Optical recording medium

一种光学记录介质、记录层的技术,应用在光学记录载体、用光学方法记录/重现、数据记录等方向,能够解决不适用大量生产等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8 and comparative Embodiment 1~8

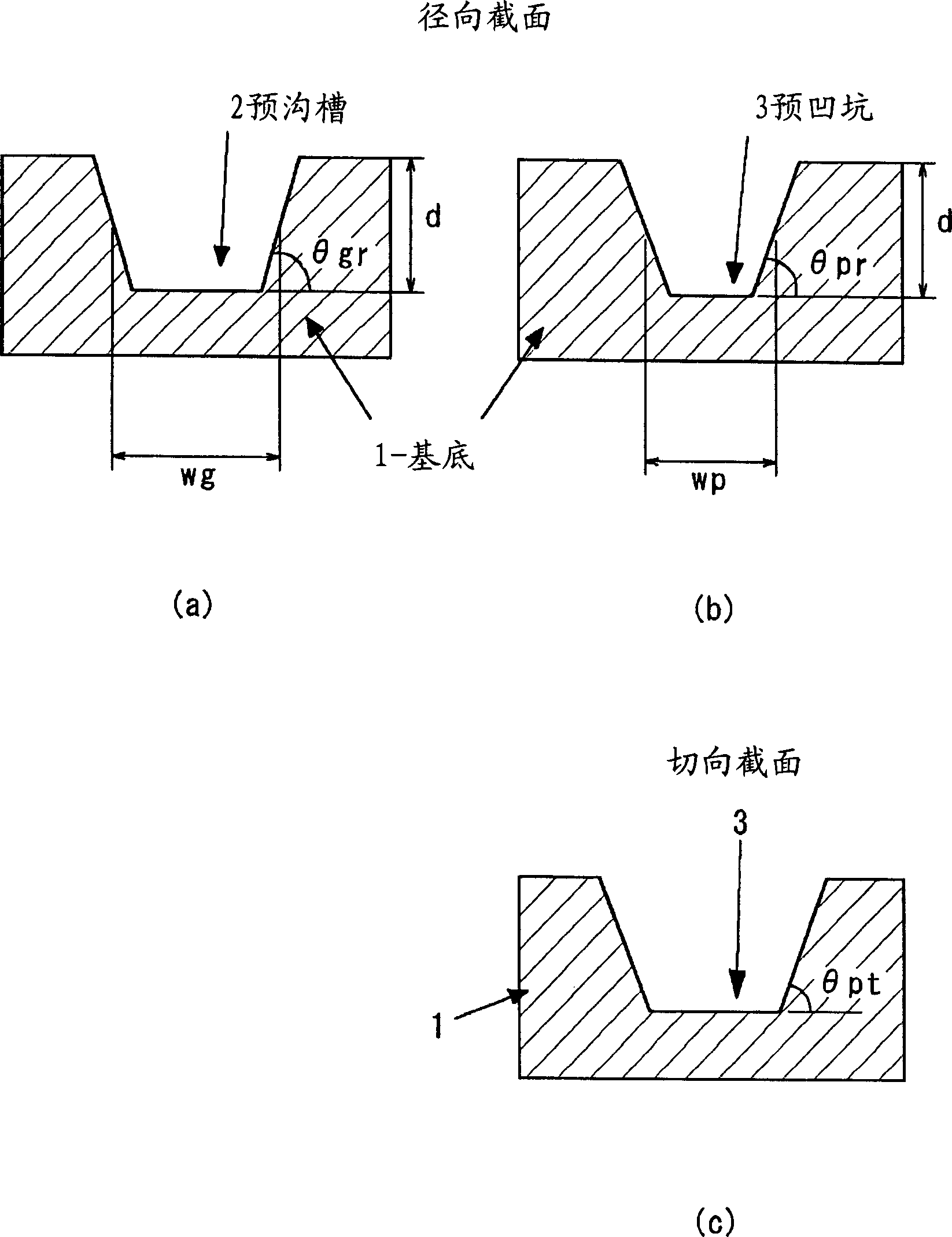

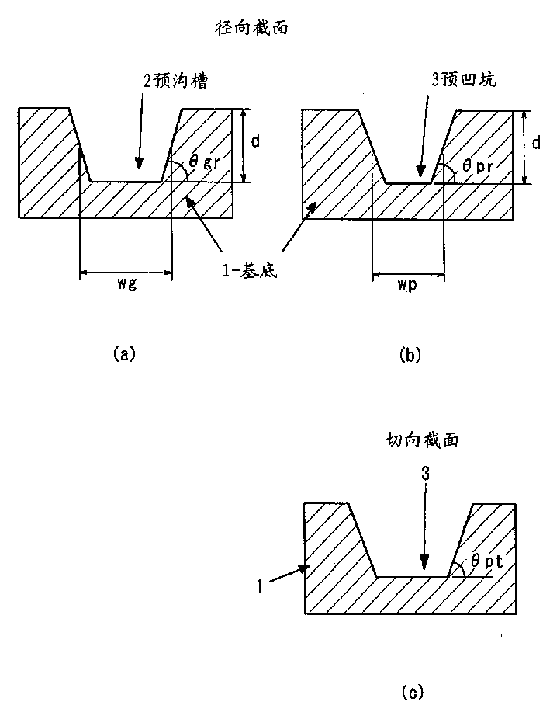

[0059] A 20 g / l solution of one of the pyrrolomethylene dyes represented by structural formulas (A) to (C) in ethylcyclohexane was spin-coated on an injection-molded polycarbonate substrate to form a dye layer, the substrate It has a thickness of 0.6 mm, a diameter of 120 mmΦ, a helical groove with a pitch of 0.74 μm, and a pre-pit on the extension line of the pre-groove that is partially introduced into the area. A 100 nm Au reflective layer was deposited on the dye layer by sputtering. The product was then coated with a UV curable resin SD-17 (Dainippon Ink And Chemicals, Inc.) and UV cured. The aforementioned polycarbonate substrate having a thickness of 0.6 mm was laminated on the resin layer by Z8412 (JSR) radical type adhesive to prepare an optical recording medium.

[0060]The signal modulation coefficient (I14 / I14H) of the optical recording medium was evaluated according to the DVD specification requirements of pre-pits at a wavelength of 658 nm and an NA of 0.60 with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com