Small ion-decomposing melting furnace

A melting furnace and ion technology, applied in furnaces, incinerators, electric furnace heating and other directions, can solve the problems of difficulty in moving and troublesome processing, and achieve the effects of increasing plasma concentration, decomposition efficiency and ion concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] (Embodiment 1)

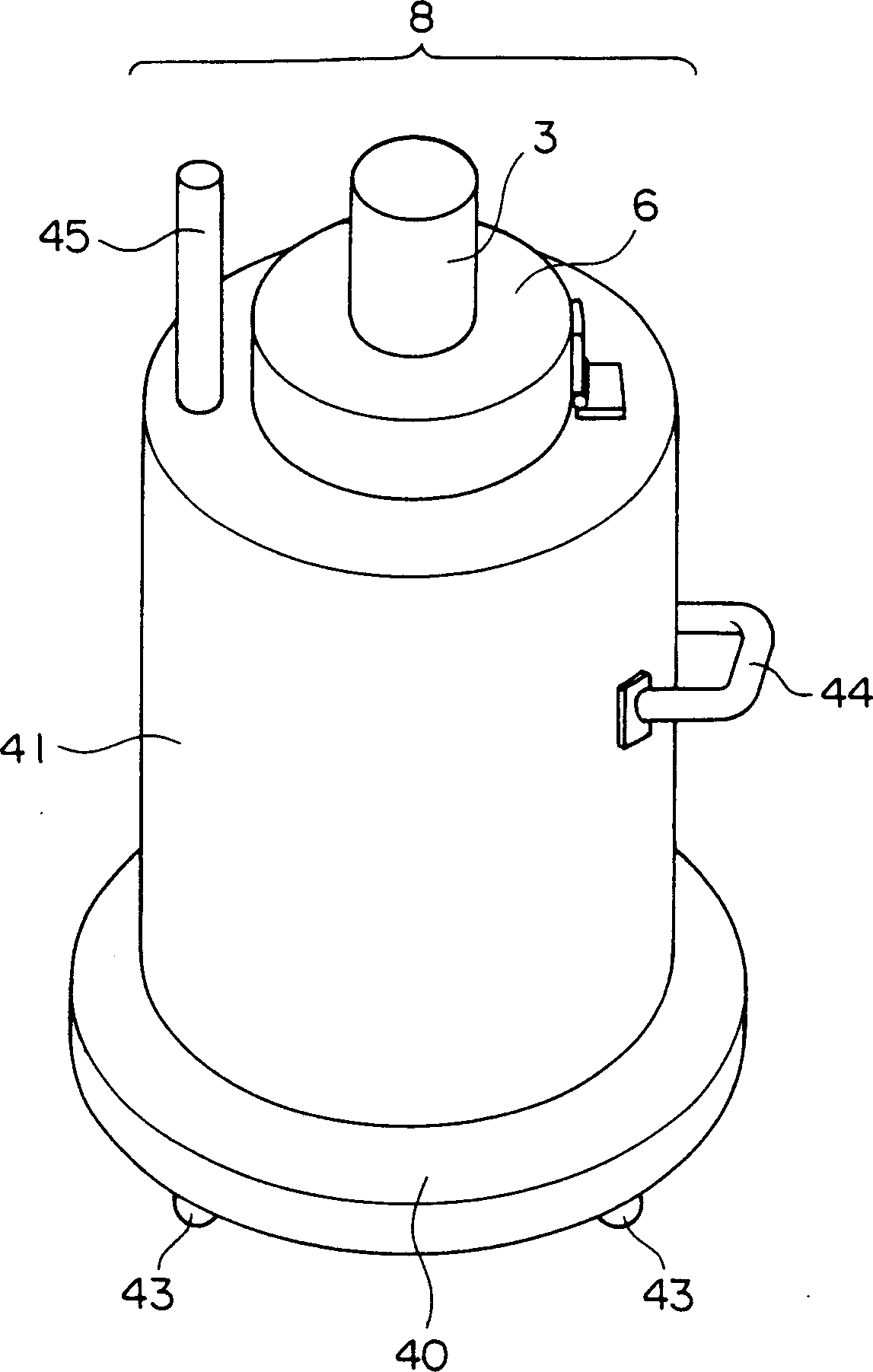

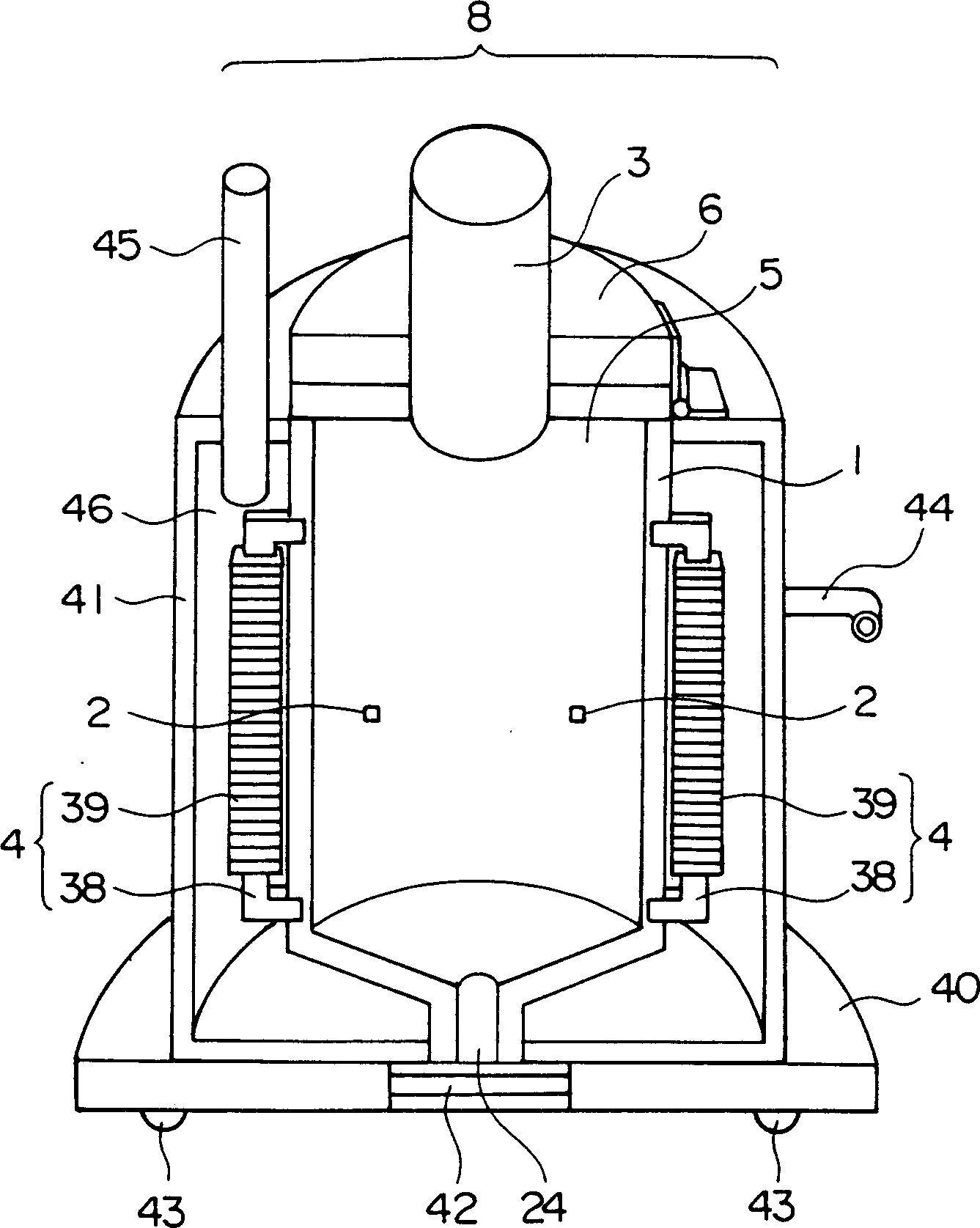

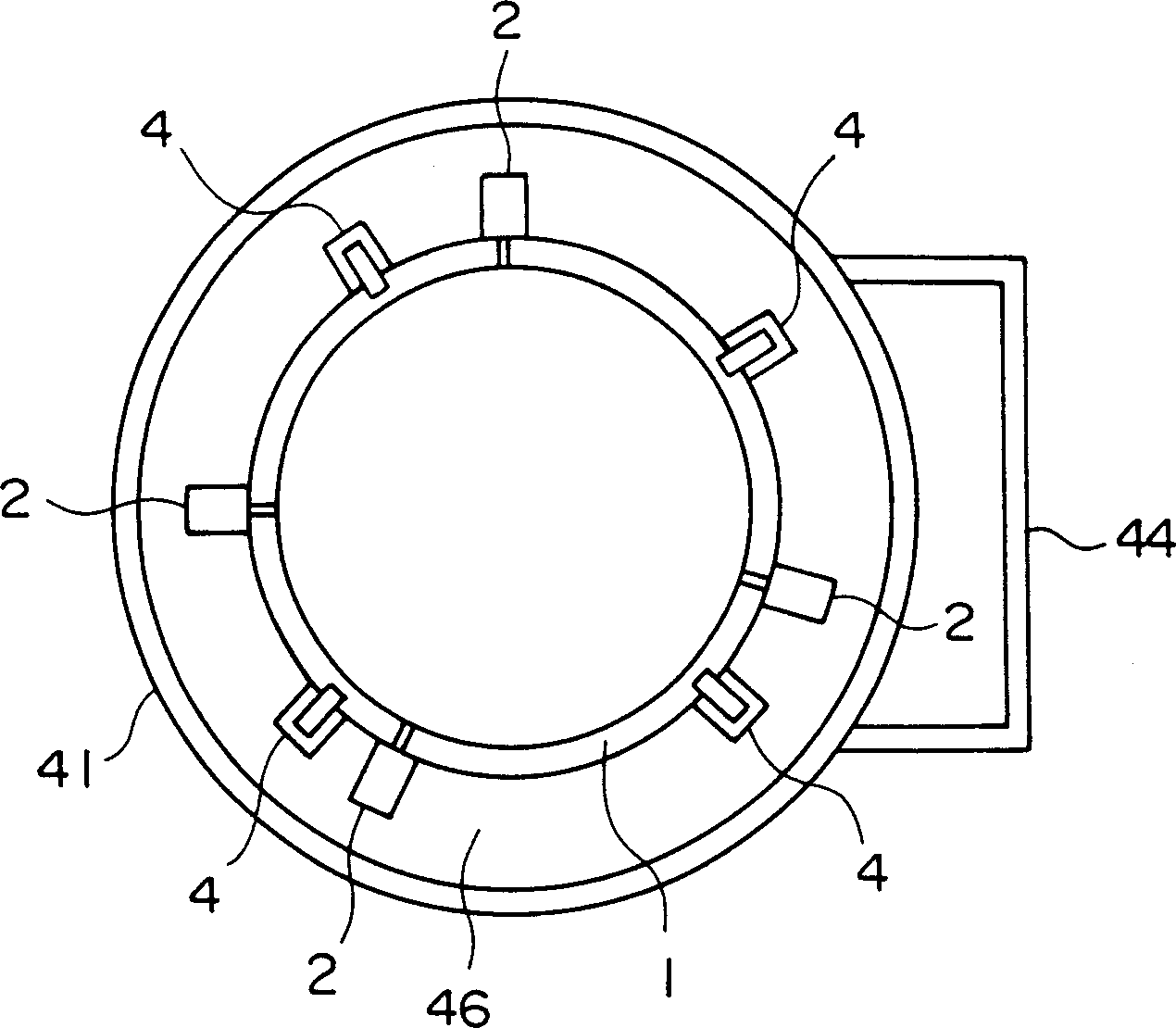

[0020] based on Figure 1 to Figure 8 A first embodiment of the small ion decomposition type melting furnace of the present invention will be described. The small-sized ion decomposition type melting furnace 8 of these figures is that four magnetrons 2 are set on the wall around the incinerator body 1, and ionizers are installed downwards on the cover 6 covering the input port 5 on the top of the incinerator body 1. The flame generator (ion furnace) 3 is provided with six tokamaks 4 on the same incinerator body 1 . The aforementioned four magnetrons 2 are as image 3 The non-facing positions of the walls around the incinerator body 1 are installed as shown, and the aforementioned six tokamak 4 are as follows image 3 As shown, four are set on the periphery of the incinerator body 1, such as Figure 5 As shown, one is respectively arranged on the upper part and the lower part of the incinerator body.

[0021] The furnace wall 20 of the incinerator b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com