Exposure device and method

The technology of an exposure device and an exposure method is applied in the direction of exposure device of photoengraving process, printing device, microlithography exposure equipment, etc., and can solve the problem of low illumination and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

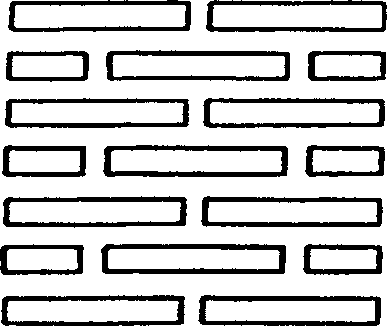

[0112] In the exposure apparatus, due to the progress in the miniaturization of the pattern size, when the k1 factor (line width=k1×λ / NA, λ is the wavelength, and NA is the numerical aperture) becomes smaller, the analytical size will diverge from the target size. There is an abnormal line width phenomenon, or a phenomenon in which the fidelity to the screen pattern of the photoresist pattern is deteriorated, or a phenomenon in which the dependency of the type of the resolving power is significantly increased. For example, in the design, the pattern angle of a 90-degree image may become rounded, or the end of the line may become shorter, or the width of the line may increase or become thinner. These phenomena are collectively referred to as Optical Proximity Effect (OPE: Optical Proximity Effect).

[0113] This OPE originally refers to the effect of light caused by transfer, however, recently, with the increase of optical effects, it is also used for photoresist processes incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com