Device for reducing pressure pulsations in hydraulic manifolds

A pressure pulsation, pressure technology, applied in the direction of pipe elements, fluid flow, springs/shock absorbers, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

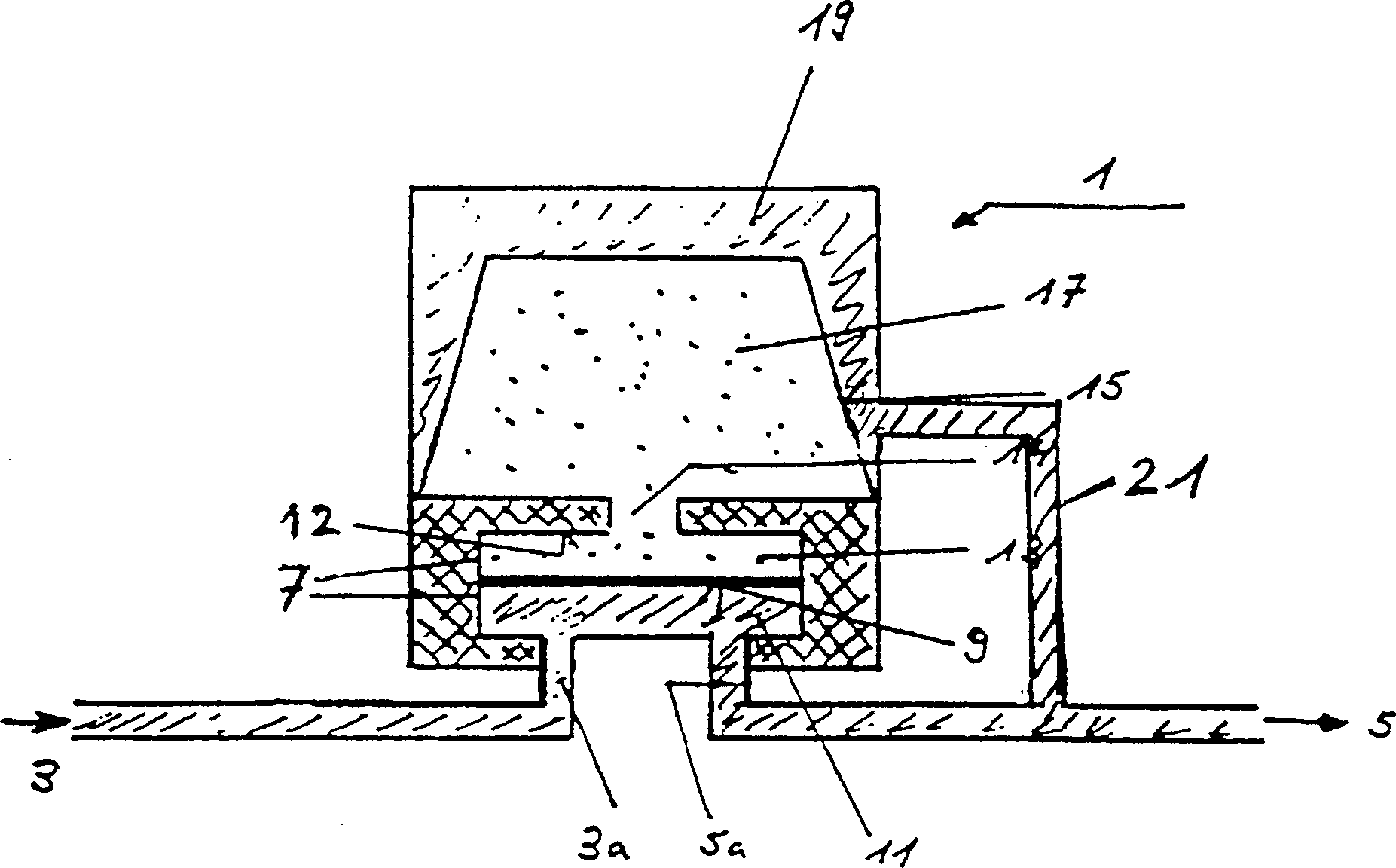

[0026] figure 1 A cross-section of a passive pulsation damper according to the invention, which is suitable, for example, for installation in a hydraulic line system of a power steering of a motor vehicle is shown in simplified outline. according to figure 1 The pulsation damper of the present invention is connected to the hydraulic line either between the input port 3 and the output port 5 or in a branch of the hydraulic line such that the line is connected to the pulsation damper via the connecting line 3a or 5a. The connecting line 3a or 5a leads to a balance chamber 7 which is divided into a hydraulic balance chamber 13 by a membrane 9 , such as a metal membrane, an elastic body or a movable wall.

[0027] The pressure balance chamber 13 is connected with the gas chamber 17 in the energy storage membrane 15 through the through hole 14 . The gas chamber 17 and the energy storage membrane 15 form a so-called gas spring. Of course, mechanical springs or other spring elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com