P-ZnO thin film and preparation thereof

A thin-film, p-zno technology, used in semiconductor/solid-state device manufacturing, ion implantation plating, coating, etc., can solve the problem of poor particle uniformity on the surface of ZnO, unsatisfactory doping effect, and unsatisfactory doping effect, etc. problem, to achieve the effect of abundant raw materials, low price and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

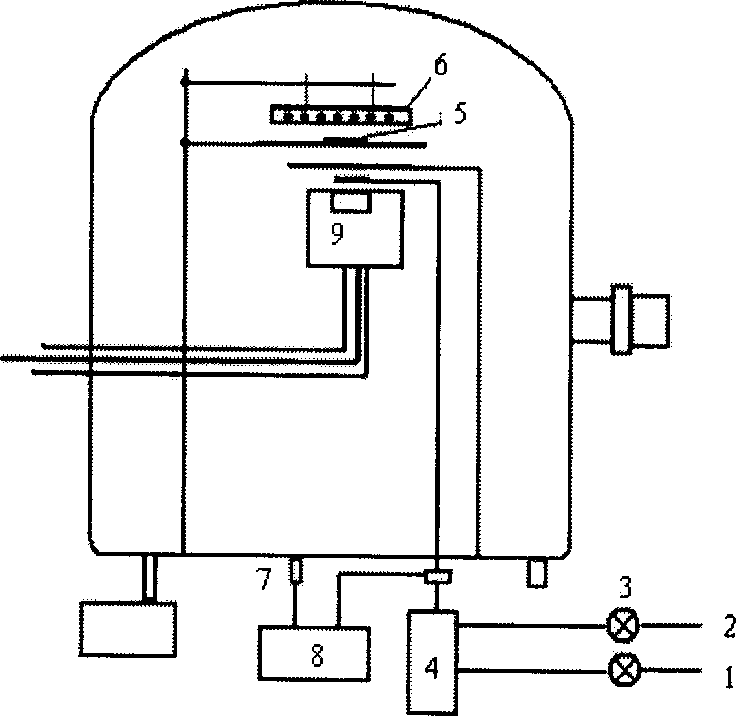

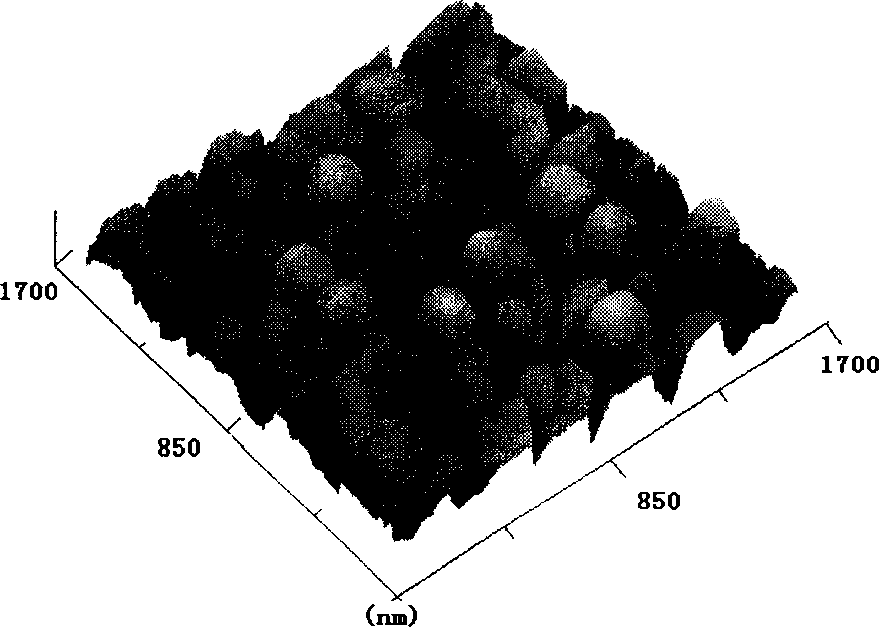

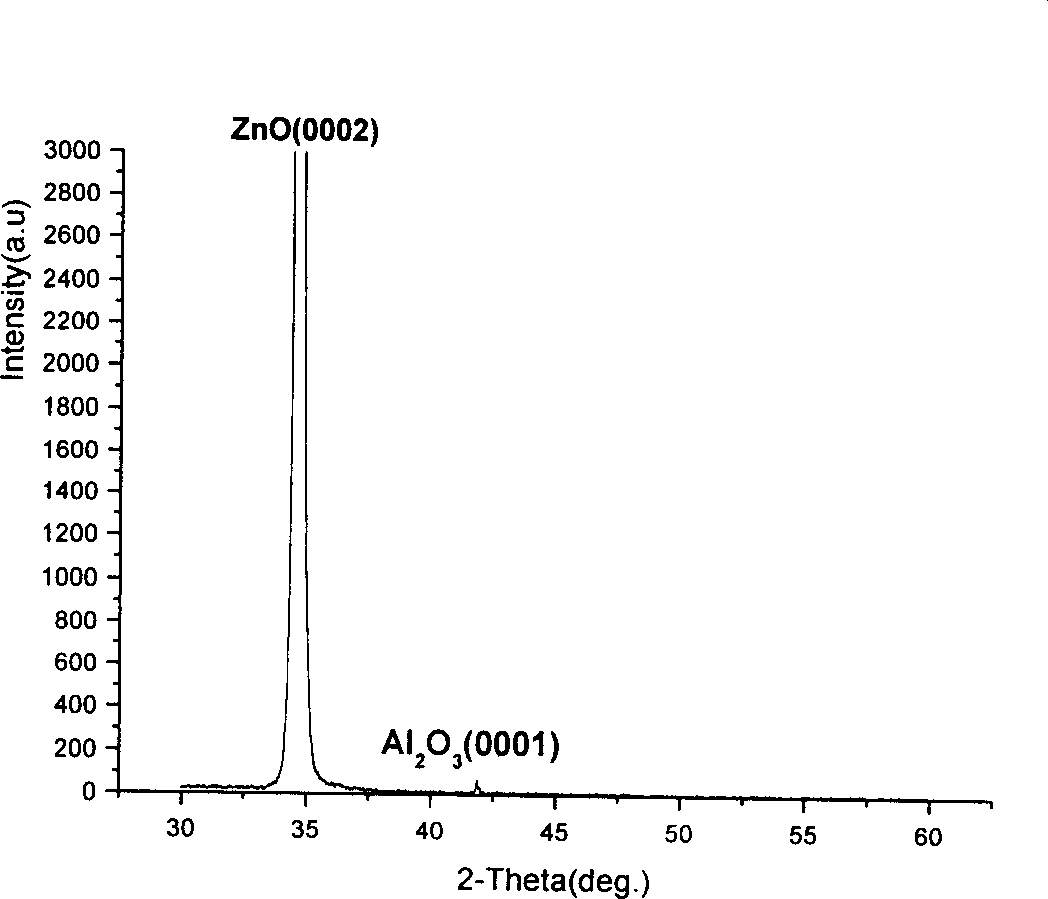

[0014] Refer to the following figure 1 , the preparation method of the p-ZnO thin film of the present invention is further illustrated by examples. First, the substrate is surface-cleaned and placed on the sample holder 5 in the reaction chamber. The substrate to be deposited is placed facing down to effectively prevent granular impurities from contaminating the substrate. The vacuum degree of the reaction chamber is pumped to 1×10 -3 Pa, use a heater to heat the substrate, and the substrate temperature is controlled at 550°C; the sputtering gas is high-purity NH 3 (above 99.99%) and high-purity O 2 (more than 99.99%), the two-way gas enters the buffer chamber 4 through the inlet pipe 1 and 2, and is introduced into the vacuum chamber after the buffer chamber is fully mixed. The pressure in the vacuum chamber is controlled by the automatic pressure controller 8, and the pressure is 3Pa. NH 3 with O 2 The partial pressure ratio can be adjusted through the flow meter 3 accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com