Method for maintaining position of thin belt

A transmission belt, thin-shaped technology, applied in the field of mechanical deviation correction, can solve problems such as cracking, deformation of the side of the transmission belt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

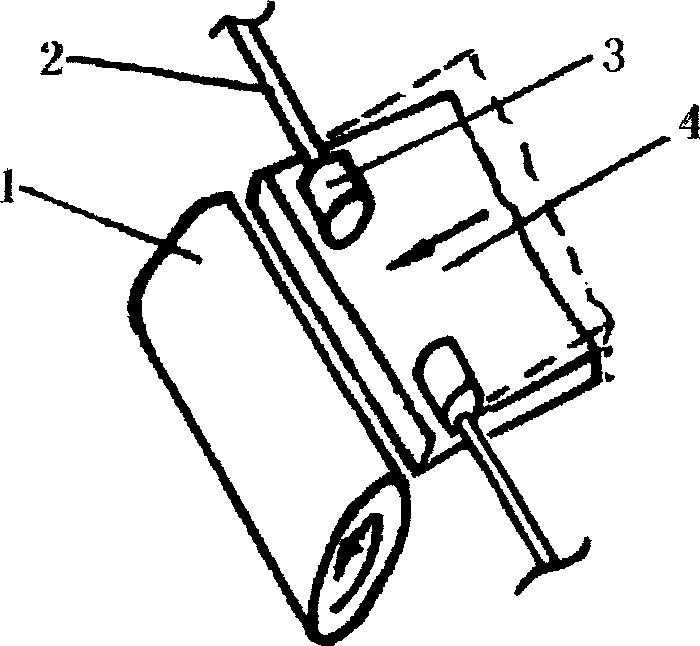

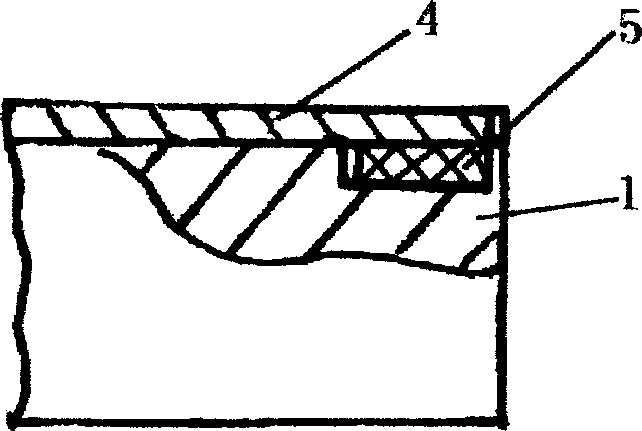

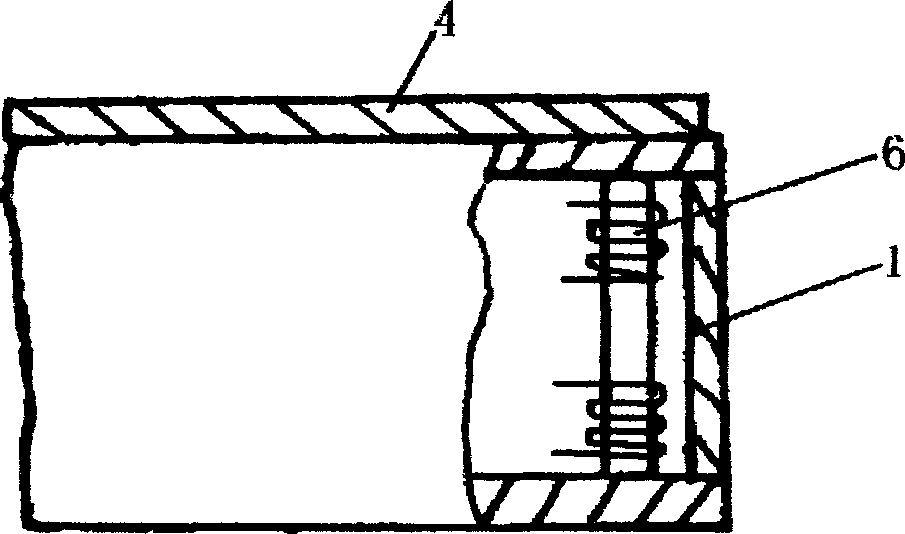

[0012] The invention is a deviation correcting method for a thin transmission belt. The thin-shaped transmission belt moves under the drive of the transmission roller, and deviation phenomenon will inevitably occur during the movement process, thus affecting the normal production. Using magnetic force correction and grinding pressure correction can reduce or prevent deviation. Magnetic correction is divided into two types: permanent magnet and electromagnetic. Be explained below in conjunction with accompanying drawing:

[0013] figure 1 It is a schematic diagram of the structure of the grinding pressure correction device. The thermal transfer substrate on the paperless thermal transfer printing and dyeing test machine is 0.2mm thick aluminum foil. Grinding rollers 3 are arranged above the two ends of the two drive rollers 1 at the entrance and exit of the thermal transfer area, respectively. By detecting the deviation speed of the base material and transmitting this info...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com