Inversely feeding ammonium chloride producing process in serial system

A technology of ammonium chloride and reverse feed, applied in the direction of ammonium halide, etc., can solve the problems of easy to produce defective products, the quality of ammonium chloride is average, and the inability to produce refined ammonium, so as to achieve the effect of increasing production and improving the quality of agricultural ammonium products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

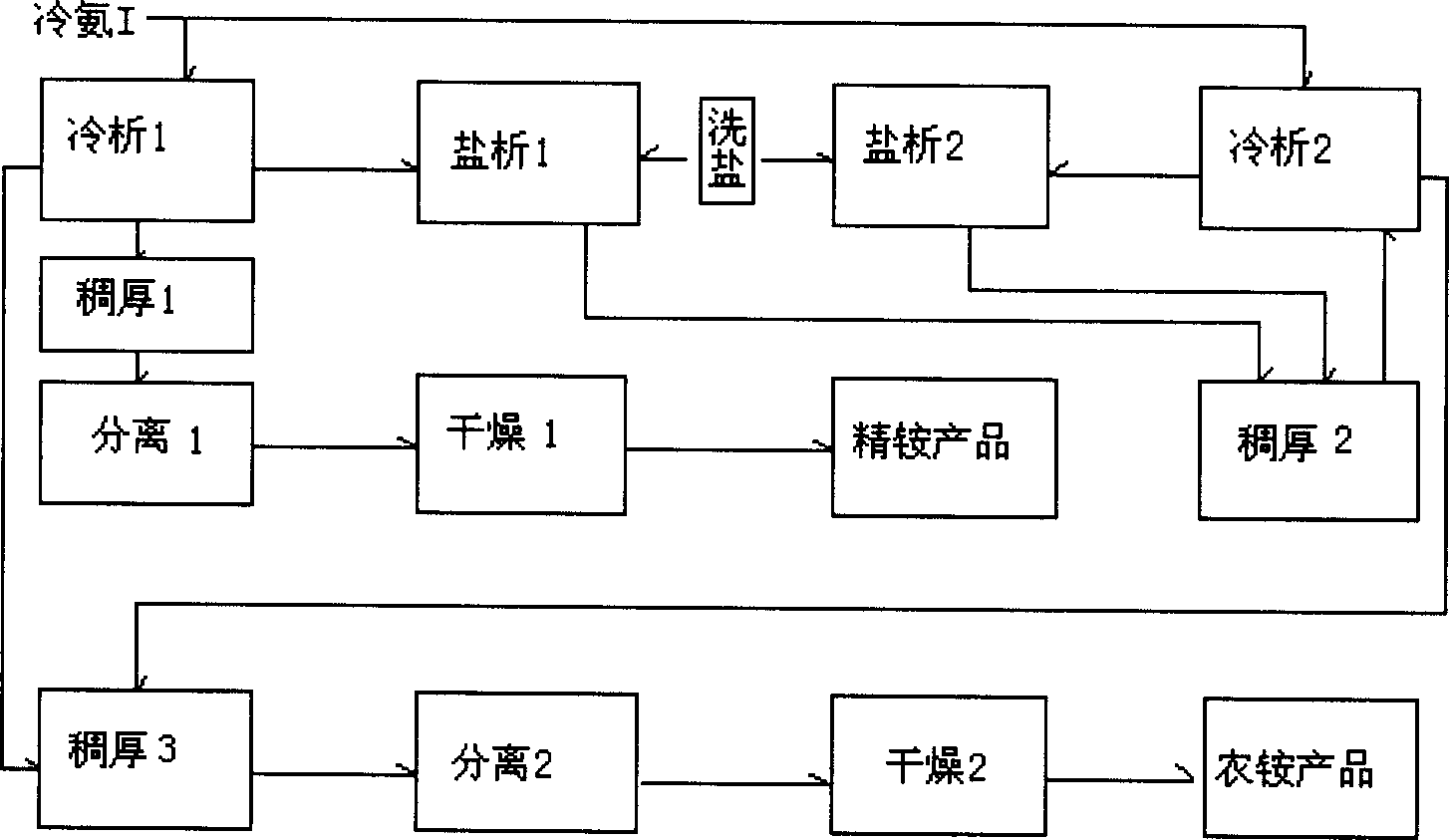

Image

Examples

Embodiment 1

[0009] Send the cold ammonia I mother liquor into two cold crystallizers respectively and cool down to 7°C to precipitate ammonium chloride crystallization through cold analysis, and then take out the solid-liquid apparent volume ratio of 20% in the first cold crystallizer. The slurry is sent into the first thickener for thickening until the solid-liquid apparent volume ratio is 70%, and the thickened crystal slurry can be separated into solid-liquid 1 and dried 1 to obtain refined ammonium products; The clear liquid overflowed from the two cold crystallizers is sent to two salting crystallizers for salting out and mixing. The sodium ion concentration in the mixed liquid is 75tt. Under the action of salting out, the mixed liquid further precipitates ammonium chloride crystals , and then the magma with a solid-liquid apparent volume ratio of 35% in the two crystallizers is sent to the second thickener to be thickened until the solid-liquid apparent volume ratio is 70%, and then ...

Embodiment 2

[0011] Send the cold ammonia I mother liquor into two cold crystallizers respectively, and then cool down to 12°C to precipitate ammonium chloride crystals through cold analysis, and then take out all the solid-liquid apparent volume ratios of 15% in the first cold crystallizer. The magma is sent into the first thickener for thickening until the solid-liquid apparent volume ratio is 70%, and the thickened magma can be separated into solid-liquid 1 and dried 1 to obtain refined ammonium products; The salt and the clear liquid overflowed from the two cold crystallizers are respectively sent to two salting crystallizers for salting out and mixing. The sodium ion concentration in the mixed liquid is 72tt. Under the action of salting out, the mixed liquid further precipitates ammonium chloride crystallization, and then the magma that the solid-liquid apparent volume ratio of taking out in the two crystallizers is 30% is sent into the second thickener together to be thickened until t...

Embodiment 3

[0013] Send the cold ammonia I mother liquor into two cold crystallizers respectively and cool down to 9° C. to precipitate ammonium chloride crystallization, and then take out the solid-liquid apparent volume ratio of 30% in the first cold crystallizer. The slurry is sent into the first thickener for thickening until the solid-liquid apparent volume ratio is 60%, and the thickened crystal slurry can be separated into solid-liquid 1 and dried 1 to produce refined ammonium products; The clear liquid overflowed from the two cold crystallizers is sent to two salting crystallizers for salting out and mixing. The sodium ion concentration in the mixed liquid is 74tt. Under the action of salting out, the mixed liquid further precipitates ammonium chloride crystals , and then the magma with a solid-liquid apparent volume ratio of 45% in the two crystallizers is sent to the second thickener to be thickened until the solid-liquid apparent volume ratio is 60%, and then sent to the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com