Positive optical controller of reflective schmidt correcting plate

A controller, Schmidt's technology, used in the research and application of astronomical telescopes, can solve the problems of poor anti-interference ability, difficult maintenance and upgrade, and many hardware wiring, etc., to achieve easy upgrade operation, simple structure, strong anti-interference ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

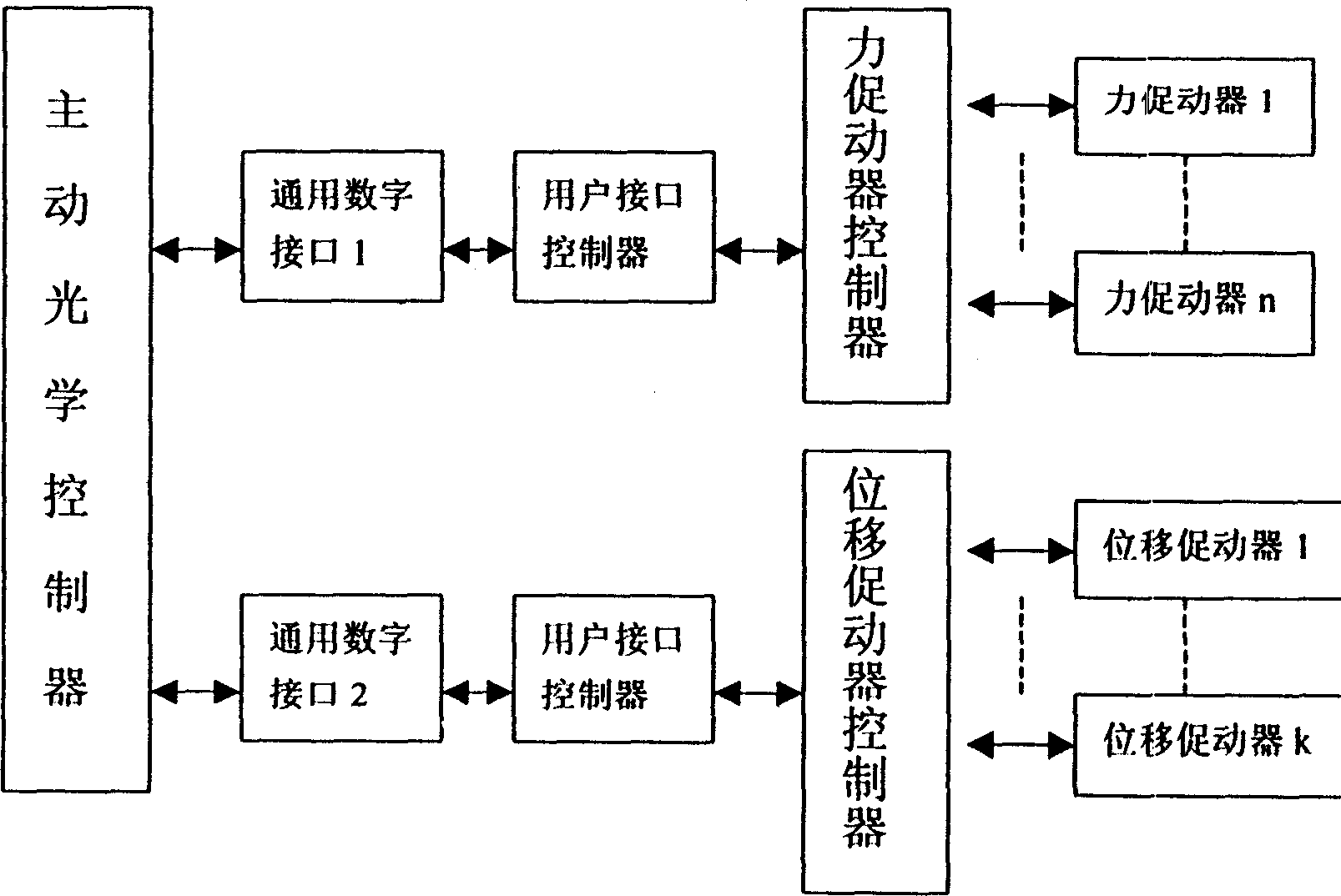

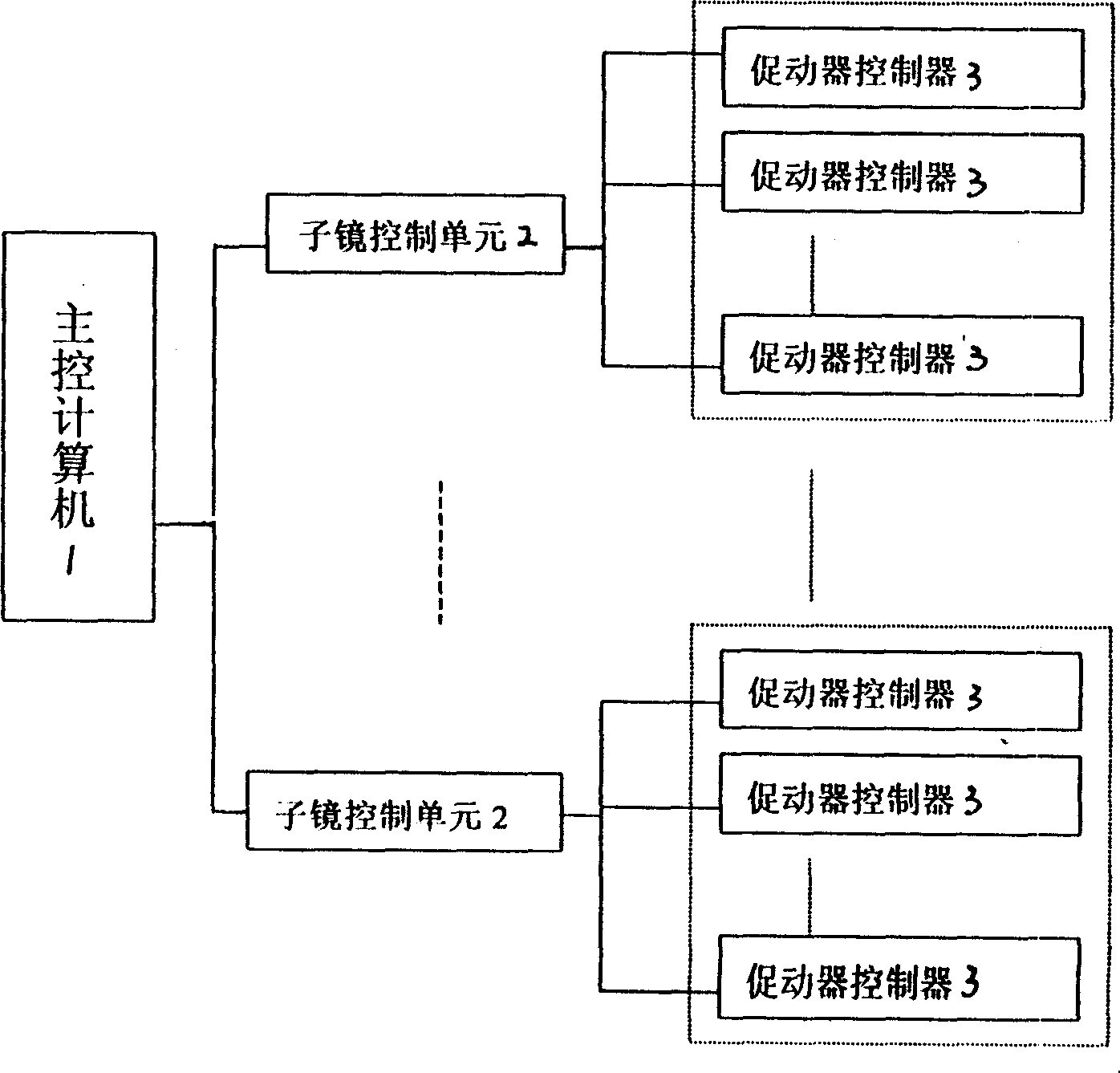

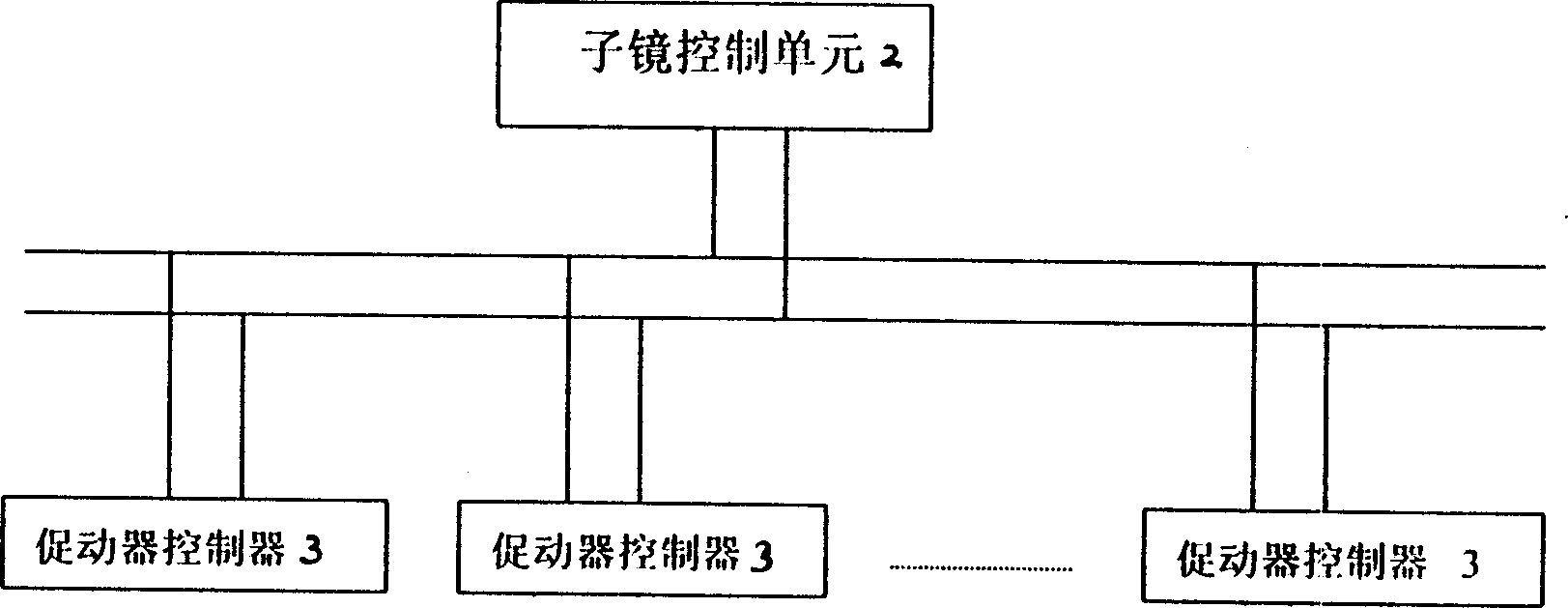

[0017] like figure 2 As shown in ~ 6, the present invention is made up of main control computer 1, 24 sub-mirror control units 2, 30 actuator controllers 3, wherein: a sub-mirror is connected with a sub-mirror control unit 2, and a sub-mirror control unit 2 Control, each actuator is connected to an actuator controller 3, controlled by an actuator controller 3, the main control computer 1 is used as the active optical controller to form the upper layer control, and the sub-mirror control unit 2 is connected through the Ethernet interface , the sub-mirror control unit 2 constitutes the middle layer control, is connected with all actuator controllers 3 through the field bus, and transmits various information through the field bus, monitors and controls the operating status of the sub-mirror; the actuator control The bottom layer control is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com