Method for prepn. of electrode catalyst contg. platinum carried on carbon nanometer tube

A carbon nanotube, platinum electrode technology, applied in the field of proton exchange membrane fuel cell and direct methanol proton exchange membrane fuel cell, electrode catalyst preparation field, can solve the problem of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

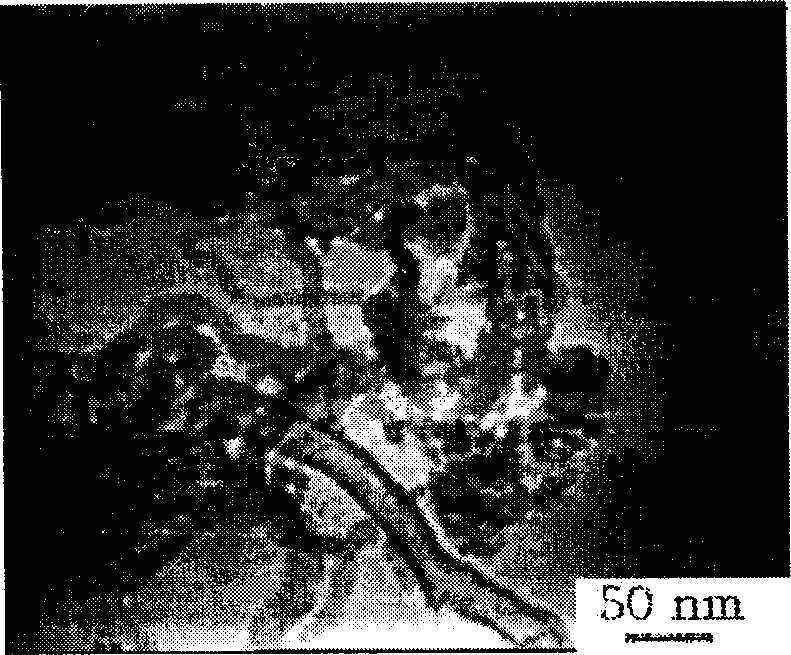

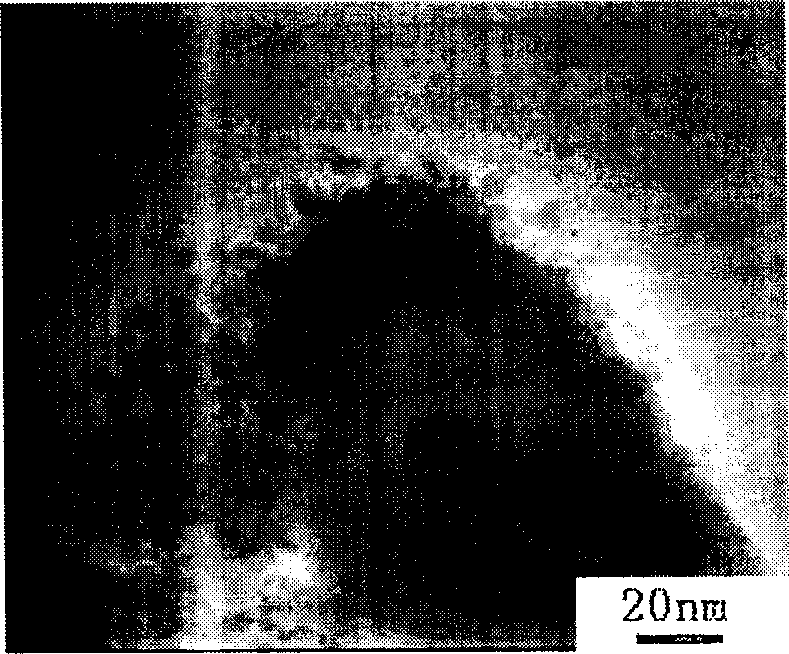

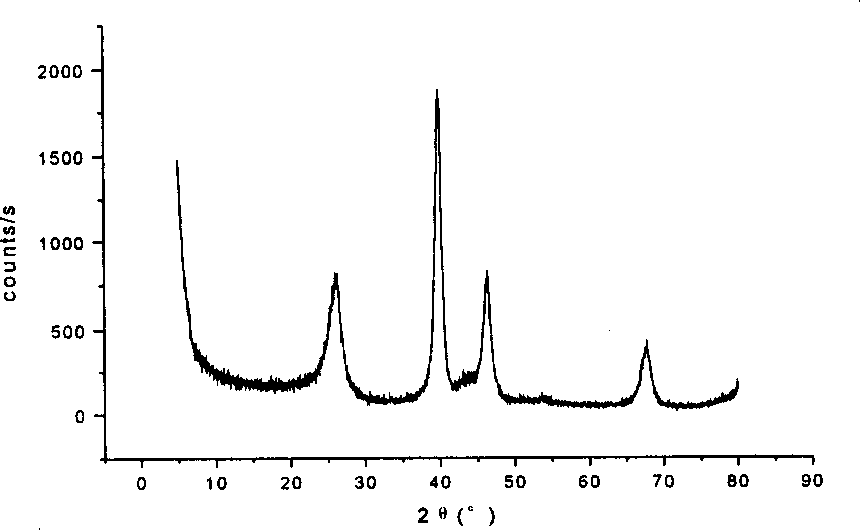

Image

Examples

Embodiment 1

[0028] 1. Activation treatment of carbon nanotubes (provided by the Department of Chemical Engineering, Tsinghua University)

[0029] (1) Water washing: put carbon nanotubes into a round bottom flask, moisten with absolute ethanol, then add a certain amount of double distilled water, heat to boil, reflux for 1 hour, filter, and dry at 80°C for 2 hours to obtain water-washed activated carbon nanotube samples.

[0030] (2) pickling: soak the water-washed activated carbon nanotube sample with 10% hydrochloric acid for 10 hours, reflux for 1h, filter, and wash with water until there is no Cl - Dry at 80°C for 2 hours.

[0031] 2. Preparation of Pt / CNTs catalyst

[0032] (1) Weigh 1.5068 grams of activated carbon nanotubes, add them to a round bottom flask, add a certain amount of absolute ethanol dropwise to moisten, then add 80 mL of double distilled water, and stir for 5 minutes;

[0033] (2) Add the prepared chloroplatinic acid solution (1 gram of chloroplatinic acid dissolv...

Embodiment 2

[0037] 1. Activation treatment of carbon nanotubes (provided by the Department of Chemical Engineering, Tsinghua University)

[0038] (1) Water washing: put carbon nanotubes into a round bottom flask, moisten with absolute ethanol, then add a certain amount of double distilled water, heat to boil, reflux for 1 hour, filter, and dry at 80°C for 2 hours to obtain water-washed activated carbon nanotubes sample.

[0039] (2) Pickling: soak the water-washed activated carbon nanotube sample with 10% hydrochloric acid for 10 h, reflux for 1 h, filter, and wash with water until there is no Cl - Dry at 80°C for 2 hours.

[0040] 2. Preparation of Pt / CNTs catalyst

[0041] (1) Weigh 0.5651 g of activated carbon nanotubes and place them in a round bottom flask, add an appropriate amount of absolute ethanol dropwise to moisten, add 100 mL of double distilled water, and stir for 5 min;

[0042] (2) Add the prepared chloroplatinic acid solution (1 gram of chloroplatinic acid dissolved in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com