Method and apparatus for vacuum film-coating of small size workpiece

A vacuum coating, small-size technology, applied in the direction of vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problem of reducing the coating speed and small workpiece loading at one time, affecting the coating quality and the reliability of the coating system. Problems such as workpiece dimensional accuracy and appearance quality, to achieve the effect of increasing the effective coating surface area, improving coating production efficiency, and reducing the possibility of scratches and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

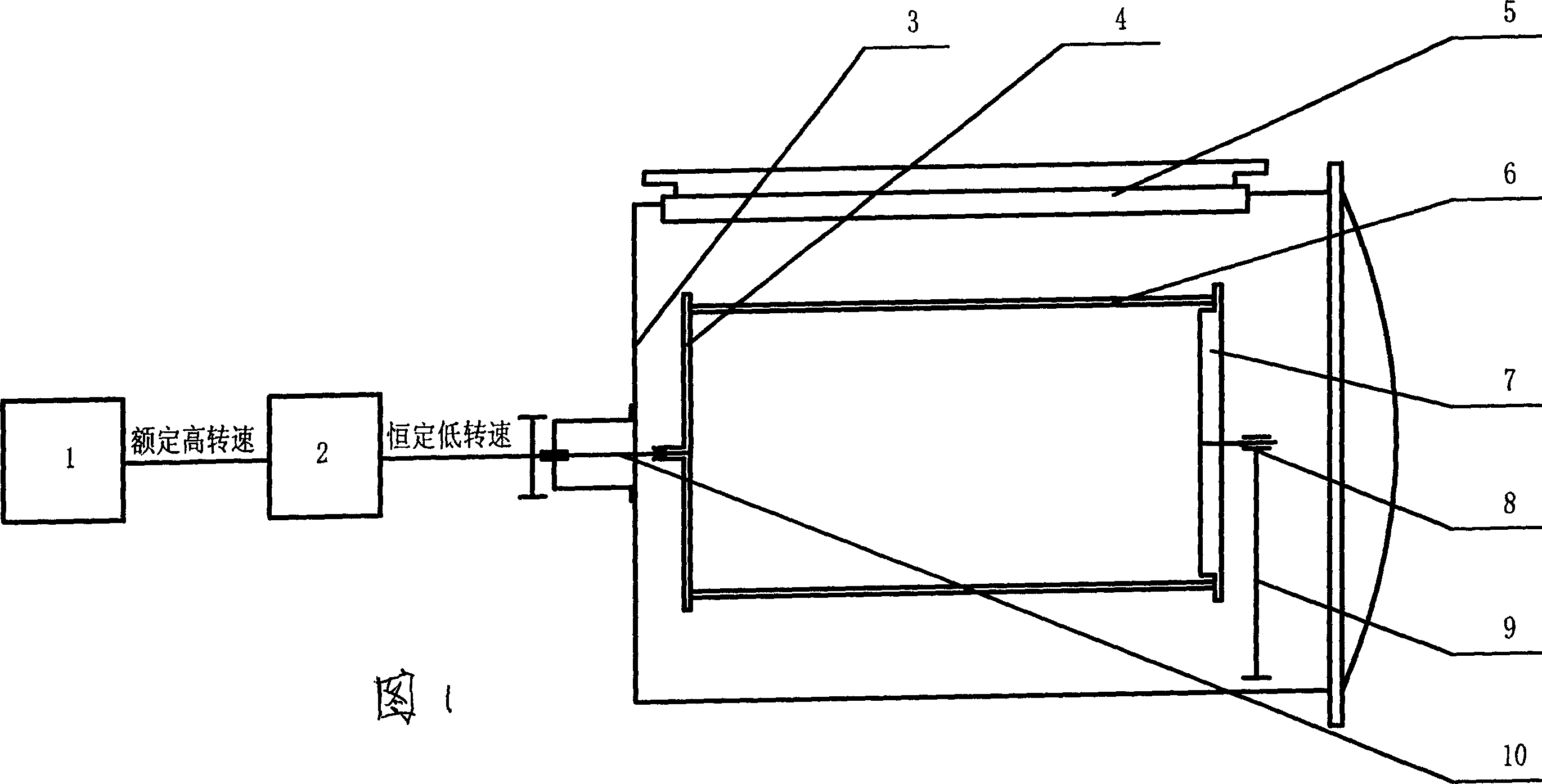

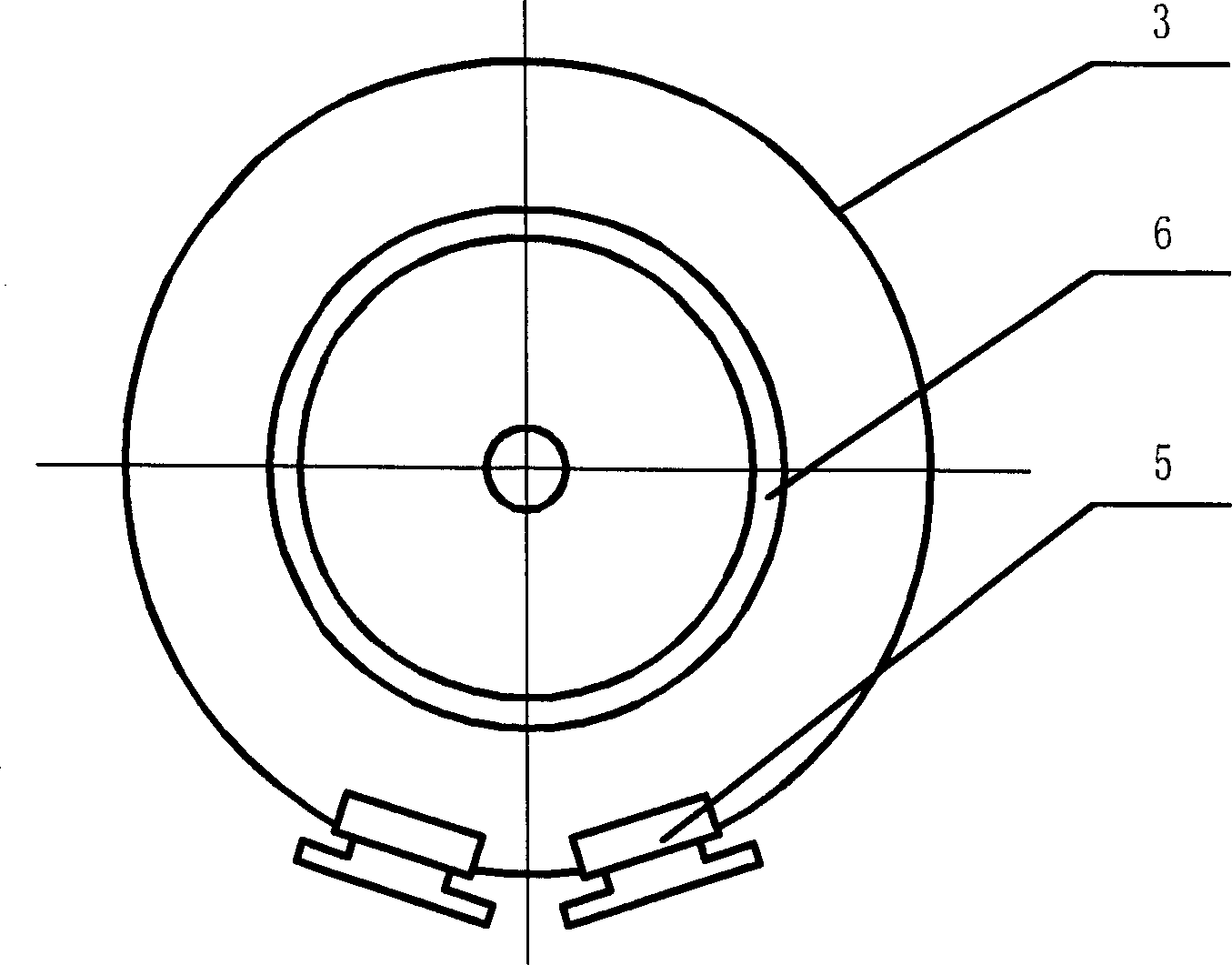

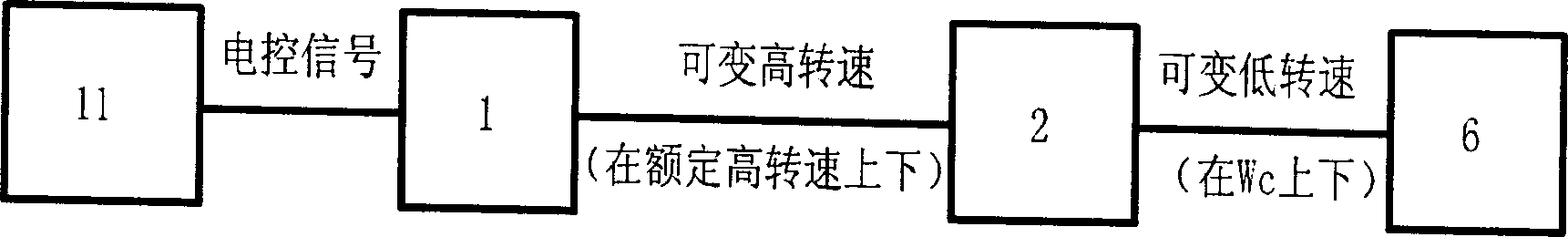

[0028] The device proposed by the present invention for the vacuum coating of small-sized workpieces has a structure such as image 3 and Figure 4 As shown, it includes a motor 1, a reducer 2 and a vacuum coating chamber, wherein the vacuum coating chamber includes a vacuum chamber 3, a mesh cage and an evaporation source 5, and the mesh cage is placed in the vacuum chamber 3, and the motor 1 is connected to the mesh cage through the reducer 2 The rotating shaft connection is characterized in that there are multiple evaporation sources 5, and also includes a control power supply 11. A plurality of evaporation sources 5 are placed on the circumference of the vacuum chamber. The rotating speed of the motor 1 is controlled by a control power supply 11 .

[0029] The cage for small-sized workpieces proposed by the present invention is periodically controlled to rotate at two different rotating speeds (Nd and Nf). Wherein Nd=Nc+Δd, Nf=Nc-Δf, Δd and Δf can be selected between 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com