Stereo multi-dimensinal multi-mode capillary electrophoresis method and its special equipment

A technology of capillary electrophoresis and special devices, which is applied in the direction of measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problems of relatively harsh instrument conditions, large loss of column efficiency, and limited application, so as to avoid the reduction of column efficiency, The effect of small loss of column efficiency and guaranteed high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Two-dimensional tandem capillary column electrophoresis:

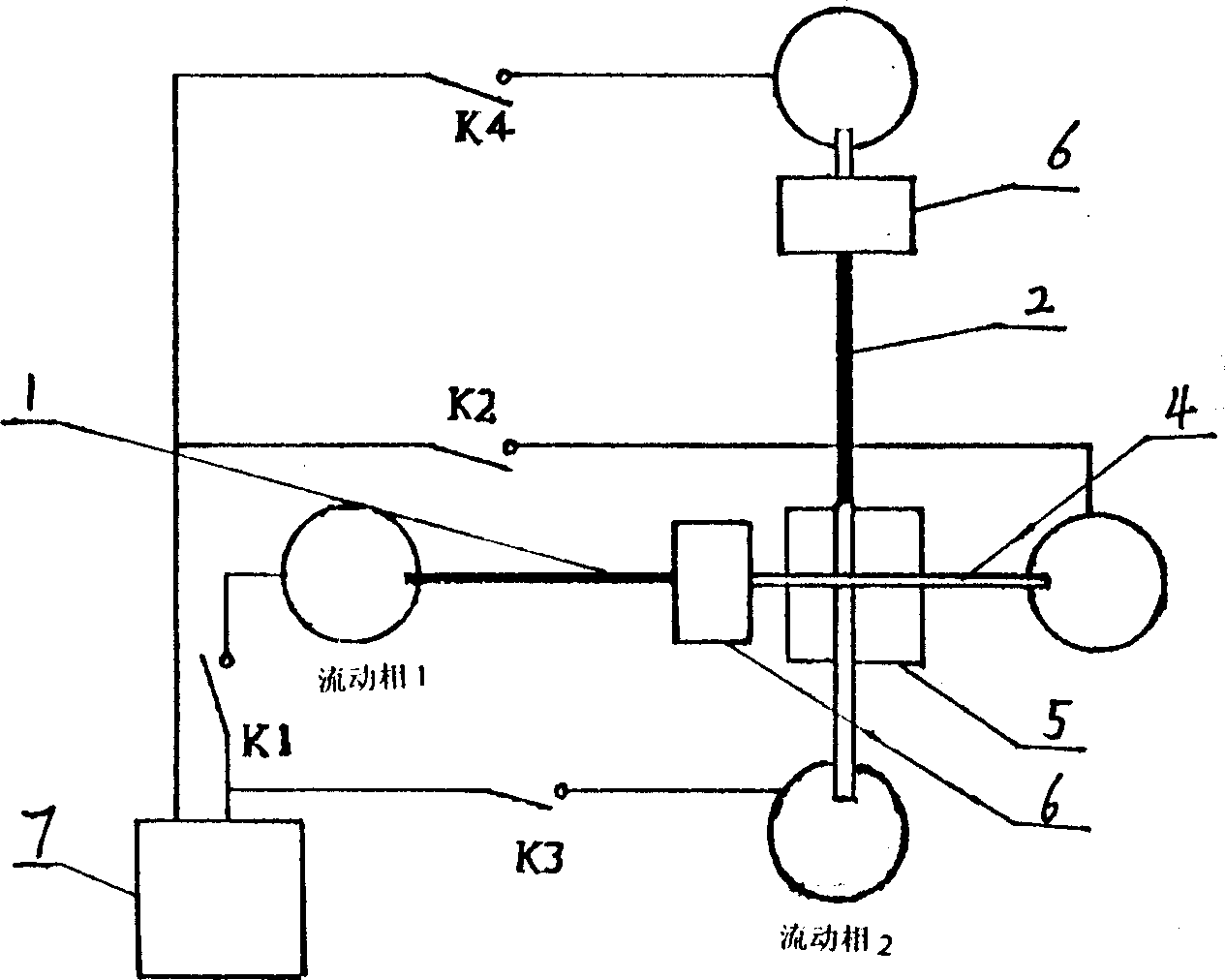

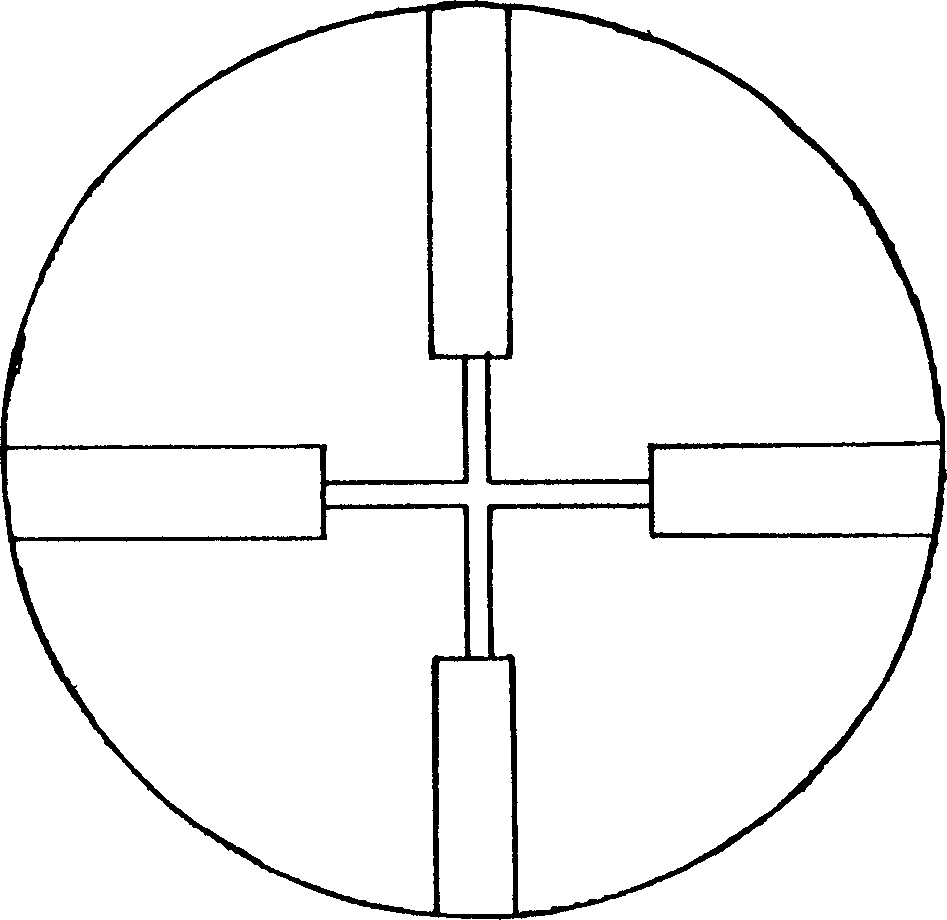

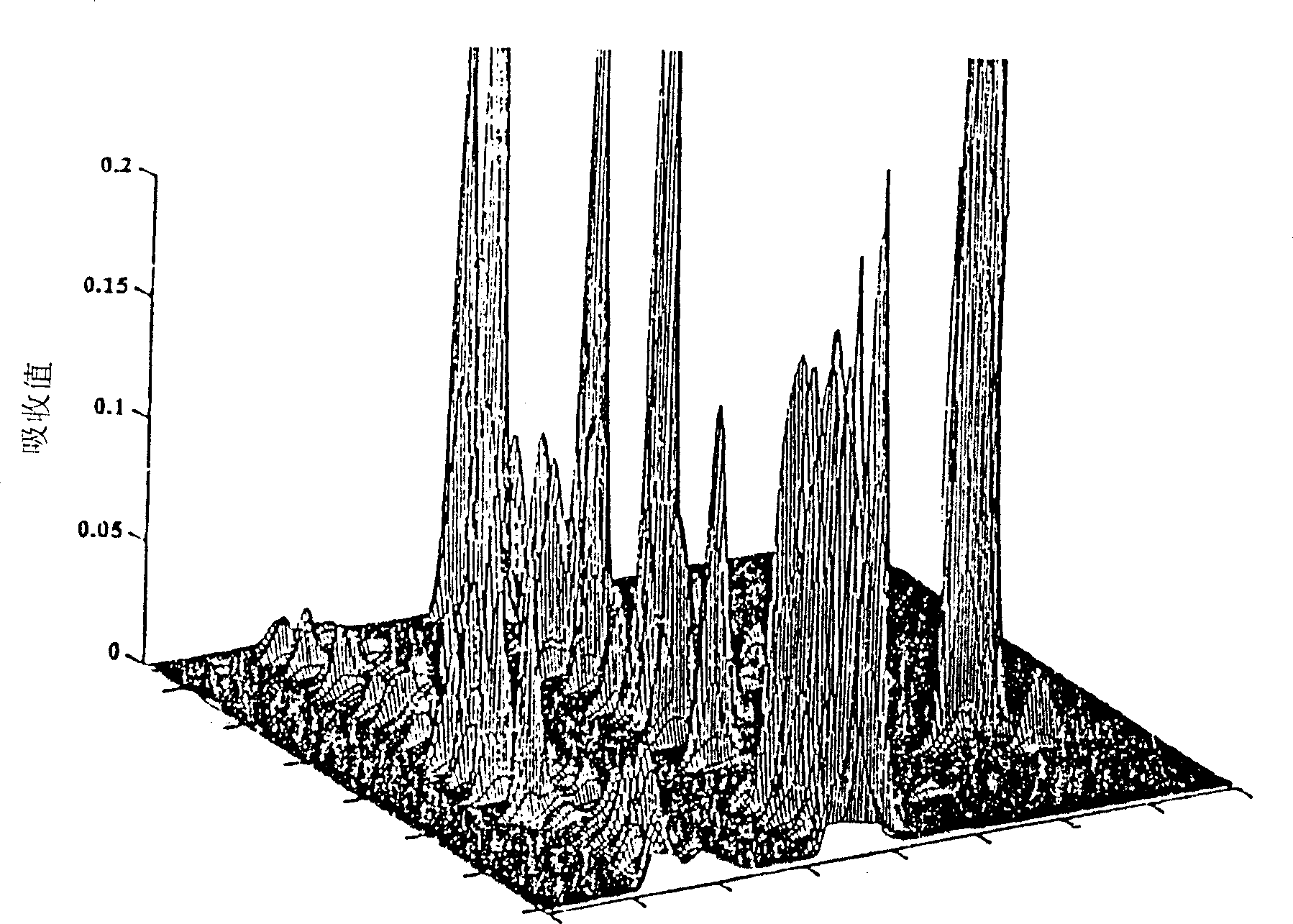

[0024] Such as figure 2 As shown, capillary column A1 adopts capillary gel electrophoresis separation mode, and capillary column B2 adopts capillary electrochromatography or capillary zone electrophoresis separation mode. The required capillary columns A1 and B2 are designed to have the same size, and are respectively inserted into the interface of connector 5, and After adhesive bonding, the connecting piece 5 is a four-way structure, and the hollow capillary 4 is joined at the point-symmetrical position of the connecting piece 5. In order to avoid unnecessary loss of column efficiency, the setting of the capillary columns A1 and B2 connected through the connecting piece 5 , the sample components in the capillary column A1 should not pass through the flow path with a small angle during the process of switching into the capillary column B2, so as to avoid unnecessary peak broadening; As for the window, the det...

Embodiment 2

[0040] The difference from Example 1 is that in this example, the capillary columns A1 and B2 adopt the same separation mode of capillary gel electrophoresis, and the inner diameters of the capillary columns are different, and a matching connector 5 is used. Driven by an electric field, Auxiliary application of appropriate pressure so that the sample does not flow out of the free capillary column port, separation, that is, the overall system has great selectivity adjustment flexibility.

Embodiment 3

[0042] The difference from Example 2 is that the mobile phases of the present invention are different according to the separation mode and the actual separation needs. In addition to considering its compatibility, each mobile phase can be adjusted independently without being affected. When the capillary columns A1 and B2 When the separation mode is the same, the separation results of different mobile phases are similar to the special step gradient elution separation, and the length and height of the steps can be easily changed, which is conducive to the optimization of separation conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com