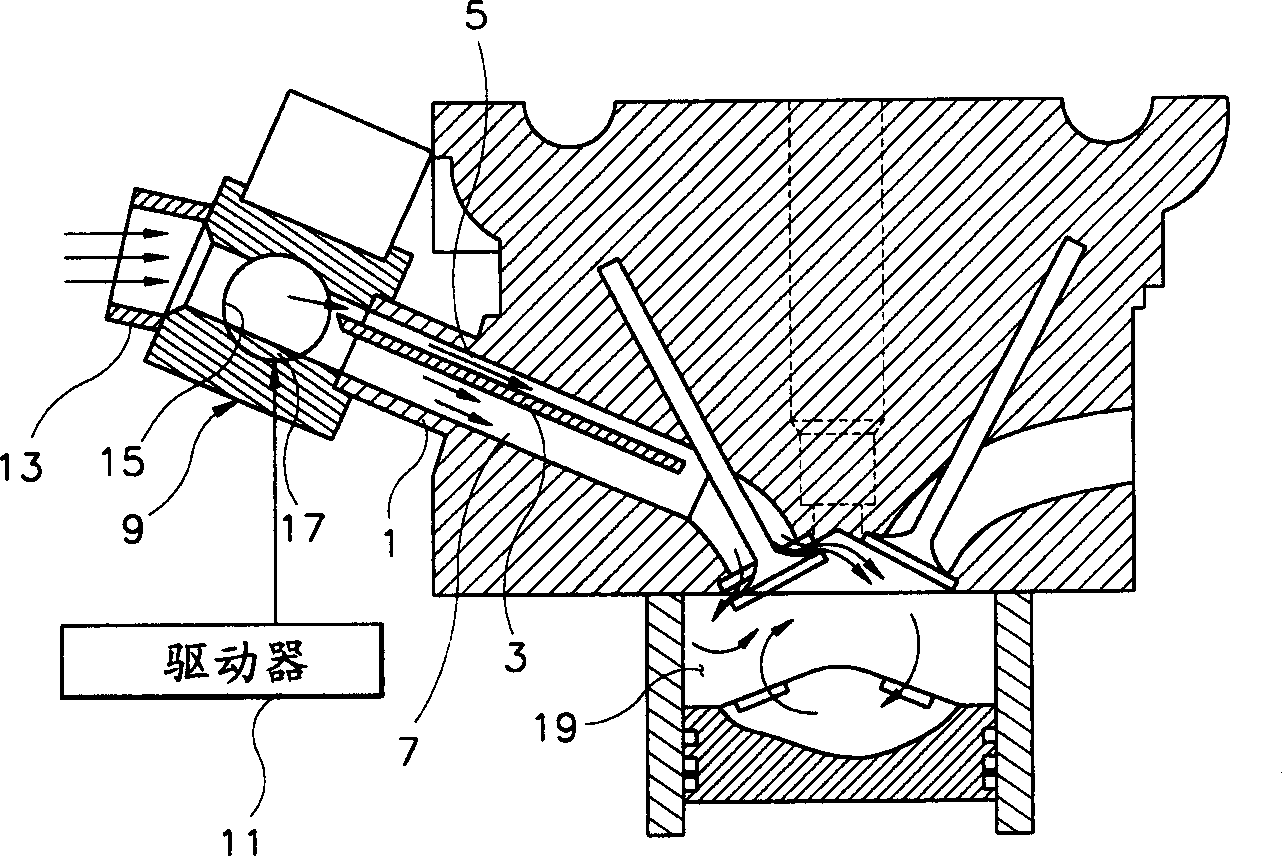

[0025] According to the present invention, figure 2 A variable swirl generating device for an engine is shown. Such as figure 2 As shown, the air inlet 1 includes a partition 3 for dividing the air inlet 3 into a first channel 5 and a second channel 7 through which air flows. At the air inlet end of the partition 3, an opening control valve 9 is installed for selectively changing the opening degree of the first passage 5 and the second passage 7. The opening degree control valve 9 is connected to a driver 11 for actuating and controlling the valve 9 . The control valve 9 between the intake pump 13 and the intake port 1 has a communication space 15 . In the communication spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com