Tilting type steel slag water quenching treatment method

A treatment method, water quenching technology, applied in the field of tilting steel slag water quenching treatment, can solve the problems of inability to transport, difficult to clean up, site environmental pollution, etc., and achieve the effect of reducing labor intensity, small particle size, and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

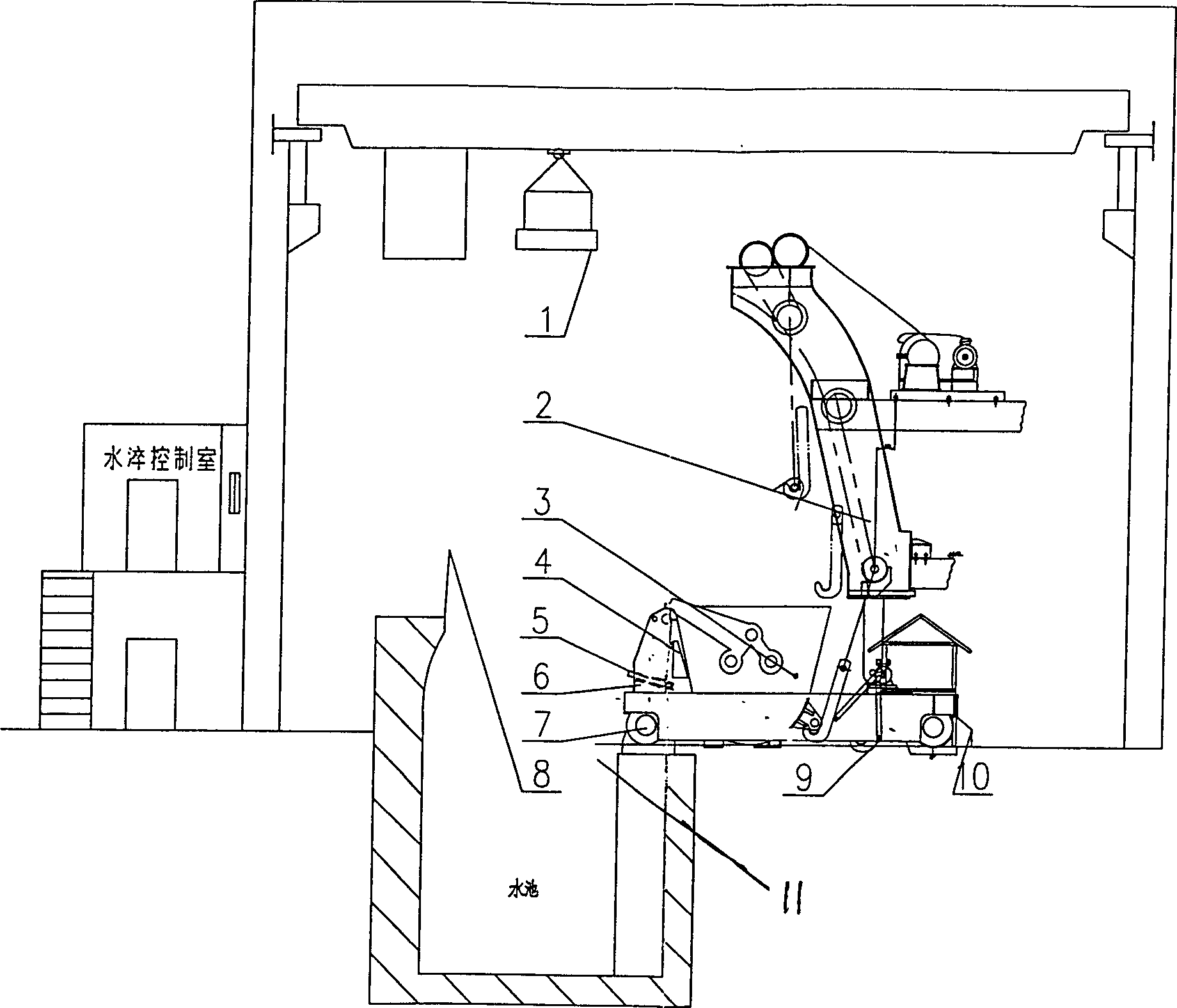

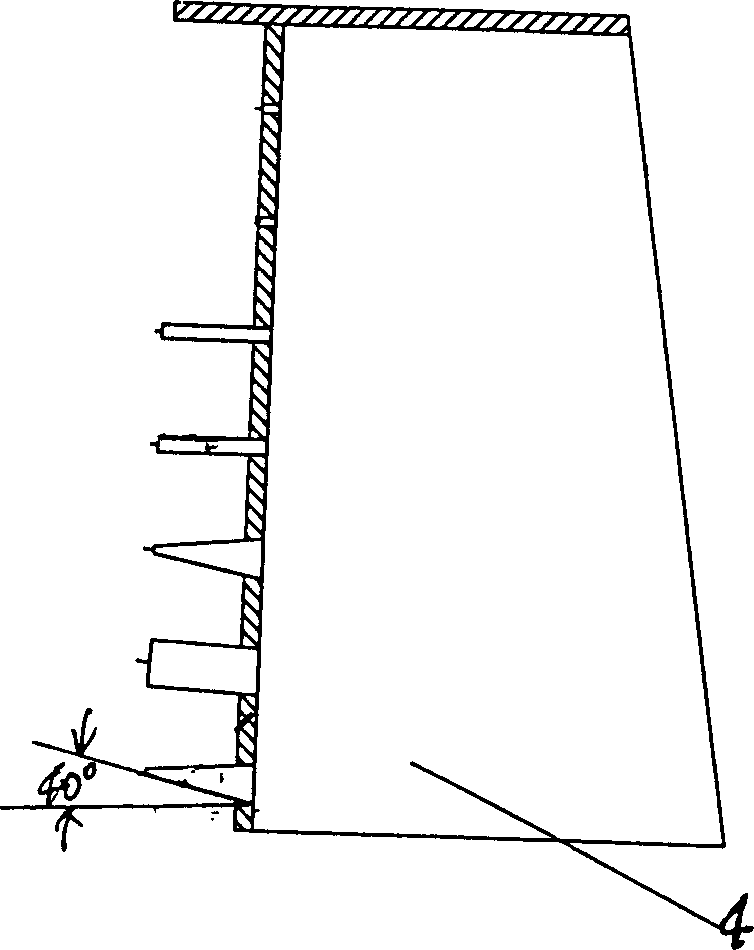

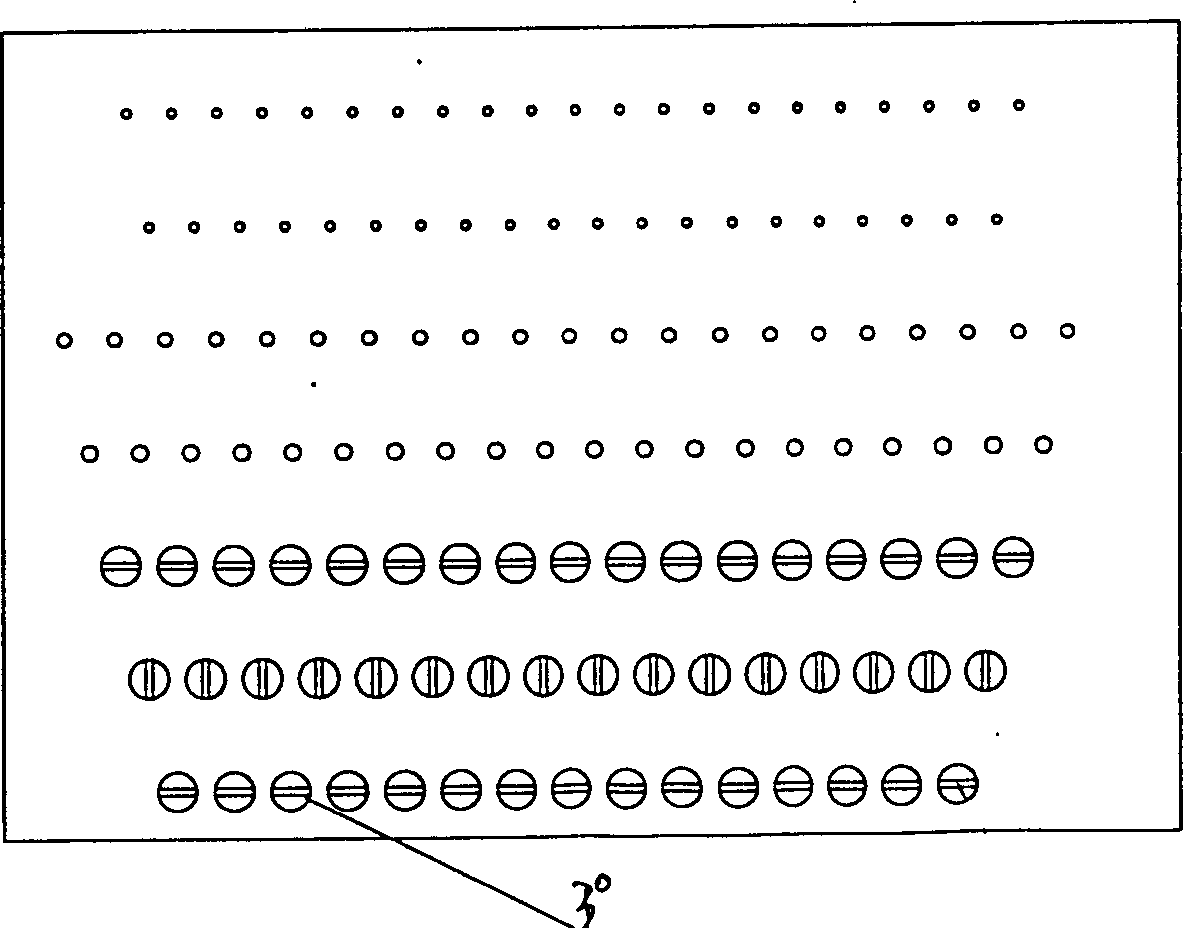

[0007] The processing method of the steel slag of the present invention is as follows: first pour the steel slag into a slag tank, and then transport the steel slag to a room for water quenching treatment. The treatment method is to install a water quenching pool 11 indoors, install a cylinder 6 at the edge of the water quenching pool 11, install a granulator 4 on one side of the cylinder 6, and pour the molten steel slag into the slag tank 3 on the slag tank car 7 Afterwards, it is transported to the water quenching pool 11 and through the cooperation of the hook of the winch 1 and the lifting lug on the slag tank 3, the slag tank 3 is tipped over the steel slag. After turning to a certain angle, the tipping guide arm 13 on the slag tank 3 falls On the cylinder 6, the slag pot 3 rotates around the rotating shaft 12 of the cylinder 6 and slowly tilts the steel slag into the water quenching pool 11. At the same time, the pressurized water of the granulator 4 has been sprayed out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com