Magnetic and gravitational separation and comprehensive utilization of vonsenite

A technology of boron iron ore and boron iron concentrate, which is applied in the field of comprehensive utilization of boron iron ore magnetic-gravity separation separation, can solve the problems of unavailable supply, and achieve the effects of high utilization value, loose roasting conditions and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

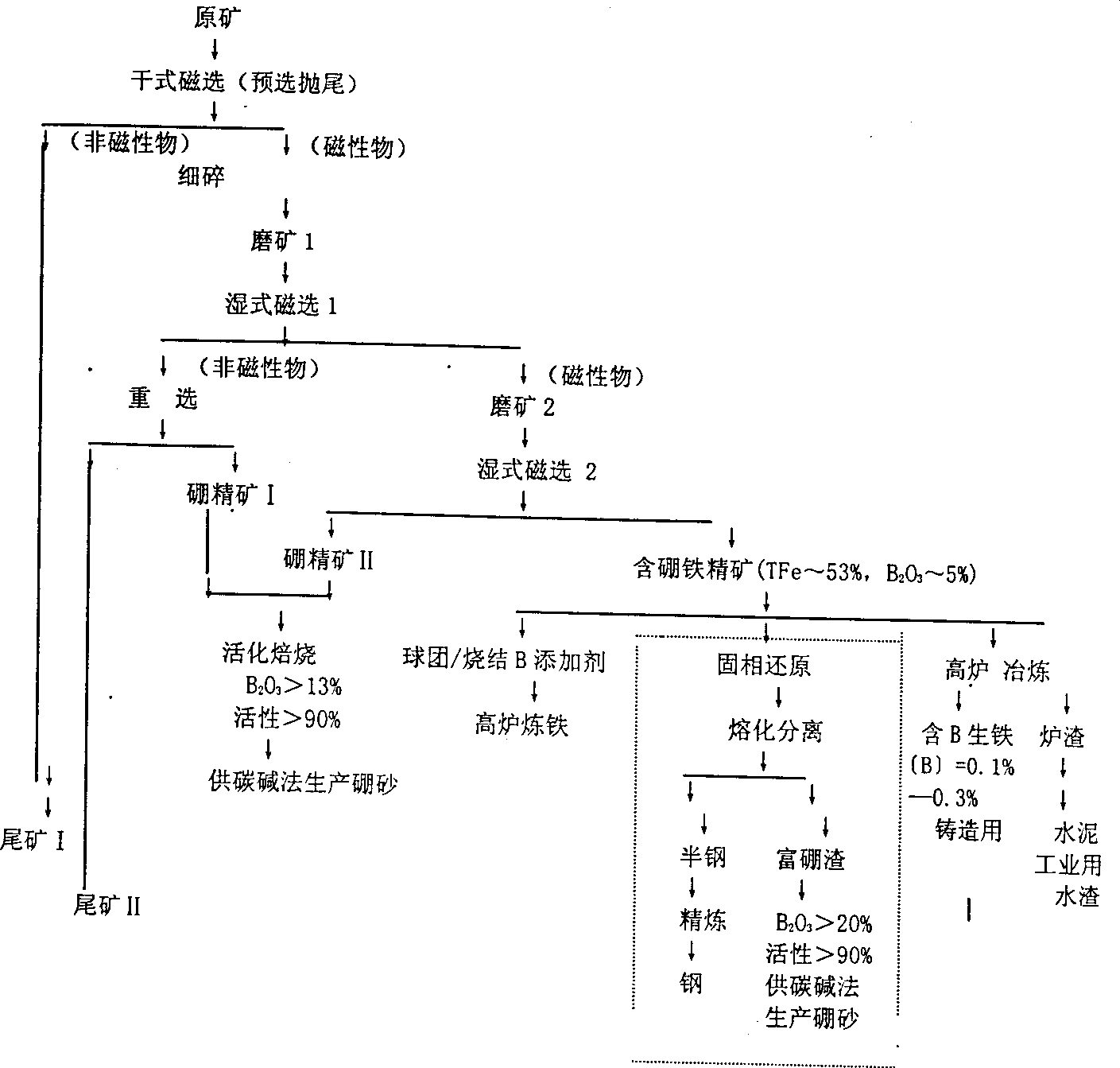

[0017] as the picture shows:

[0018] The raw ore is crushed to less than 20-30mm, and the non-magnetic gangue is removed by magnetic separation. After pre-selection and fine crushing of the tailings, the ore is ground to -0.074mm by grinding 1, accounting for 35-50%. The pulp is separated into magnetic part and non-magnetic part by wet magnetic separation 1 (weak magnetic field strength magnetic separation). In the magnetic part, the ore is ground to -0.074mm by more than 90% through grinding 2, and the high-grade boron concentrate and iron concentrate are separated by wet magnetic separation 2 (magnetic separation with strong magnetic field strength).

[0019] The non-magnetic part uses a water gravity separator to separate the boron concentrate and gangue with boronite as the main mineral.

[0020] The boron concentrates in the beneficiation are combined into one boron concentrate, and the boron concentrate can be directly used to produce borax by the carbon-alkali method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com