Metal corrosion inhibitor

A metal corrosion inhibitor and technology of corrosion inhibitor, applied in the field of metal corrosion prevention, can solve problems such as poor corrosion inhibition rate, and achieve the effects of increasing the protection area, good corrosion inhibition rate and tight arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

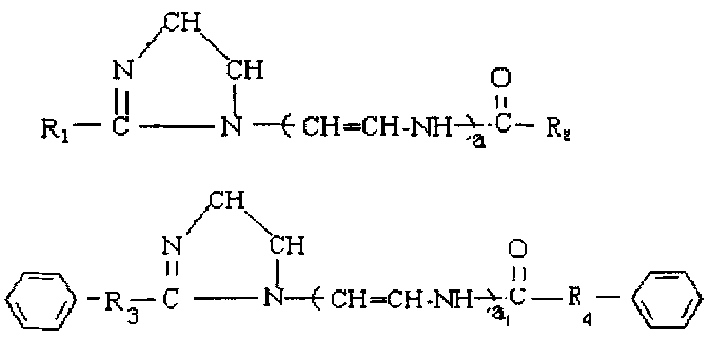

Method used

Image

Examples

Embodiment 1

[0033] The composition of corrosion inhibitor A of the present invention: imidazoline amide with aromatic ring: 50%; straight chain imidazoline amide: 20%; thiourea: 2.5%; propynyl alcohol: 2.5%, xylene: 25%.

[0034] Experimental conditions: 1000ppmHCl+1000ppmNaCl+160ppmH 2 S, static soaking 6h 90℃

[0035] It can be seen from Table 1 that the corrosion inhibitor A exhibits a high corrosion inhibition rate in the range of pH value from 1.86 to 7.5, which can meet the corrosion protection requirements of the condensation cooling system equipment at the top of the atmospheric and vacuum unit.

Embodiment 2

[0037] The corrosion inhibitor B of the present invention consists of: imidazoline amide with aromatic ring: 20%; straight chain imidazoline amide: 50%; thiamine: 2.5%; propynyl alcohol: 2.5%, gasoline: 25%.

[0038] Experimental conditions: 1000ppmHCl+1000ppmNaCl+160ppmH 2 S, static soaking 6h 90℃

[0039]It can be seen from Table 2 that the corrosion inhibitor B exhibits a high corrosion inhibition rate in the range of pH value from 1.86 to 7.5, which can meet the corrosion protection requirements of the condensation cooling system equipment at the top of the atmospheric and vacuum unit.

Embodiment 3

[0041] The corrosion inhibitor C of the present invention consists of: imidazoline amide with aromatic ring: 30%; straight-chain imidazoline amide: 30%; thiourea: 2.5%; propynyl alcohol: 2.5% and diesel oil: 35%.

[0042] Experimental conditions: 1000ppmHCl+1000ppmNaCl+160ppmH 2 S, static soaking 6h 90℃

[0043] It can be seen from Table 3 that the corrosion inhibitor C exhibits a high corrosion inhibition rate in the range of pH value from 1.86 to 7.5, which can meet the corrosion protection requirements of the condensation cooling system equipment at the top of the atmospheric and vacuum unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com