Process and apparatus for continuous photooxidation preparing polyperfluoromethylethyl ether oil

A technology of methyl ethyl ether and photooxidation, which is applied in the field of preparation of polyperfluoromethyl ethyl ether oil, can solve problems such as peroxide explosion, and achieve a safe and stable reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

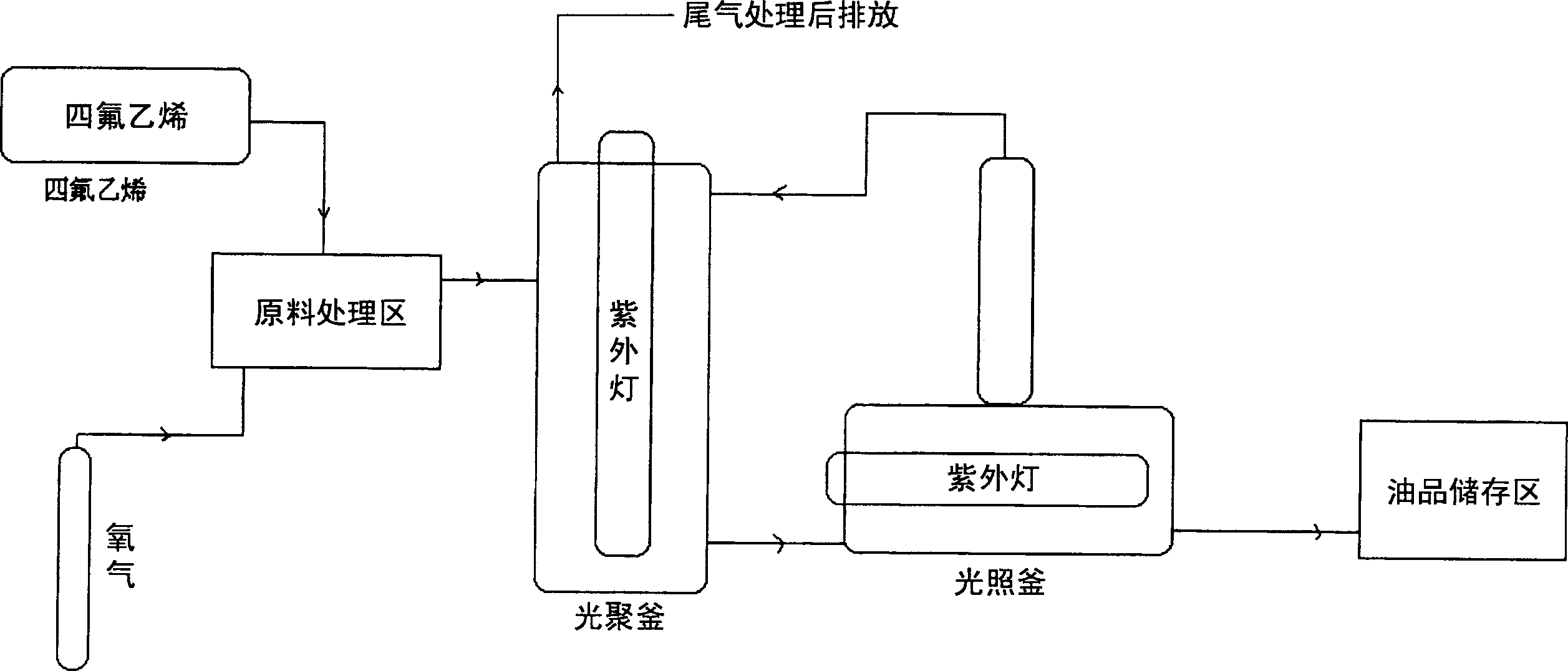

[0015] see figure 1 . The temperature of the photopolymerizer used in this example is -35~-45°C, and the low temperature environment is provided by two 13Kw cascade refrigeration units. The structure of the photopolymerizer is the same as that of the traditional batch reactor, the power of the ultraviolet lamp is 2Kw, and the effective wavelength is 3000mm. Using F12 as a solvent, 3 L / min of tetrafluoroethylene and 4-5 L / min of oxygen are smoothly passed into the photopolymerization tank, and the reaction product is discharged into the photopolymerization tank at an average speed of 0.2 kg / h.

[0016] In fact, the light kettle is a known device, and its structure and working principle will not be described in detail. In the light kettle, the temperature is controlled at 50-65°C, and the synthetic product is irradiated with a 2Kw ultraviolet lamp for 24 hours. Fluoromethyl ethyl ether. The synthesized product is then released for storage for post-processing. In this way, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com