Indentor and method for producing the same

A technology of indenter and thin film, applied in the direction of testing material hardness, strength characteristics, electrical/magnetic roughness/irregularity measurement, etc., can solve problems such as complex methods and only suitable for brittle materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

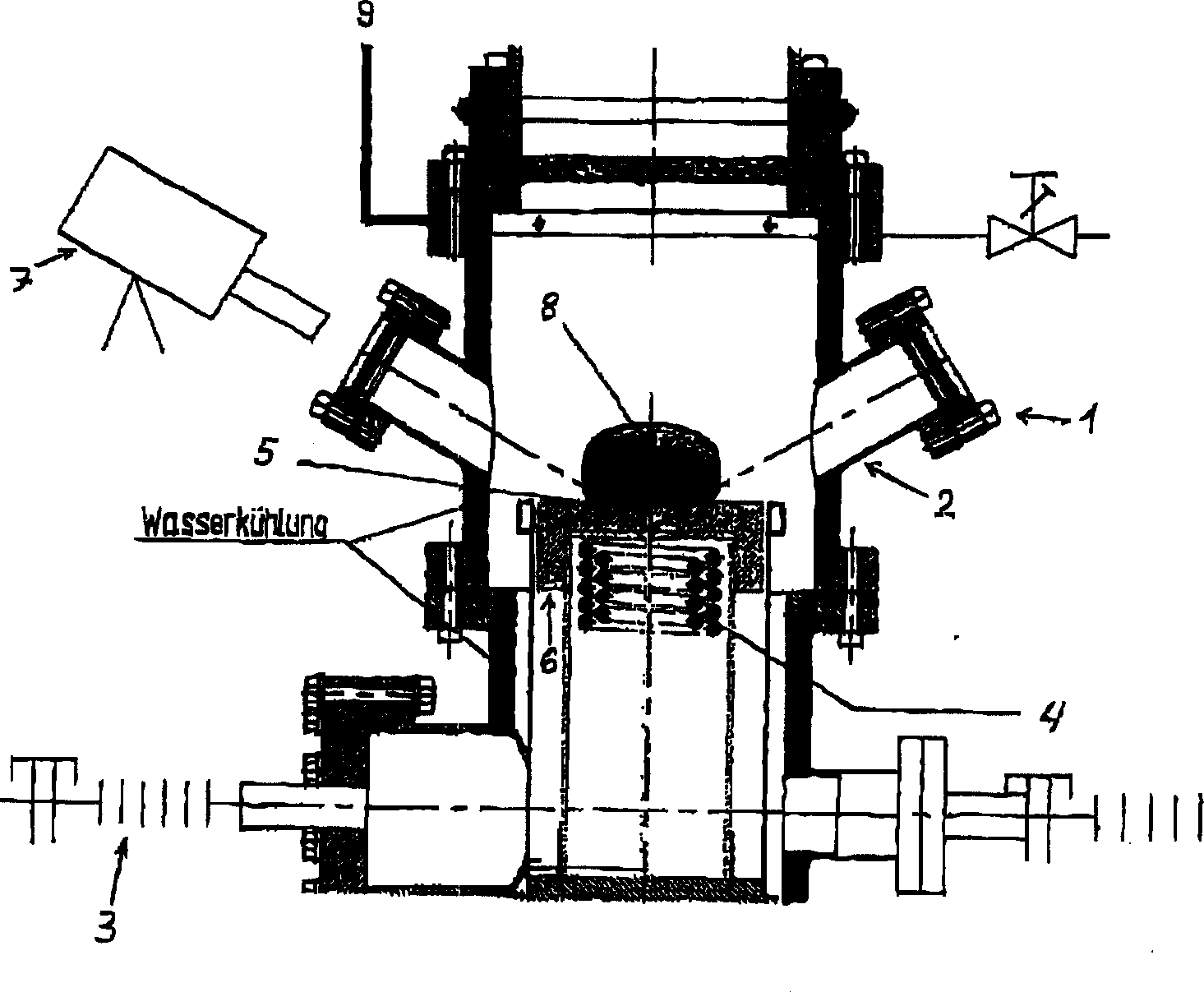

[0021] figure 1 A reaction device 1 for plasma-enhanced chemical vapor deposition is given. The reactor consists of a stainless steel reaction chamber 2 and a microwave generator 3 . Microwave power is adjustable up to 1.5 kW. The high-frequency induction heating system 4 is used to heat the diamond indenter placed directly on the molybdenum plate sample stage. Diamond indenters are commercially available.

[0022] The above-mentioned molybdenum plate 5 is directly placed flat on the graphite heating table 6 . Such a heating table is described in German patent DE19905980A1. By adjusting the temperature of the graphite heating stage, the basic temperature of the sample can be continuously controlled in the range of 200K-1100K. The surface temperature of the sample substrate can be directly measured by a thermometer 7 .

[0023] After the substrate is placed in the reaction chamber, the reaction chamber is evacuated to 10Pa to 30Pa. Substrate 1 is then heated to 600 to 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com