Method for mfg. large hole diamond coating drawing die

A diamond coating, drawing die technology, applied in metal material coating process, coating, wire drawing die and other directions, can solve the problems of increased recombination probability, decreased surface temperature, decreased coating quality and growth rate, etc., to achieve friction The effect of small coefficient and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand the technical solution of the present invention, further detailed description will be given below in conjunction with the accompanying drawings and embodiments.

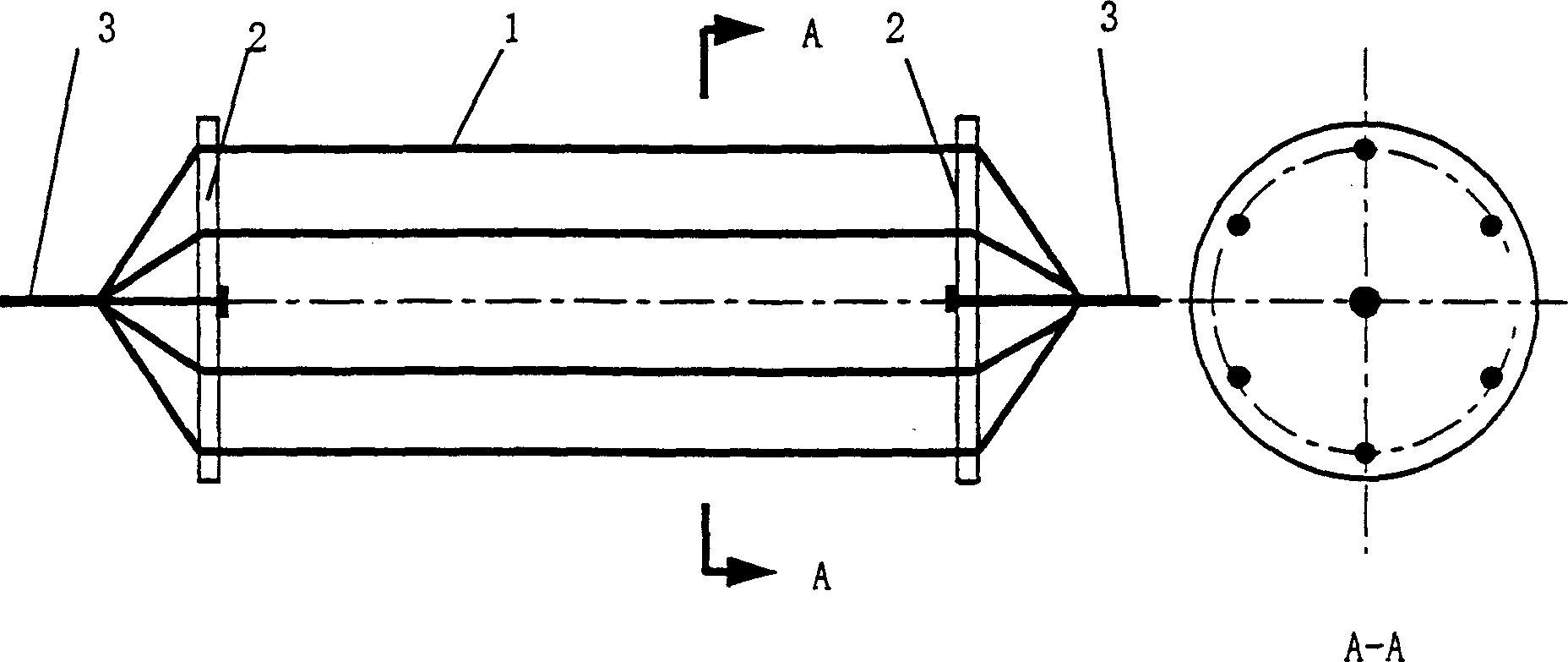

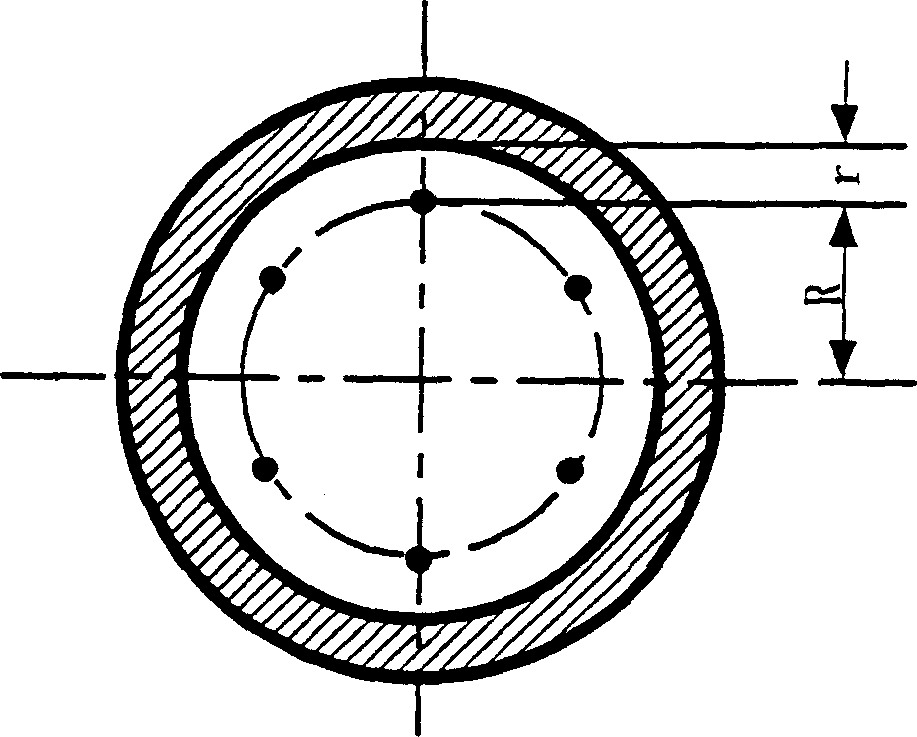

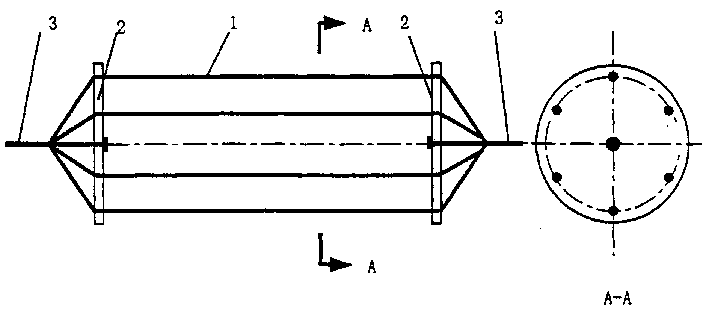

[0016] Such as figure 1 As shown, the squirrel-cage hot wire assembly is composed of a hot wire 1 and a round molybdenum sheet 2 for fixing the hot wire. There are 6 hot wires 1 and the round molybdenum sheet 2 is about 1.5-2 mm thick. Six small holes are evenly distributed on the edge to allow the hot wires to pass through and separate the hot wires evenly. The center of the circular molybdenum sheet 2 is fixed with a section of hot wire, and the two ports are twisted with other hot wires 1 to form a stranded hot wire 3.

[0017] The invention adopts a squirrel-cage hot wire assembly to replace the position of a single hot wire connected with the electrode, and makes the assembly axis coincide with the inner hole axis of the drawing die. In the CVD deposition process, the hot wire a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com