Composite electrical heating process and its apparatus

An electric heating and process technology, applied in glass furnace equipment, glass manufacturing equipment, electric furnaces, etc., can solve the problems of silicon carbide rod baking cellars being easily damaged, long start-up time, and cold start-up time, and achieve ideal energy-saving effects and improve The effect of production efficiency and simple equipment structure

Inactive Publication Date: 2003-04-02

郭永强 +2

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the main forms of heat connection commonly used at home and abroad are: (1) directly making rock wool from the high-temperature cyclone furnace slag; There is a certain distance between the outlet of the cyclone slag and the cotton four-roller, and there must be a diversion process, and its equipment is called a diversion tank

The disadvantage of this method is: the start-up process is time-consuming and labor-intensive, and the silicon carbide rod baking cellar is also easily damaged; once the diversion tank fails, cold start cannot be achieved

Although cold start can be achieved, due to the low thermal conductivity of the heated material, the start-up time is very long, and the moving guide groove is very easy to cause damage to the silicon carbon molybdenum rod, which affects normal production; (4) The method of burning with fuel , reheating the slag

The main disadvantage of this method is that the efficiency is low, cold start cannot be realized, or the cold start time is very long, and the investment in equipment is also large, and the safety is also poor.

[0003] In addition, for arc heating, since the heating equipment adopts an open structure, the heat loss is large, and its environmental problems are relatively serious, and the quality of the final product generated from this cannot be fully guaranteed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

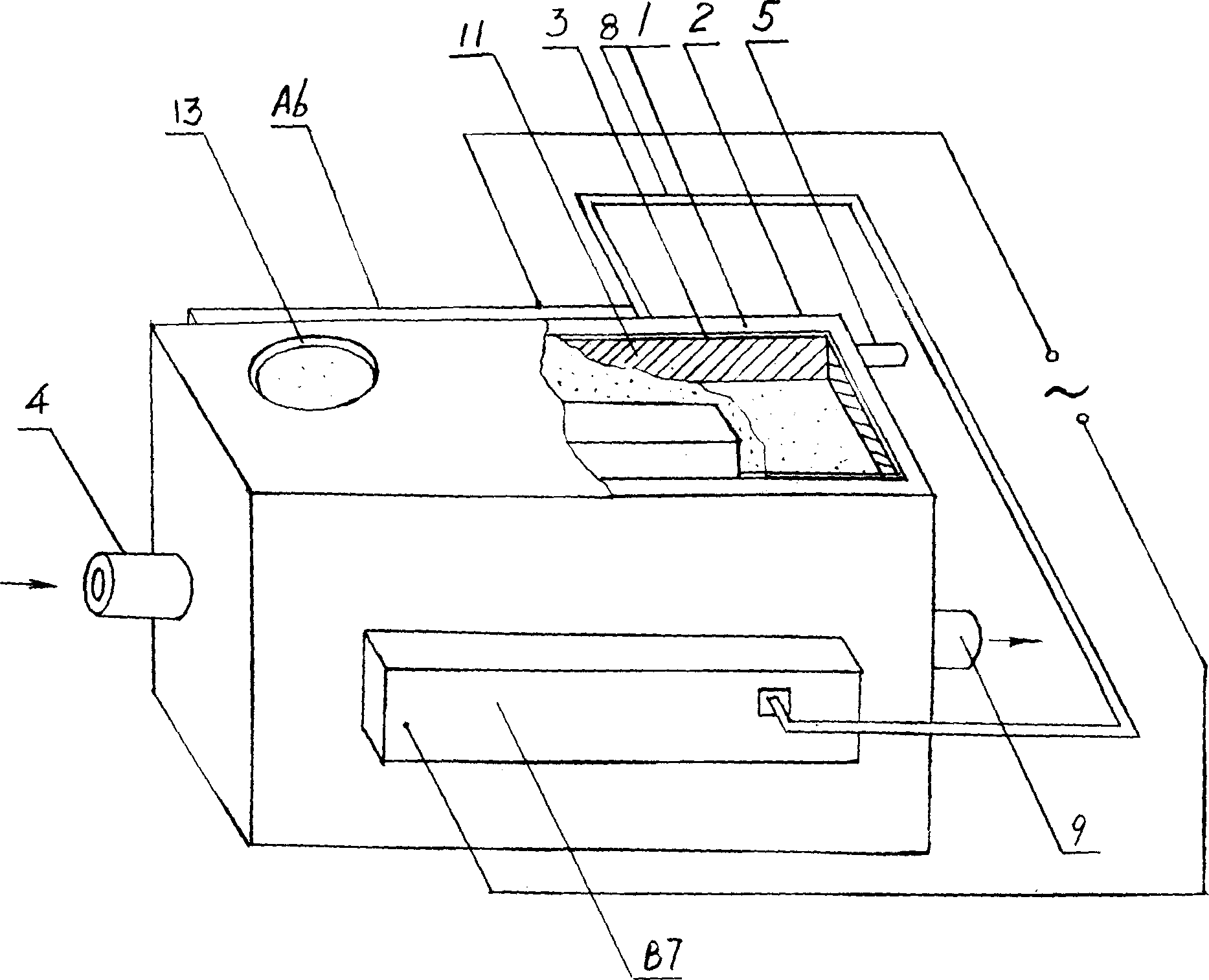

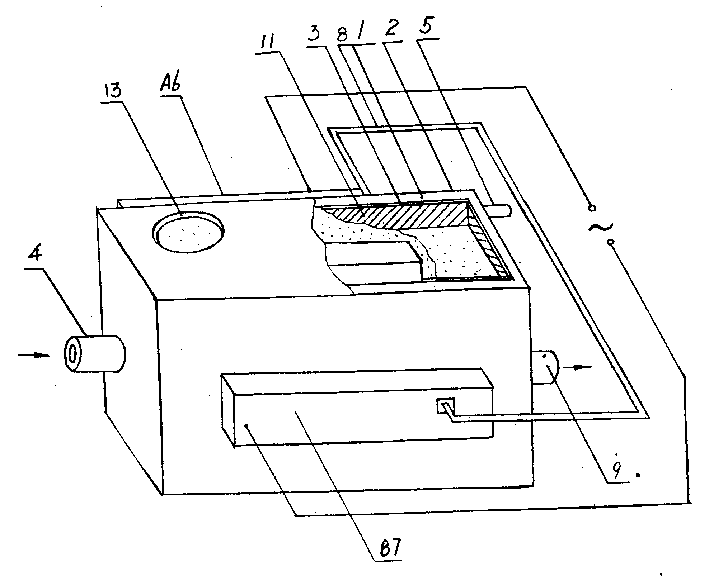

[0020] figure 1 It is a schematic diagram of the overall structure of the heating furnace of the present invention;

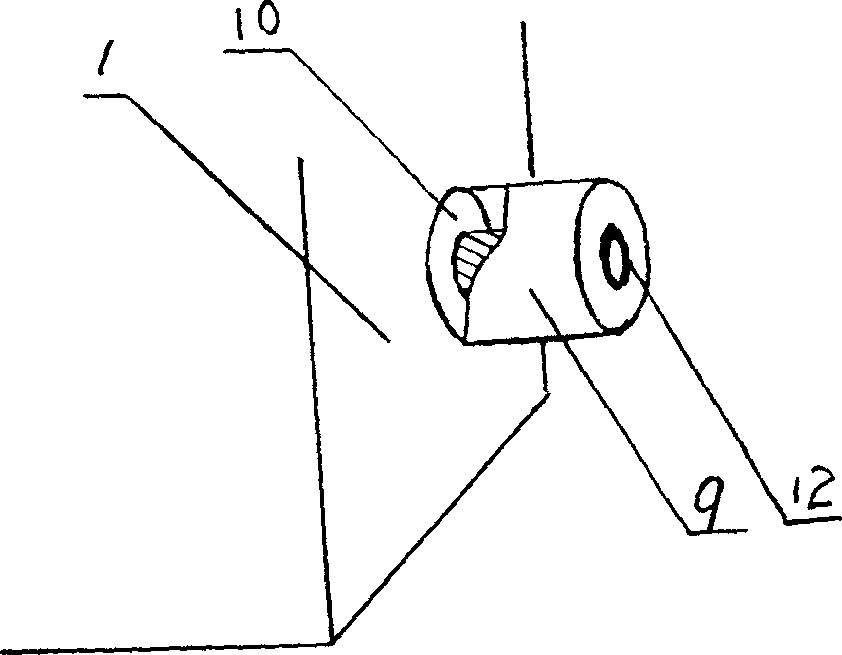

[0021] figure 2 It is a schematic diagram of the partial structure of the outlet of the heating furnace of the present invention;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A process for reclaiming high-temp liquid slag includes such steps as feeding the high-temp liquid slag in heater, serially connecting two plate electrodes by external water cable, electrically heating the slag to 1400-1700 deg.C and removing the water cable after the charge in heater becomes electric conductive. Its apparatus is composed of external liner, refractory corundum layer, cooling medium inlet and outlet, and plate electrodes.

Description

technical field [0001] The invention belongs to the technical field of harmless utilization of high-temperature liquid waste residue, and in particular relates to a high-temperature liquid waste residue composite electric heating process and the field of equipment thereof. Background technique [0002] The method of producing rock wool with high-temperature cyclone furnace slag has many applications at home and abroad. At present, the main forms of heat connection commonly used at home and abroad are: (1) directly making rock wool from the high-temperature cyclone furnace slag; There is a certain distance between the outlet of the cyclone slag and the cotton four-roller, and there must be a diversion process, and the equipment is called a diversion tank. Since the slag in the diversion tank is not supplemented by energy, it is easy to form a hard block, which seriously affects the stability and continuous production. (2) Use silicon-carbon baking ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03B5/033C03B5/16C03B37/00

Inventor 郭永强顾根华郭凤翔

Owner 郭永强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com