Method for preparing plasticized flexible high-brightness nano projection display screen material

A high-brightness, nano-technology, applied in the field of screen display, can solve the problems of inconvenient practical application, poor plasticity of the display screen, easy to break, etc., and achieve the effect of strong consistency, high contrast, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

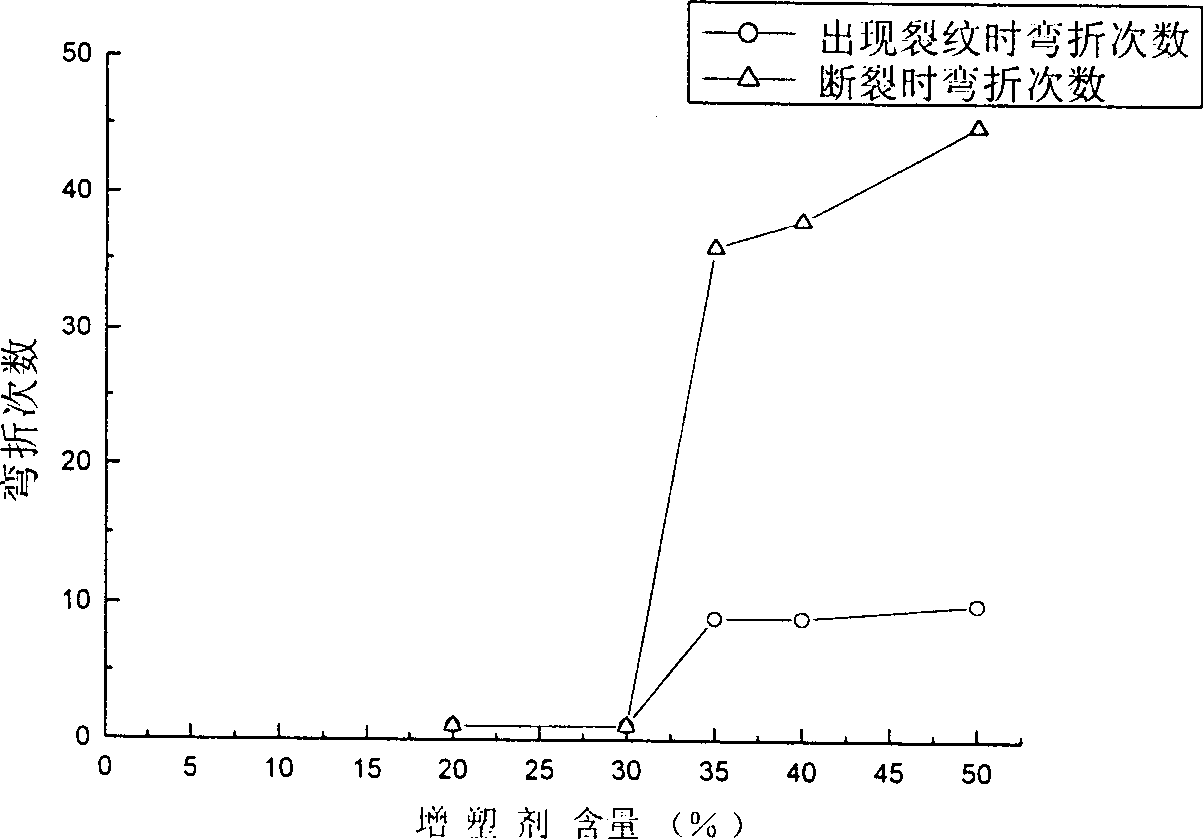

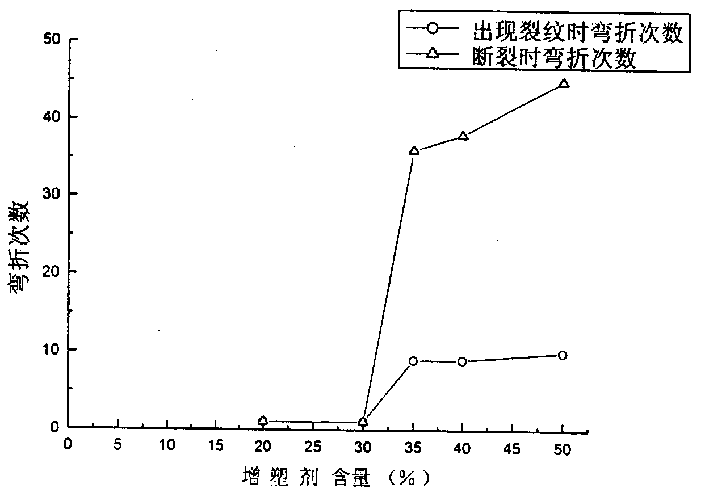

Image

Examples

Embodiment 1

[0020] Main material methyl methacrylate 66%, plasticizer butyl acrylate 32%, brightener non-polar SiO 2 Nano powder 1.5% and Al 2 o 3 Nano powder 0.35%, initiator azobisisobutyronitrile 0.15%. Methyl methacrylate, SiO 2 Nano powder, Al 2 o 3 Mix the nano-powder and stir until uniform; add the plasticizer butyl acrylate, the initiator azobisisobutyronitrile at 75°C, and add a small amount of release agent silicone oil at the same time, stir until uniform, and carry out the first stage of polymerization initiation . Fill the mold and carry out prepolymerization at 45°C for 28 hours. The temperature was raised vigorously to 75° C., and the polymerization was carried out intensively for 2 hours. Cool in the furnace and demould.

Embodiment 2

[0022] Main material methyl methacrylate 66%, plasticizer phthalyl dioctyl 32%, brightener non-polar SiO 2 Nano powder 1.5% and Al 2 o 3 Nano powder 0.35%, initiator azobisisobutyronitrile 0.15%. Methyl methacrylate, SiO 2 Nano powder, Al 2 o 3 Mix the nano-powder and stir until uniform; add the plasticizer o-phthalic dioctyl dioctyl ester, the initiator azobisisobutyronitrile at 75°C, and add a small amount of release agent silicone oil at the same time, stir until uniform, and carry out the second One-stage initiated polymerization. Fill the mold and carry out prepolymerization at 45°C for 28 hours. The temperature was raised vigorously to 75° C., and the polymerization was carried out intensively for 2 hours. Cool in the furnace and demould.

Embodiment 3

[0024] The main material is 66% methyl methacrylate, 32% plasticizer phthalate dibutyl, brightener non-polar SiO 2 Nano powder 1.5% and Al 2 o 3 Nano powder 0.35%, initiator azobisisobutyronitrile 0.15%. Methyl methacrylate, SiO 2 Nano powder, Al 2 o 3 Mix the nano-powder and stir until uniform; add the plasticizer o-phthalylene dibutyl ester, the initiator azobisisobutyronitrile at 75°C, and add a small amount of release agent silicone oil at the same time, stir until uniform, and carry out the second One-stage initiated polymerization. Fill the mold and carry out prepolymerization at 45°C for 28 hours. The temperature was raised vigorously to 75° C., and the polymerization was carried out intensively for 2 hours. Cool in the furnace and demould.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com