Device and method for preparing and supplying polymerization inhibitor

A technology of a polymerization inhibitor and stirring device, which is applied in chemical instruments and methods, mixing methods, transportation and packaging, etc., can solve the problems of reducing the efficiency of target preparation operations, violating weight preparation, and spending a lot of time and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

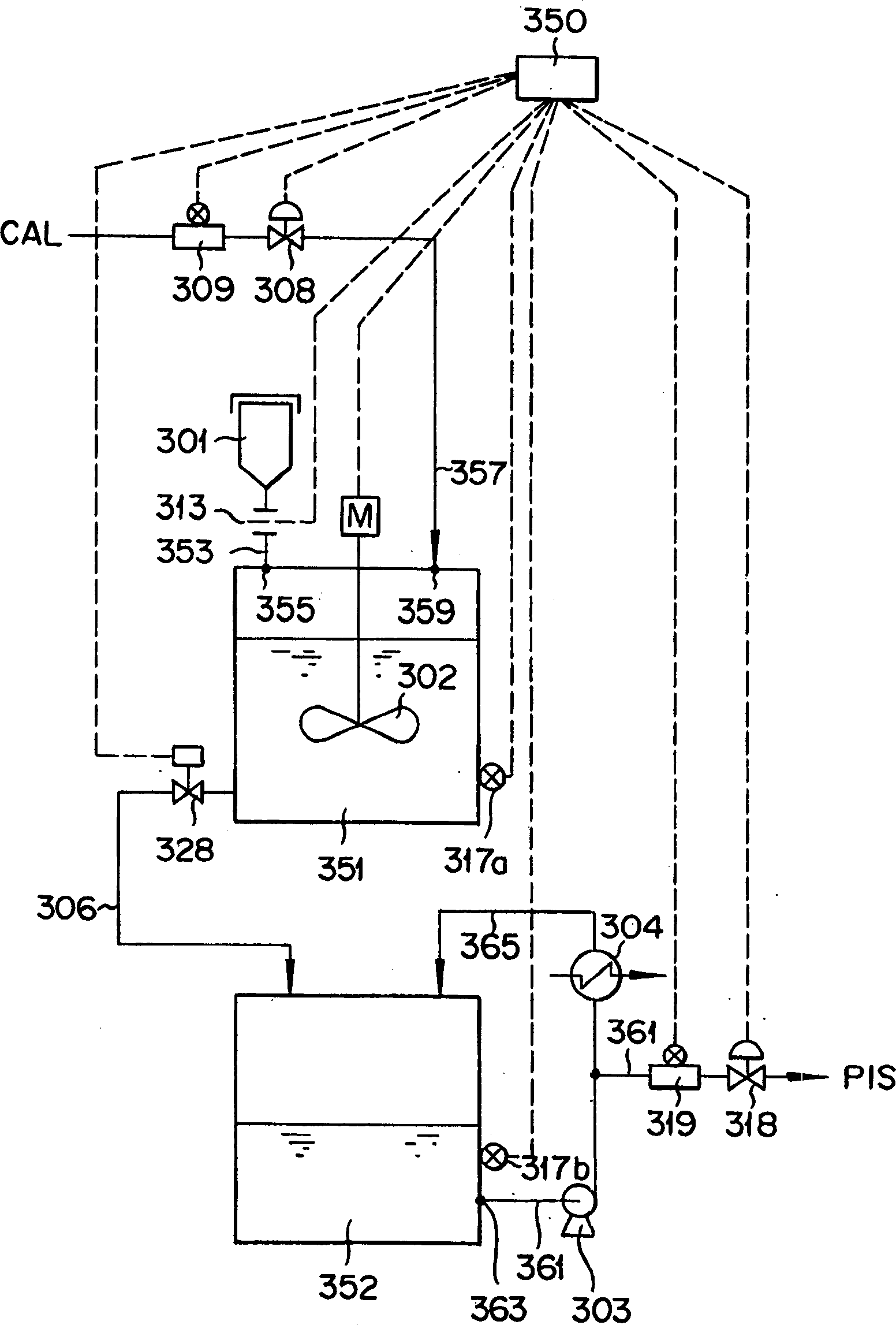

[0094] The above-mentioned preparation tank (A) 351 is equipped with a liquid level detector 317a to detect the liquid level of the tank. For the same reason, the above-mentioned supply tank (B) 352 is equipped with a liquid level detector 317b to detect the liquid level of the tank. Furthermore, these detectors are connected to the control device 350 .

[0095] The preparation tank (A) 351 is provided with a polymerization inhibitor input port 355 on its upper portion. Furthermore, in order to supply a polymerization inhibitor into the preparation tank (A) 351 , the feed hopper 301 is connected to a polymerization inhibitor input port 355 via a pipe 353 .

[0096] As a means for controlling the amount of polymerization inhibitor introduced into the above-mentioned preparation tank (A) 351 , the pipe 353 is provided with a gate valve 313 on its line. Furthermore, these gate valves 313 are connected to a control device 350 .

[0097] By the way, this embodiment can consider ...

Embodiment 1

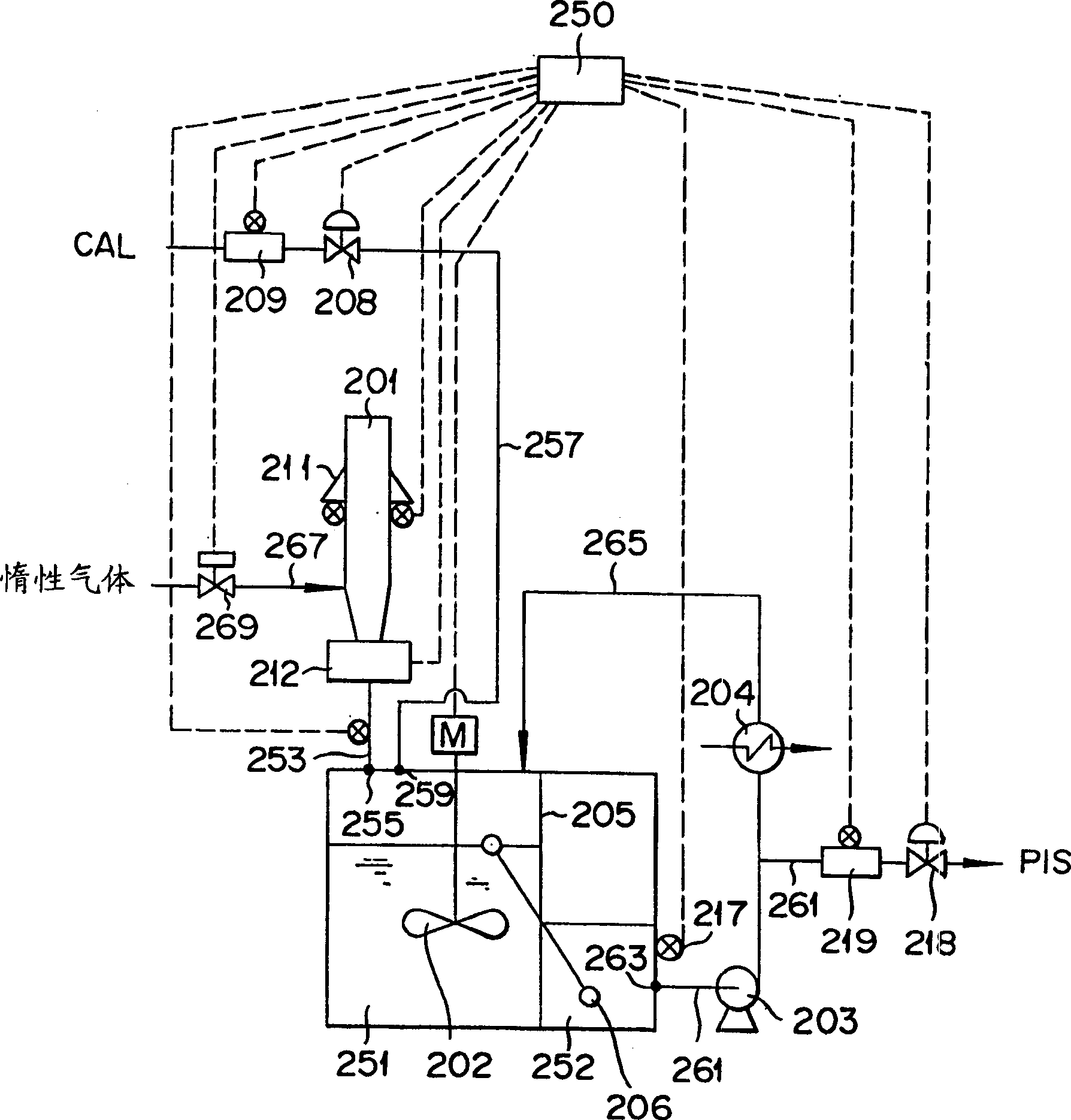

[0172] figure 2 The apparatus shown in was used for the preparation and supply of the inhibitor. with 5m 3 The inner volume of the vertical cylindrical storage tank made of stainless steel (SUS 304) was divided into two tanks with a partition 205. The separate tanks are interconnected with pipes 206 . Larger tanks have 4m 3 internal volume, smaller tanks have 1m 3 inner volume. The larger tank 251 is equipped with a propeller type-stirring device 202 to be used as a preparation tank, and the smaller tank 252 is used as a supply tank. In addition, a feed hopper 201 equipped with a load cell, a powder feeding device 212 (available from Taisei Kogyo K.K., Japan, "SmoothAuto Feeder" type), a liquid delivery pump 203 (a pump with a sealed casing), and a screw heat exchanger were used 204. A volumetric flow meter is used as a flow rate meter, and a differential pressure liquid level meter is used as a liquid level meter.

[0173]CAL consisting of 100 wt% of acrylic acid and...

Embodiment 2

[0177] In contrast to Example 1, in image 3 The apparatus shown in was used for the preparation and supply of the inhibitor. with 5m 3 The internal volume of , and two vertical cylindrical tanks made of stainless steel (SUS304) were installed to form a preparation tank and a supply tank equipped with a propeller type stirring device. A feed hopper 301, a liquid transfer pump 303 (a pump with a sealed casing), and a spiral heat exchanger 304 may also be used. A volumetric flow meter is used as a flow rate meter, and a differential pressure liquid level meter is used as a liquid level meter.

[0178] The composition of liquid and polymerization inhibitor, flow velocity, and the concentration of setting are the same as in Example 1.

[0179] The CAL is continuously introduced to the preparation and supply tanks so that the total liquid volume is controlled at a fixed level. The phenothiazine is introduced by opening the valve 313 after reaching the stop regulation level ① sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com