Vision controlling platform for opened industrial robot

A technology of industrial robots and control platforms, applied in manipulators, manufacturing tools, etc., can solve the problems of adjusting light intensity, without automatic adjustment of pan/tilt, automatic adjustment of focal length and aperture, and closed structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

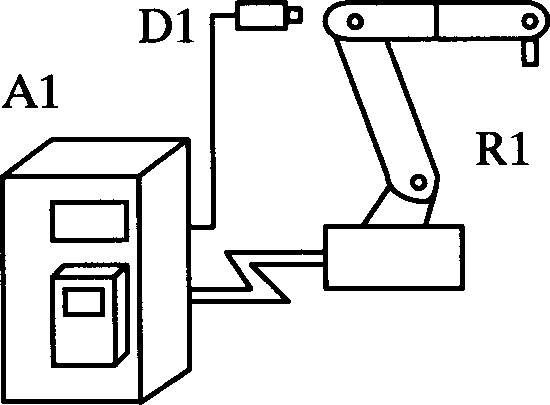

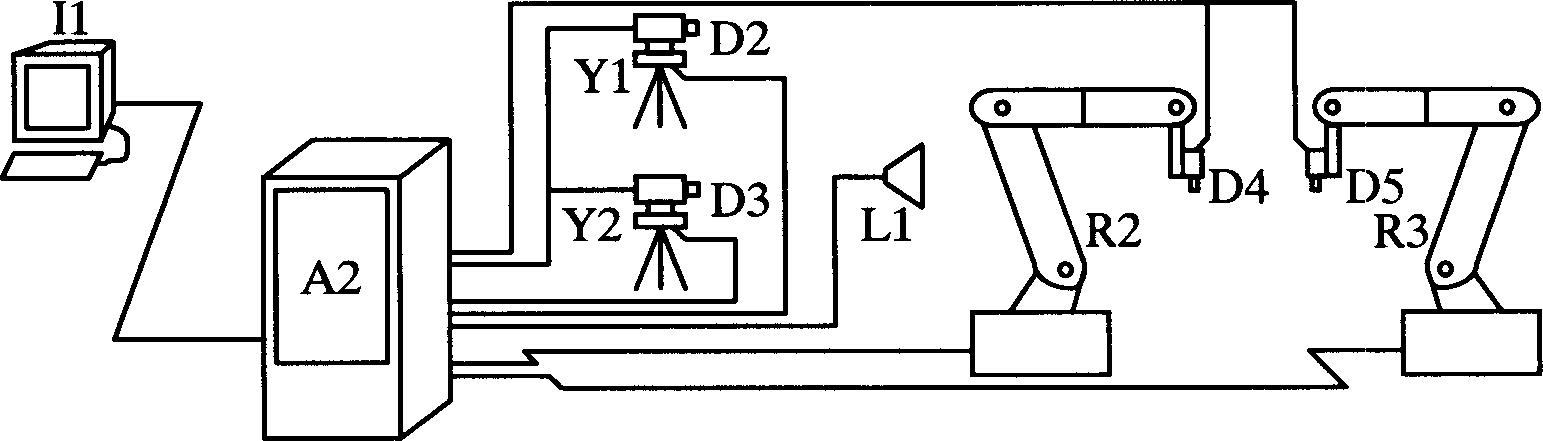

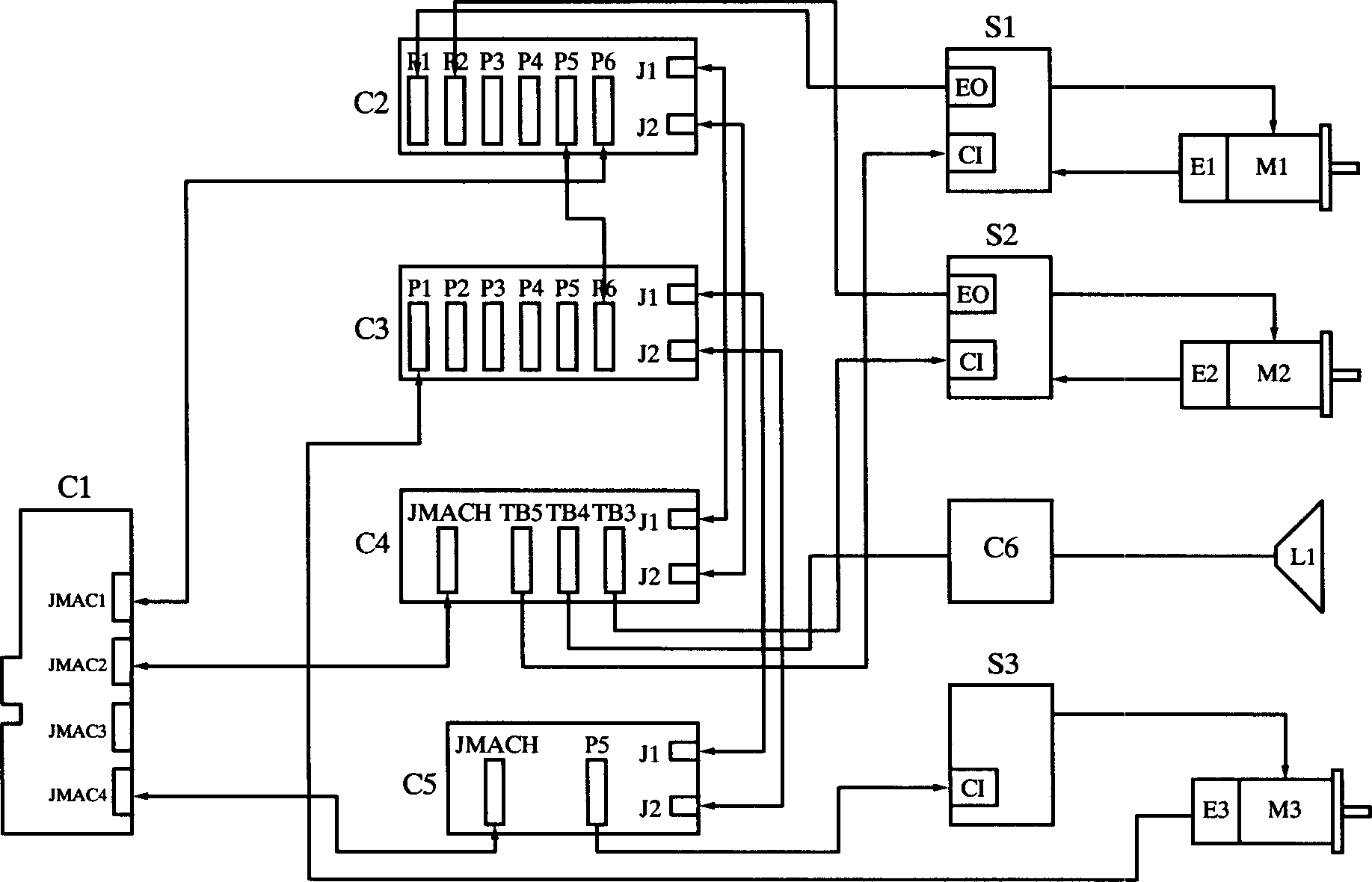

[0024] This control platform passes image 3 The circuit shown realizes the control of servo motors, multi-degree-of-freedom pan-tilt and dimmable lighting of different robots. In the embodiment, an open industrial robot vision platform composed of an industrial robot, an open industrial robot controller, two CCD cameras, a video capture card, and a controllable pan / tilt is built. The industrial computer can use ADVANTECH-610, and the Yaskawa YASKAWA MOTOMAN SK10 robot body as the control object. The two servo packages use the Japanese YASKAWACACR-SR15SZ1SD-Y214 single-axis drive servo package and the DELTA TAU four-axis drive servo package. The former is The voltage-controlled servo package is used to drive the robot’s S, L, U and R joints. The latter is a PWM wave-controlled servo package used to drive the B and T joints of the robot’s wrist. The camera uses The SONY Digital Hyper HAD color camera and video capture card use PCI bus OK-C80 / M capture card, and the pan / tilt uses Y30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com