Process for industrially preparing acicular coke from coal

A needle coke and coal-based technology, applied in the field of coking and chemical industry, can solve the problems of slagging in the kettle, blockage of pipes, insufficient heat supply, etc., achieve uniform reaction and avoid blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

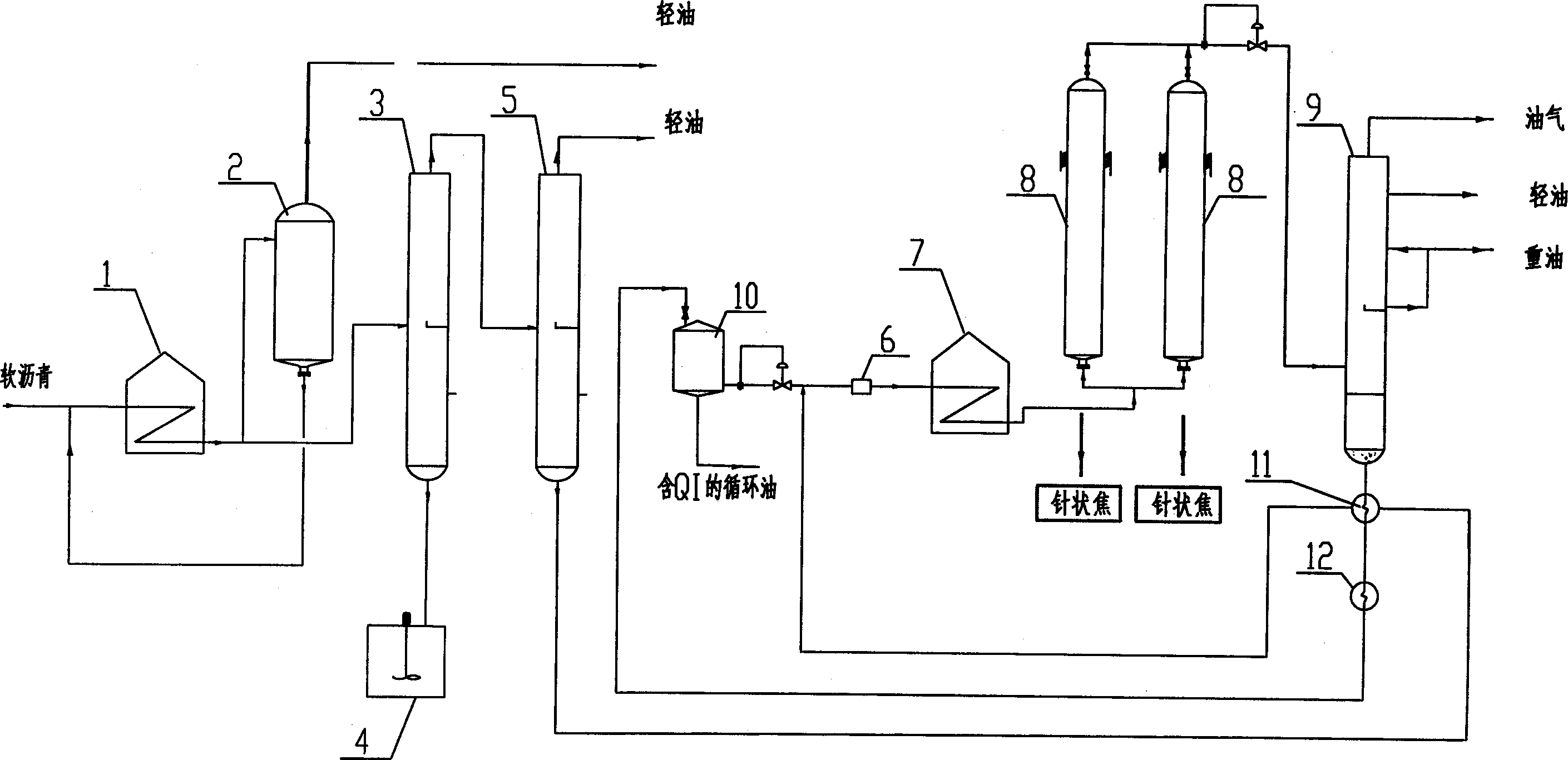

Method used

Image

Examples

Embodiment

[0020] According to the above industrial production process of coal-based needle coke, the raw materials and product quality are as follows:

[0021] Soft asphalt: softening point (SP) 30°C, ash content (A) 0.05%, quinoline content (QI) 4%, benzene content (BI) 8.5%, sulfur content (S) 0.05%

[0022] this invention

(Ansteel Raw Material)

this invention

(Baosteel Raw Materials)

Mitsubishi Corporation

Volatile matter (V)

<0.5%

<0.5%

0.56

True specific gravity: (d)

2.13

2.12

2.12

Resistivity (ρ)

10 -6 Ωmm 2 / m

5

6.5

5.5

Thermal expansion coefficient

(CTE)×10 -6 / °C

0.99

1.56

1.0

[0023] Explanation: V and d are the measured values after calcining the pointer coke, and ρ and CTE are the measured values after graphitization of the specimen.

[0024] CTE is a measured value at 100-600°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com