Shape measurer with adjustable image magnifying power in two axes

A technology of magnification and measuring device, applied in the direction of measuring device, instrument, etc., can solve the problems of difficulty, no use value, shortened field of view, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0017] In order to improve the problem of uneven resolution in the direction of projected light in the prior art, the present invention provides a shape measuring device for biaxially modulating image magnification, adopting an optical system to provide a biaxially modulating image magnification The unique shape measurement device adopts the characteristics of the telecentric optical structure of the optical system to make the resolution of the far and near uniform.

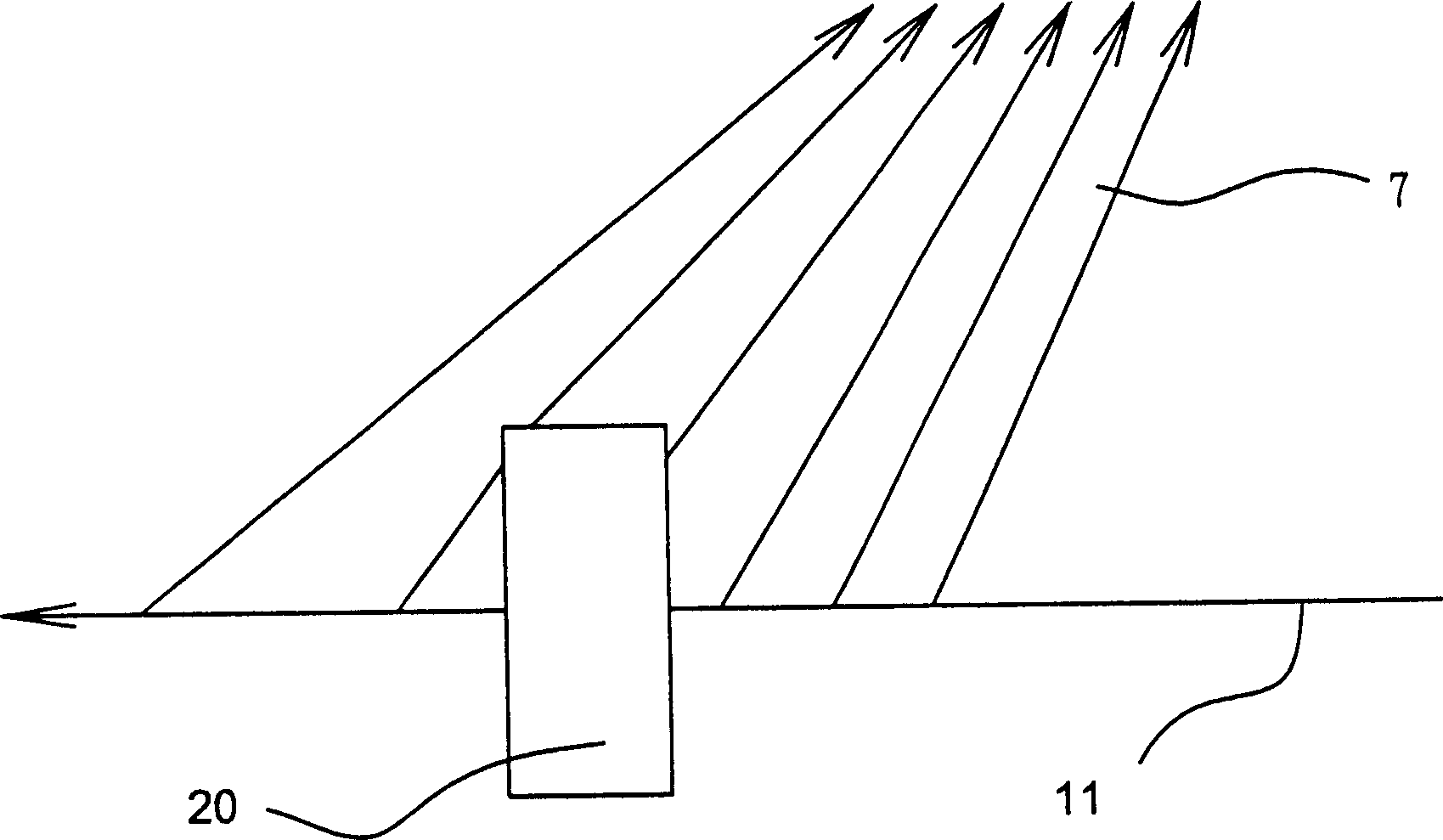

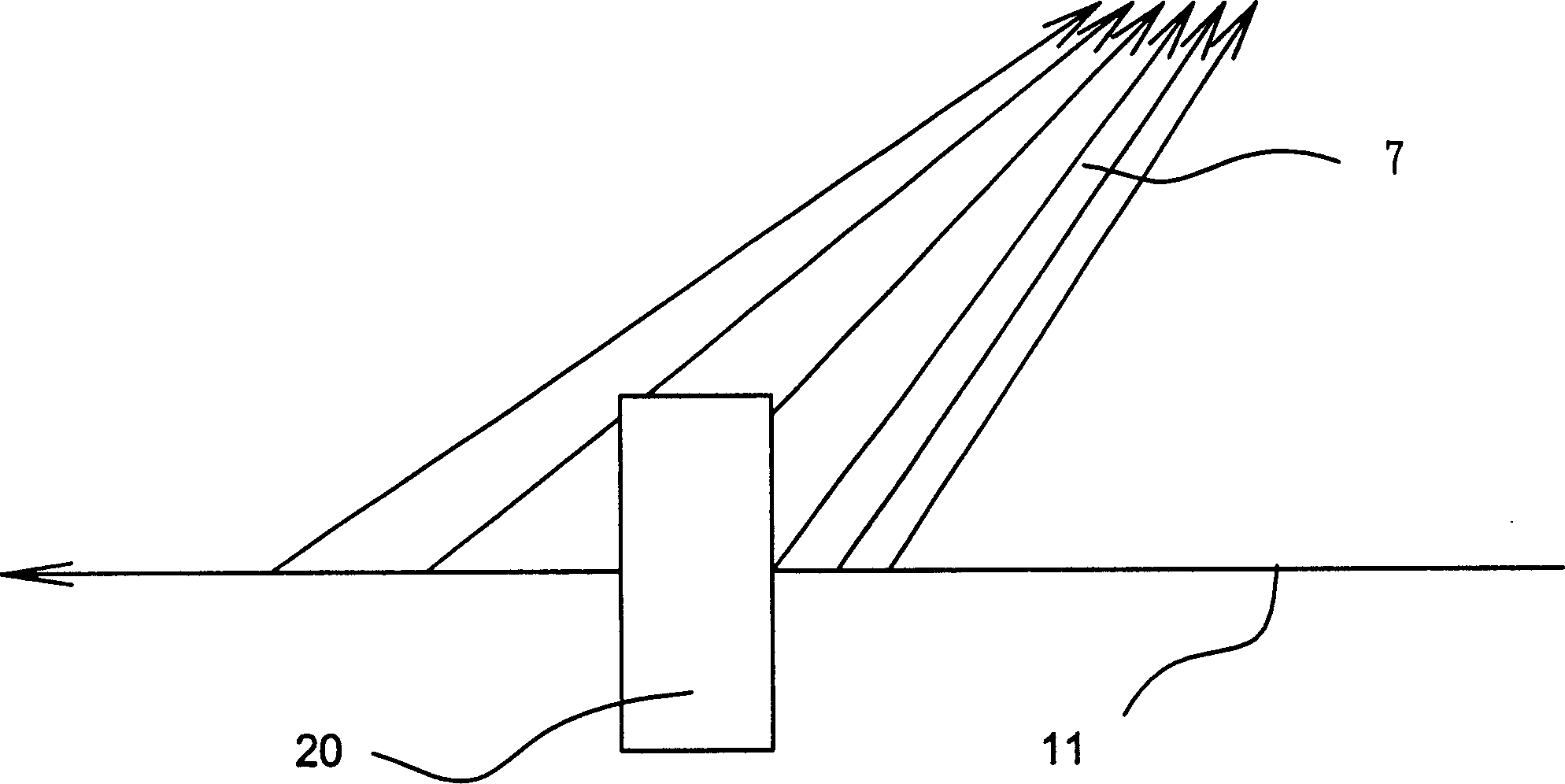

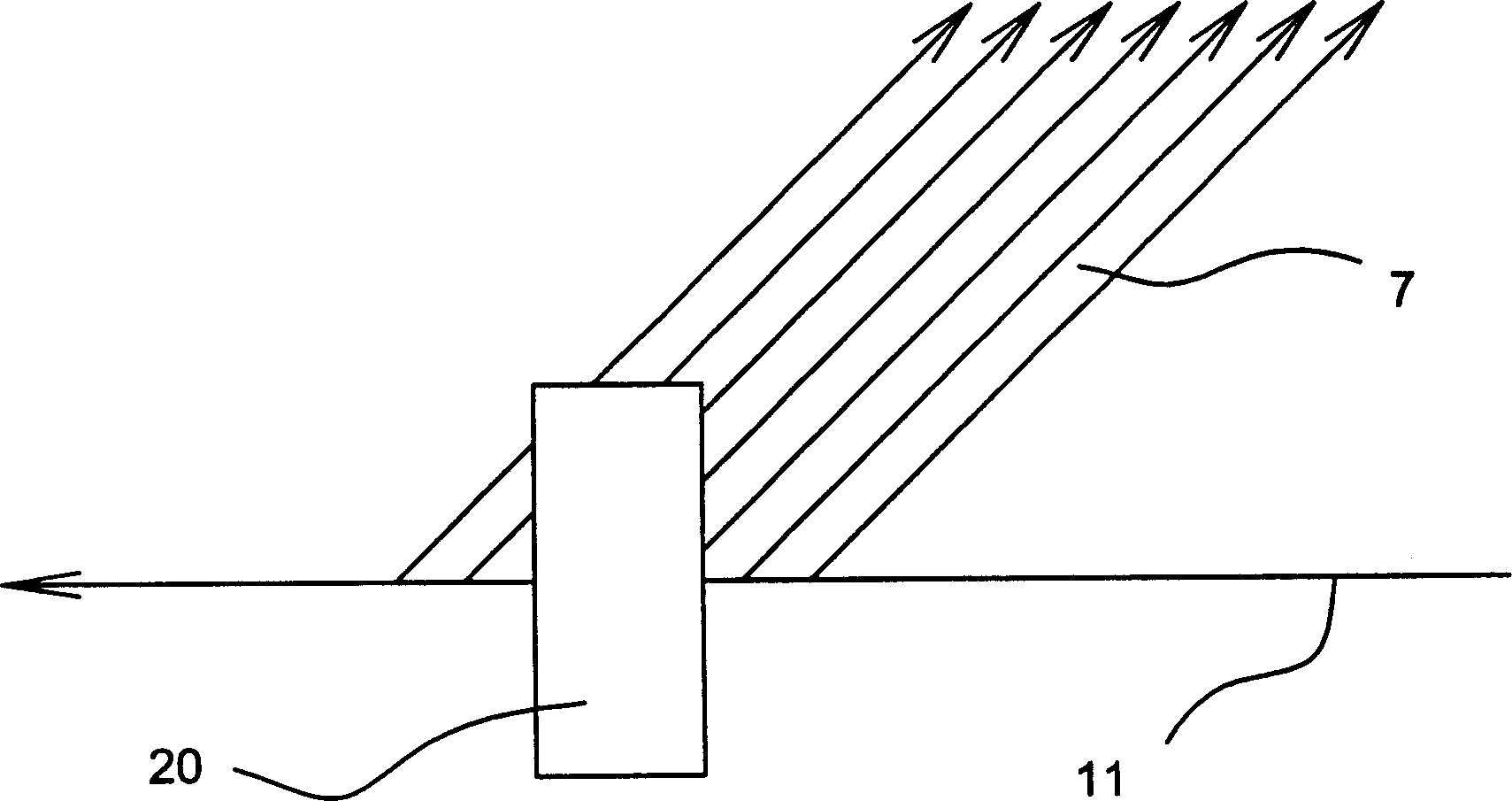

[0018] Such as Figure 4 As shown, it is a perspective view of the shape measuring device of the present invention. A light source 10 is used to project a plane light (or line beam) onto the surface of an object 20, and the intersection line (or point) 21 with the surface of the object 20 can be calculated using the principle of triangulation distance measurement. its three-dimensional coordinates. Firstly, the light 21 is reflected to a curved mirror 40 and then reflected into a cylindrical lens group 50 , and ...

no. 2 example

[0020] Such as Image 6 As shown, it is another embodiment of the present invention, adopting a telecentric cylindrical lens group 40B (made up of a cylindrical lens 401B and a plane reflector 402B) to replace the curved reflector 40A; providing a light source 10 to form a projection light plane 11 to the object 20, intersecting on the object 20 as a point or line, from the optical path 30 through the cylindrical lens 42 and the plane reflector 40A, and then through the cylindrical lens group 50 (concave cylindrical lens 51, convex cylindrical lens 52) , is imaged on the CCD 62 by the imaging objective lens group 61 (lens). In order to allow the far and near resolution to be uniform, the focal length of the cylindrical lens 401B is close to the optical path distance between it and the imaging objective lens group 61 (lens), and the aperture is located on the imaging objective lens group 61, so that a telecentric optical framework is formed, and the optical coupling assembly 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com