Automatic cigarette processing machine

A technology for machines and cigarettes, applied in the directions of packaging cigarettes, packaging automatic control, instruments, etc., can solve the problems of machine and operator safety hazards and difficult operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

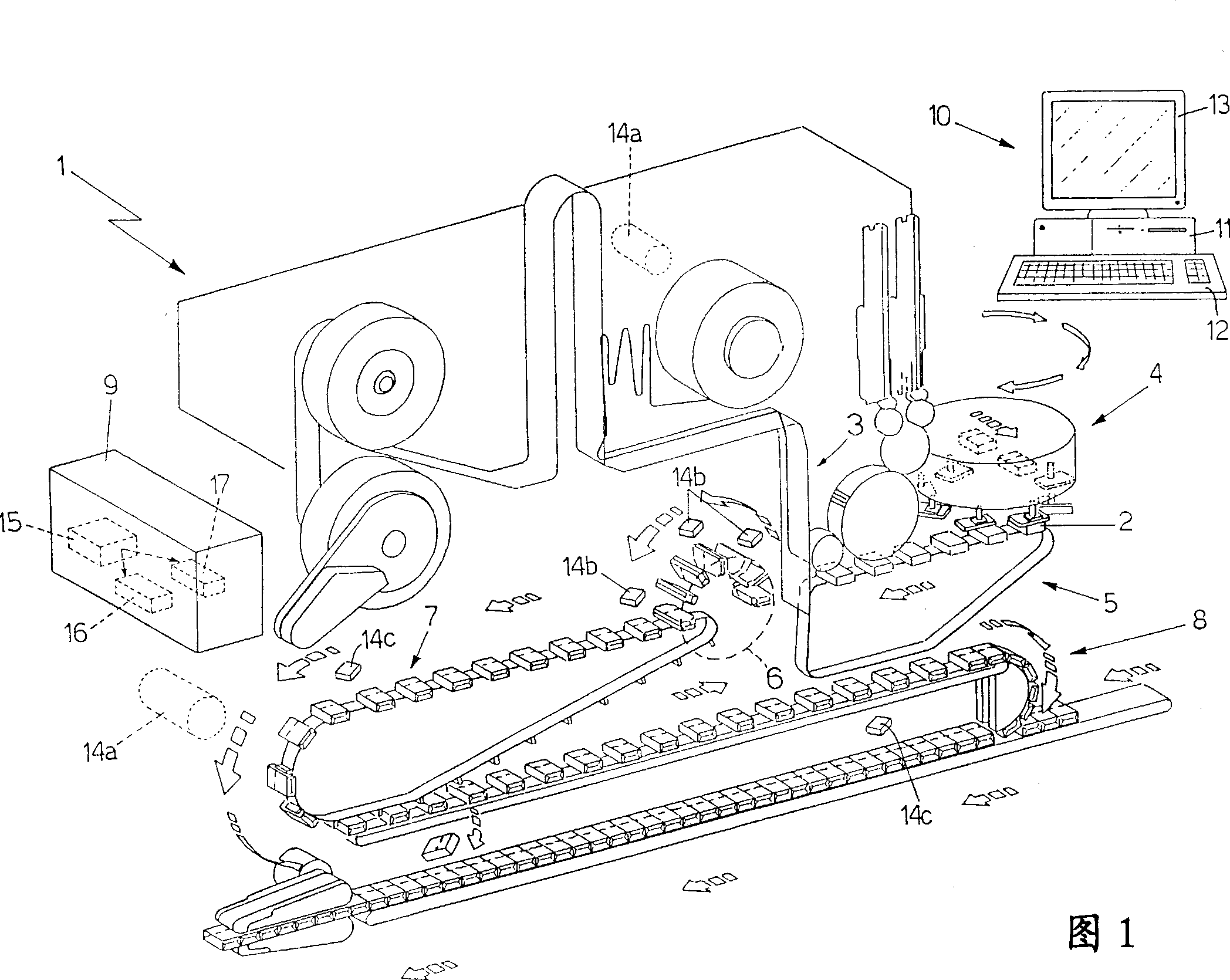

[0012] Numeral 1 in Fig. 1 indicates the whole of a prior art automated machine for wrapping cigarette packs 2 in a strip 3 of plastic transparent material (in particular a "C800" machine manufactured by the company G.D.) .

[0013] The machine 1 comprises an input conveyor 4 for feeding the packs of cigarettes 2 onto a belt conveyor 5 which feeds the packs 2 together with the rod 3 onto a wrapping wheel 6 where There the packaging tube is formed and its edges are heat-sealed around the respective pack 2 of cigarettes, thereby stabilizing it. From the wheels 6 the tubes are transported to a belt conveyor 7 which conveys the tubes along a path while the final folding of the web 3 is carried out around the packs 2 of cigarettes and heat sealed by heat sealing the tubes. The ends stabilize the strip 3. From the belt conveyor 7, the cigarette packs 2 wrapped in respective rods 3 are conveyed onto a drying conveyor 8 for feeding to an automated carton machine (not shown in FIG. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com