Method for producing short colored polyester staple

A production method and staple fiber technology, which is applied in the production field of polyester colored staple fibers, can solve the problems of complex dyeing process, large product color difference, serious pollution, etc., and achieve the effect of wide color spectrum, small product color difference and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

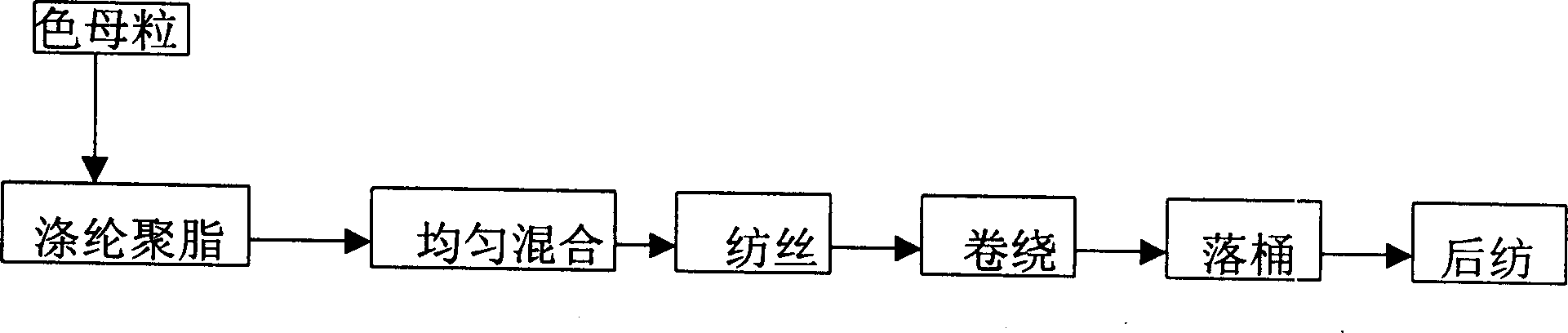

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: produce 1.5D scarlet fiber

[0013] Take 800kg of white polyester polyester raw material and 58kg of bright red masterbatch, put them into the drum through the feeding hopper, mix them evenly, dry for 10 hours, put them into the screw extrusion spinning machine for spinning, wind up and fall into the barrel for post-spinning.

Embodiment 2

[0014] Embodiment 2: produce 1.5D navy blue fiber

[0015] Get green polyester polyester raw material 800kg and dark blue masterbatch 58kg, all the other are with example 1.

Embodiment 3

[0016] Embodiment 3: produce 1.5D light yellow fiber

[0017] Get white polyester polyester raw material 800kg and light yellow masterbatch 25kg, all the other are with example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com