Process for extracting alliin from fresh garlic

A production process, the technology of alliin, which is applied in the production process field of extracting alliin from fresh garlic, and can solve the problems such as difficulty in extracting alliin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

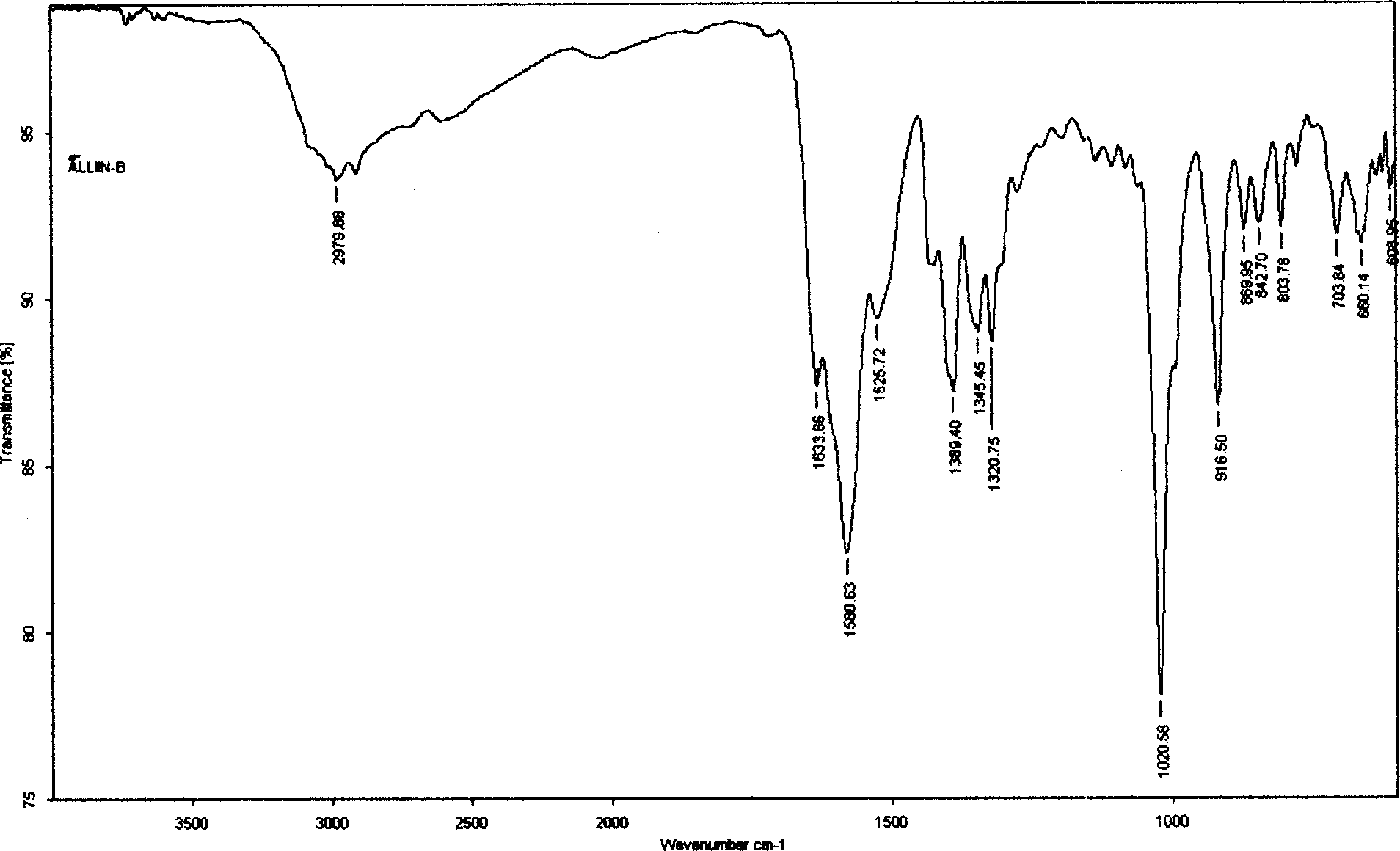

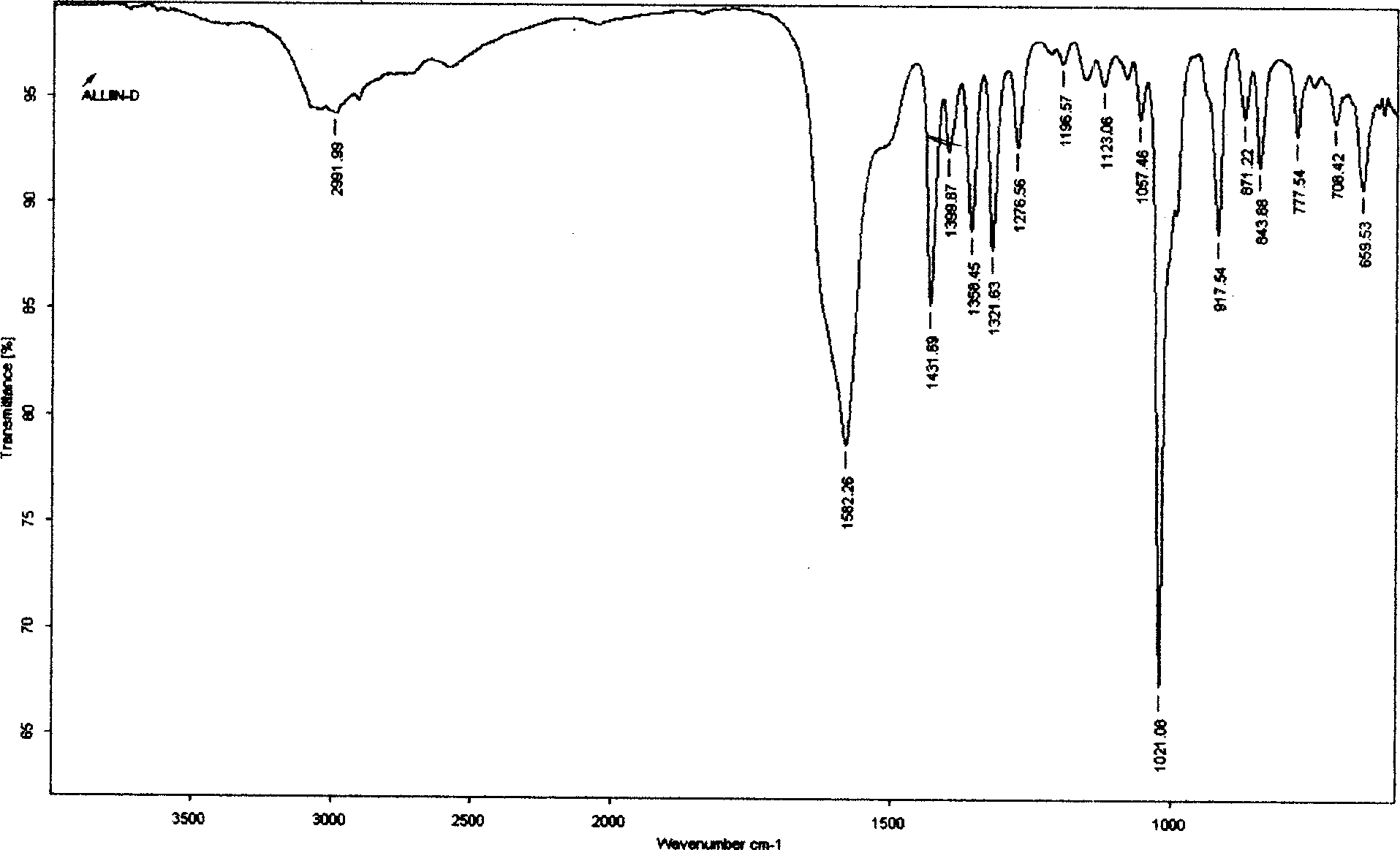

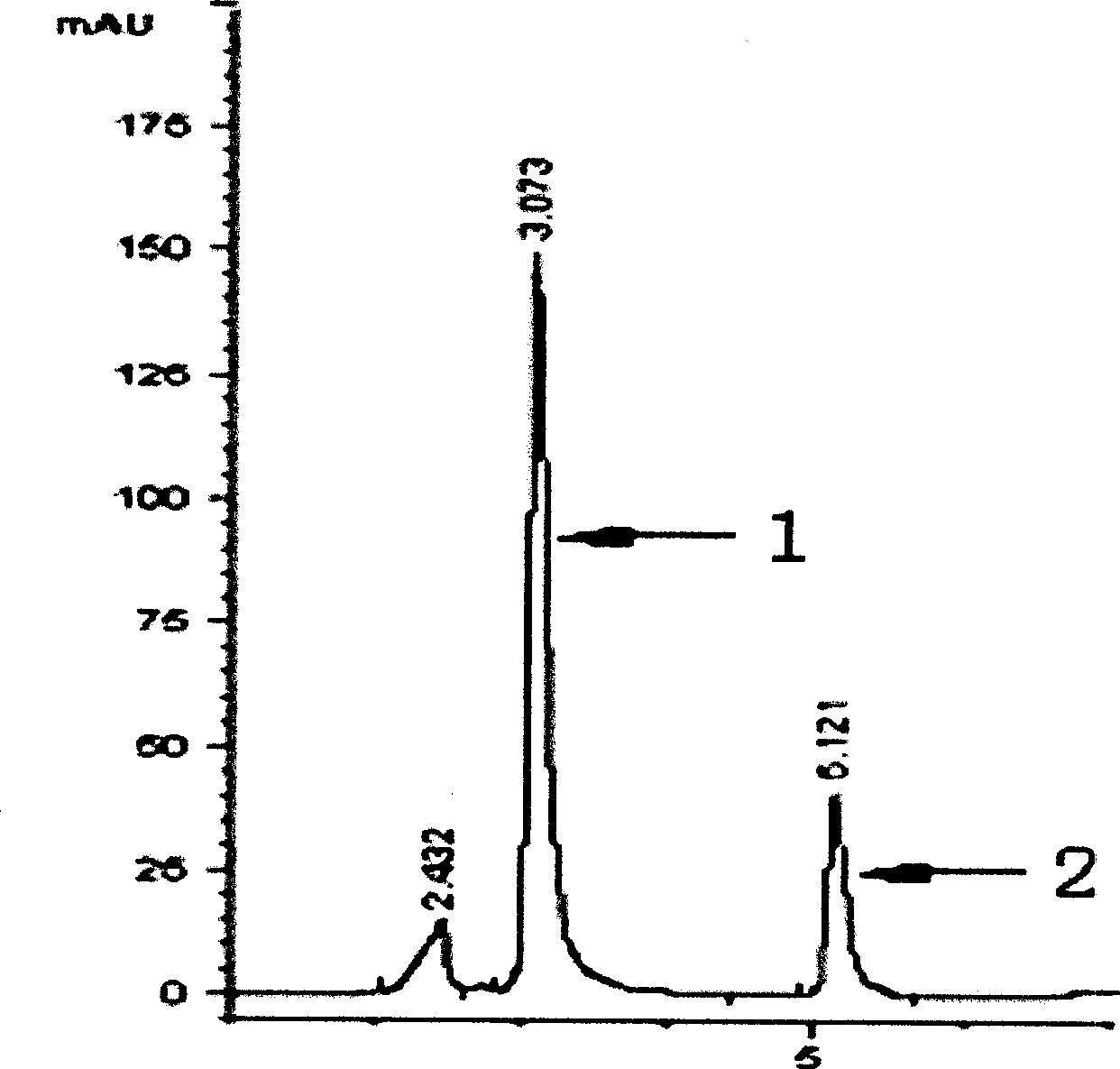

Image

Examples

Embodiment

[0026] Embodiment, carry out according to the following steps:

[0027] The first step is pretreatment: microwave the garlic cloves to kill enzymes until the garlic cloves turn from white to translucent; it is best to put the garlic cloves in the microwave for 2 minutes, 3.5 minutes or 5 minutes, and the microwave frequency is preferably 2540 ±50MHz, the output microwave power is preferably 20KW. Before microwave enzyme treatment, it is best to remove the garlic cloves and wash and drain.

[0028] The second step is to extract organic matter: Grind the garlic cloves after microwave treatment into 100 to 200 mesh garlic pulp, add ethanol or alcohol, use an ethanol hydrometer to control the ethanol concentration of the garlic pulp to 40% to 70%, and stir for 2 to 10 hours , separated to obtain the extract, and concentrated the extract under reduced pressure. It is best to re-extract 3 or 5 times by weight. It is best to use the multi-effect decompression film concentration me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com