Nano composite material of epoxy resin/clay for copper foil base plate

A technology of nanocomposite material and epoxy resin, which is applied in nanocomposite material and its application field, can solve problems such as unsuitability, heat resistance, water absorption and dimensional stability limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Embodiment: add the clay that the present invention is modified with two kinds of modifying agents

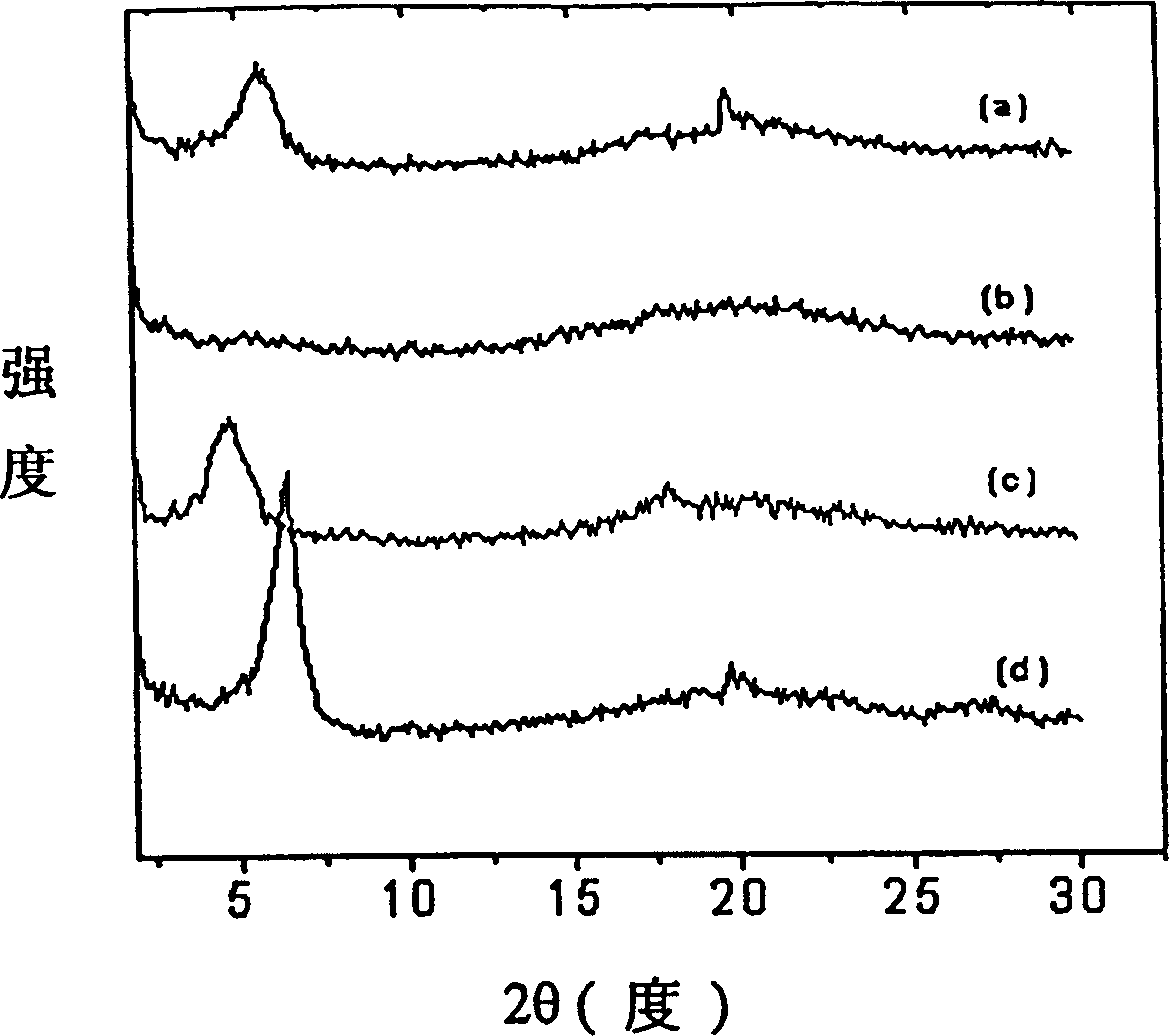

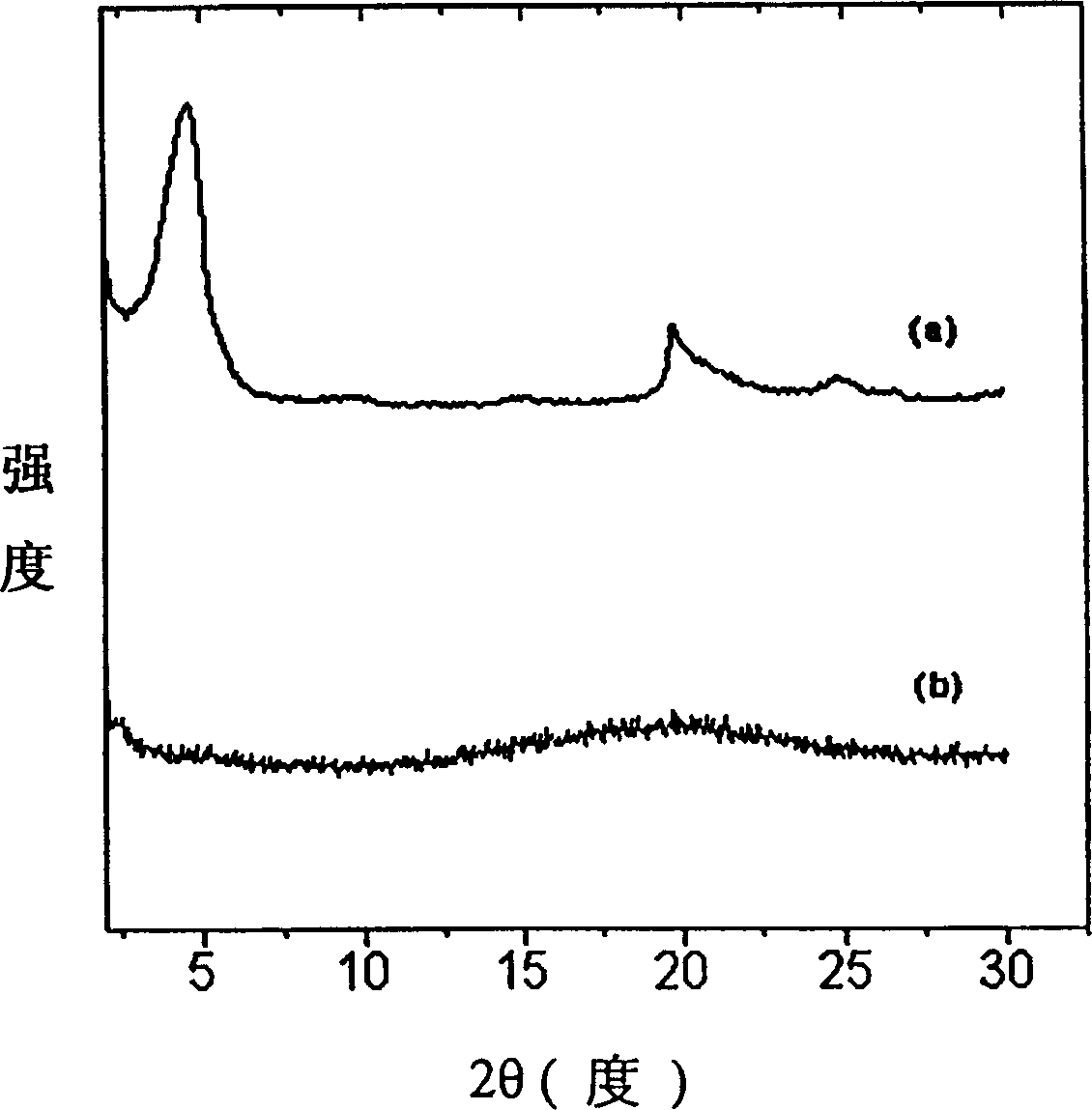

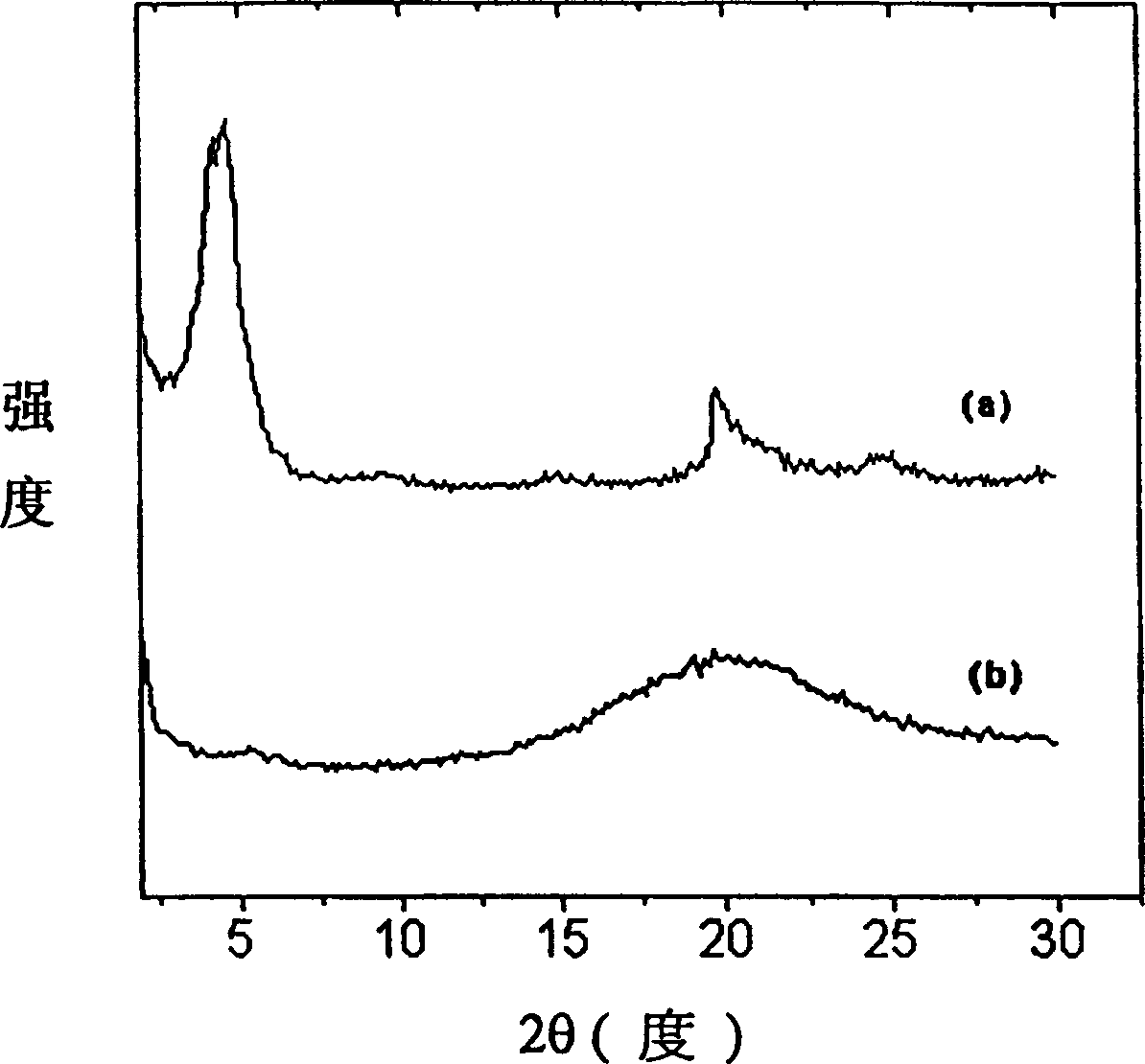

[0030] The clay is modified by mixing DICY and BEN (or TEP and BEN) before use. Disperse 50g of clay evenly in 4500ml of water and swell for more than 4 hours, then slowly add appropriate amount of modifying solution under vigorous stirring: (a) 1.25g DICY, 30ml 1M HCI and 172ml 10wt% BEN aqueous solution or (b ) 2.85g TEP, 20ml 1M HCl or (c) 172ml 10wt% BEN in water. Stirring was continued at room temperature for another 6 hours after this step was completed.

[0031] The clay suspension that has been exchanged is filtered, and the obtained filter cake is washed with deionized water twice, and this is repeated three times. The washed filter cake is dried and crushed. The obtained samples are expressed as NCY / BEN / clay and TEP / BEN / clay, respectively. The preparation of epoxy resin / clay glass fiber substrate is to dissolve 2.6gDICY, 105.6g EB453 epoxy resin and a small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com