Cross thin wall pipe-sinking device for vibration pipe-sinking pile-dilling machine and pile-filling method thereof

A technology of immersed cast-in-place piles and immersed pipe piles is applied in sheet pile wall, building, infrastructure engineering and other directions, which can solve the problems of increasing project cost, low bearing capacity, small side friction resistance, etc., so as to reduce project cost and improve The effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

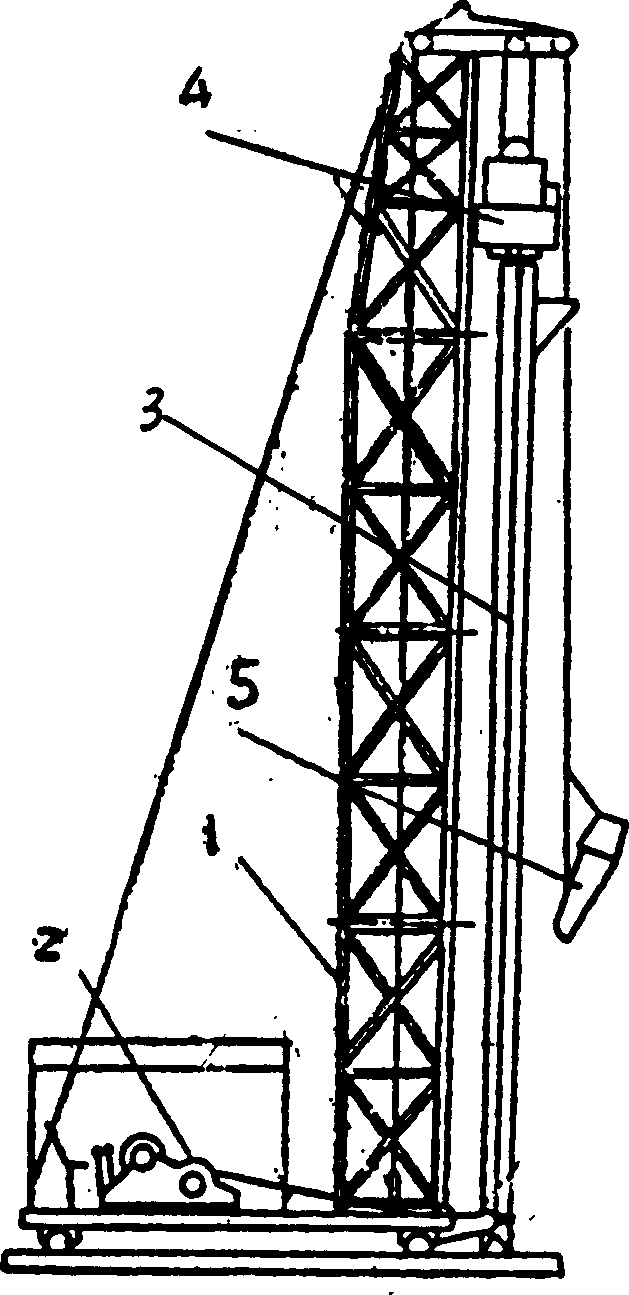

[0021] Depend on figure 1 It can be seen that the vibrating pipe sinking pile machine is composed of five parts: a frame 1, a hoist 2, an immersed pipe 3, a vibrating hammer 4 and a bucket 5. Among them, the frame 1 plays the role of supporting the hoist, the sinking tube with the valve pile tip, the vibrating hammer and the bucket; the hoist 2 is the power equipment for the pile sinking tube and the bucket to lift; Under the action of the vibrating hammer, the pipe 3 can pass through the general cohesive soil, silt soil, silty soil, silt, loose to medium-density sandy soil and artificial filling soil, and then pour concrete, and pull out the pile while vibrating The equipment; the vibratory hammer 4 has the dual functions of sinking the pipe and pulling the pile; the concrete is poured into the pile pipe through the bucket 5.

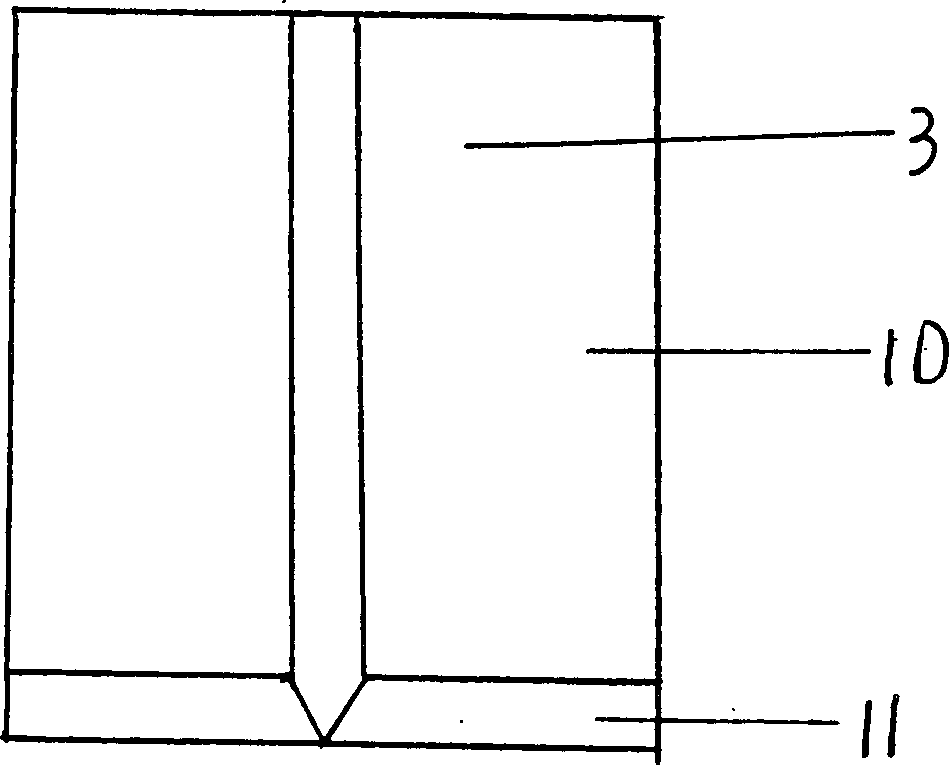

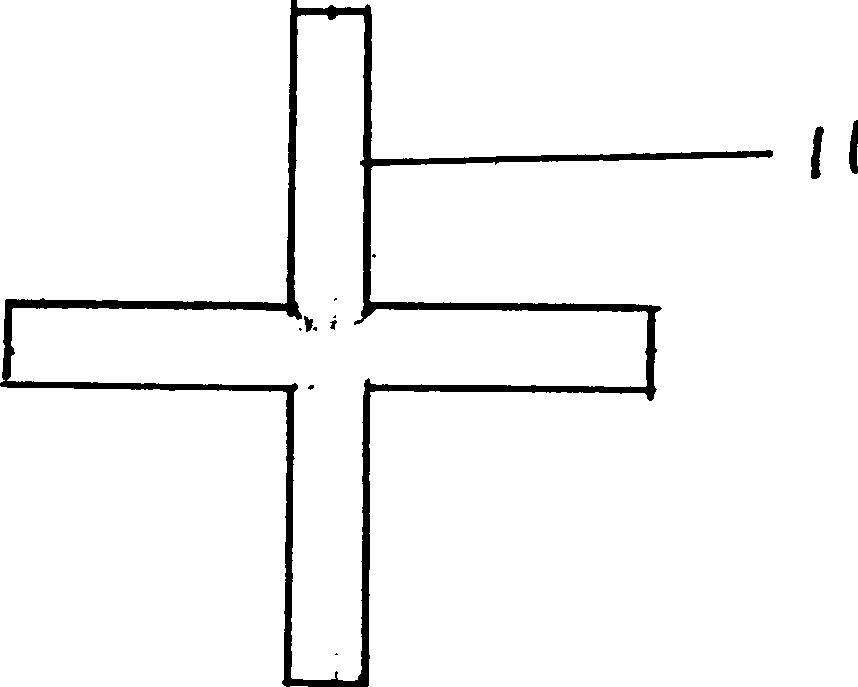

[0022] Depend on figure 2 , image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com