Slurry regulating process of preparing multicomponent composite fertilizer

A technology of compound fertilizer and slurry, which is applied in the direction of fertilizer mixture, fertilizer form, fertilization device, etc., to achieve the effect of improving enterprise benefit, uniform content, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

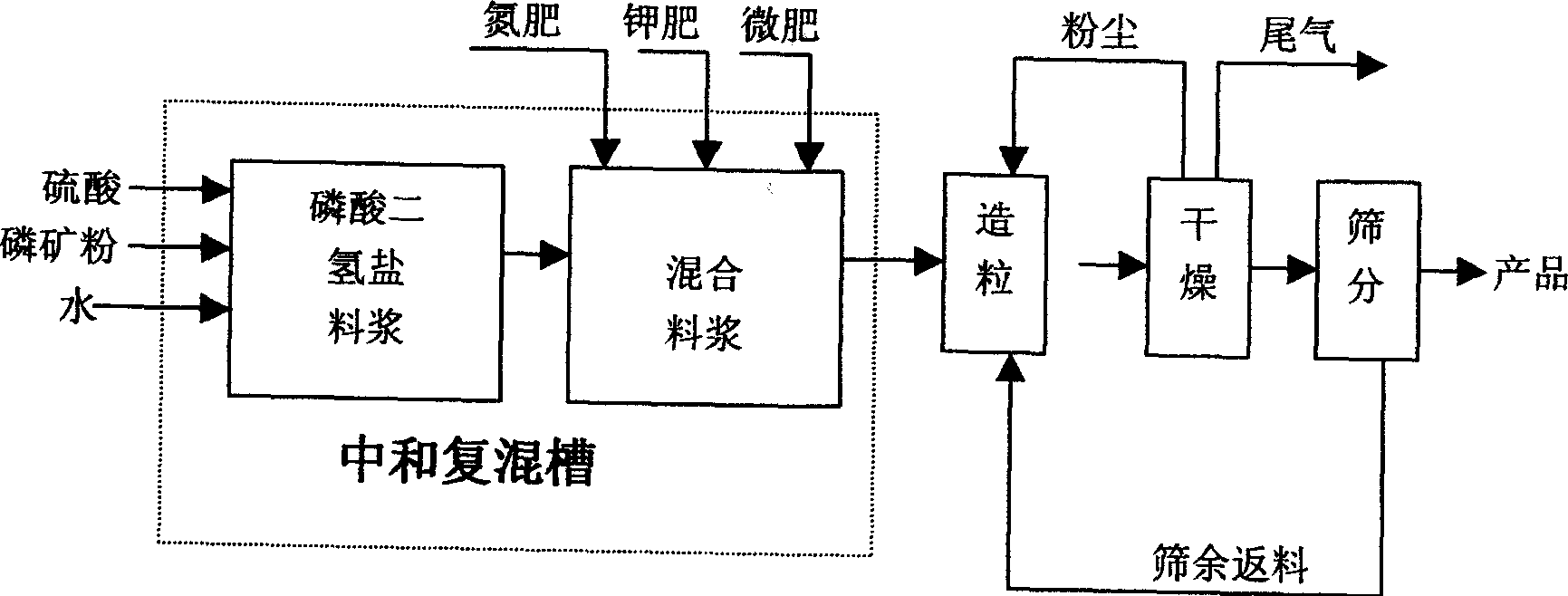

[0024] according to figure 2 According to the technological process, 1000 kilograms of popular compound fertilizers are prepared. The specific operation steps are as follows:

[0025] (1) Preparation of dihydrogen phosphate slurry: get the following material in parts by weight and add it to the neutralization compound tank ("single tank single paddle large circulation extraction mixing reaction tank" for another utility model patent application), stir at normal temperature After reacting for 3-5 hours, 350-550 kg of dihydrogen phosphate slurry was obtained.

[0026] Sulfuric acid (98%) 500

[0027] Phosphate rock powder (≤28%) 1000---1500

[0028] Water 2000---3000

[0029] Optimized: Sulfuric acid (98%) 500

[0030] Phosphate rock powder (≤28%) 1100---1400

[0031] Water 2200---2600

[0032] Optimum: Sulfuric acid (98%) 500

[0033] Phosphate rock powder (≤28%) 1250

[0034] Water 2500.

[0035] ...

Embodiment 2

[0049] according to figure 2 The technical process for preparing 1000 kg of compound fertilizer for field crops. What is different from embodiment one is that step (2) proportioning is changed into:

[0050] Dihydrogen phosphate slurry 300--520 Ammonium chloride 300-500

[0051] Potassium chloride 70--250 Trace elements <5

[0052] Optimized: Dihydrogen Phosphate Slurry 350-450 Ammonium Chloride 350-450

[0053] Potassium chloride 175-220 trace elements a small amount

[0054] Optimal: Dihydrogen Phosphate Slurry 514 Ammonium Chloride 400

[0055] Potassium Chloride 81 Trace Elements 5.

[0056] Other steps are the same as in Example 1 to obtain the product compound fertilizer for field crops.

Embodiment 3

[0058] according to figure 2 According to the technological process, 1000 kilograms of tobacco compound fertilizers are prepared. What is different from embodiment one is that step (2) proportioning is changed into:

[0059] Dihydrogen phosphate slurry 280-480 Urea 100-224

[0060]Potassium sulfate 370-570 Trace element small amount

[0061] Optimized: Dihydrogen Phosphate Slurry 320-430 Urea 130-170

[0062] Potassium sulfate 420-520 Trace elements <5

[0063] Optimum: dihydrogen phosphate slurry 465 urea 220

[0064] Potassium sulfate 310 Trace elements 5

[0065] Other steps are still the same as in Example 1 to obtain the product tobacco compound fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com