Surface aeration multiphase contact stirring equipment

A surface aeration and stirring device technology, which is applied to mixers with rotating stirring devices, transportation, packaging, dissolution, etc., can solve the problems of lack of aeration efficiency, achieve enhanced aeration capacity, enhanced mass transfer effect, absorption The effect of strong energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

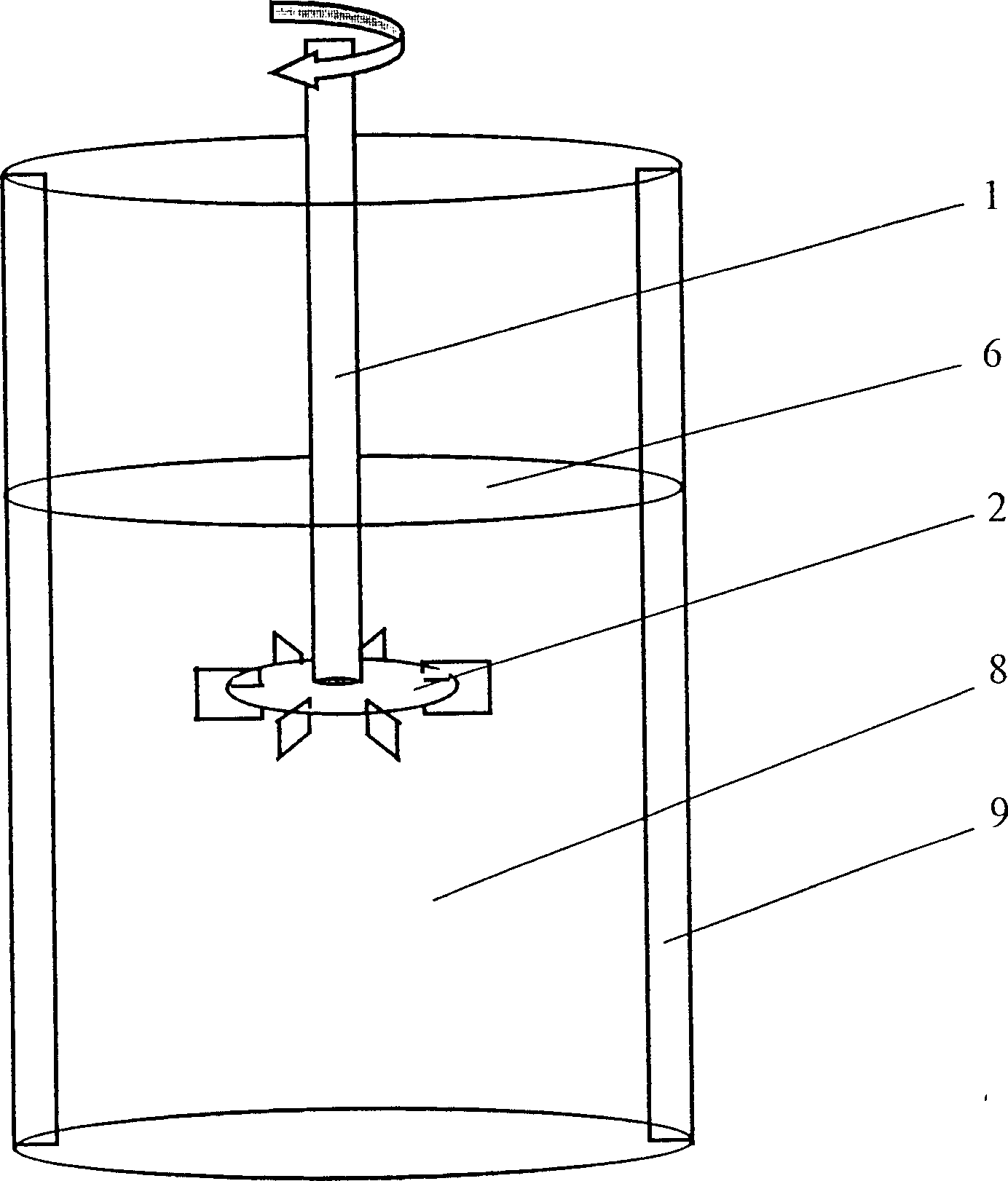

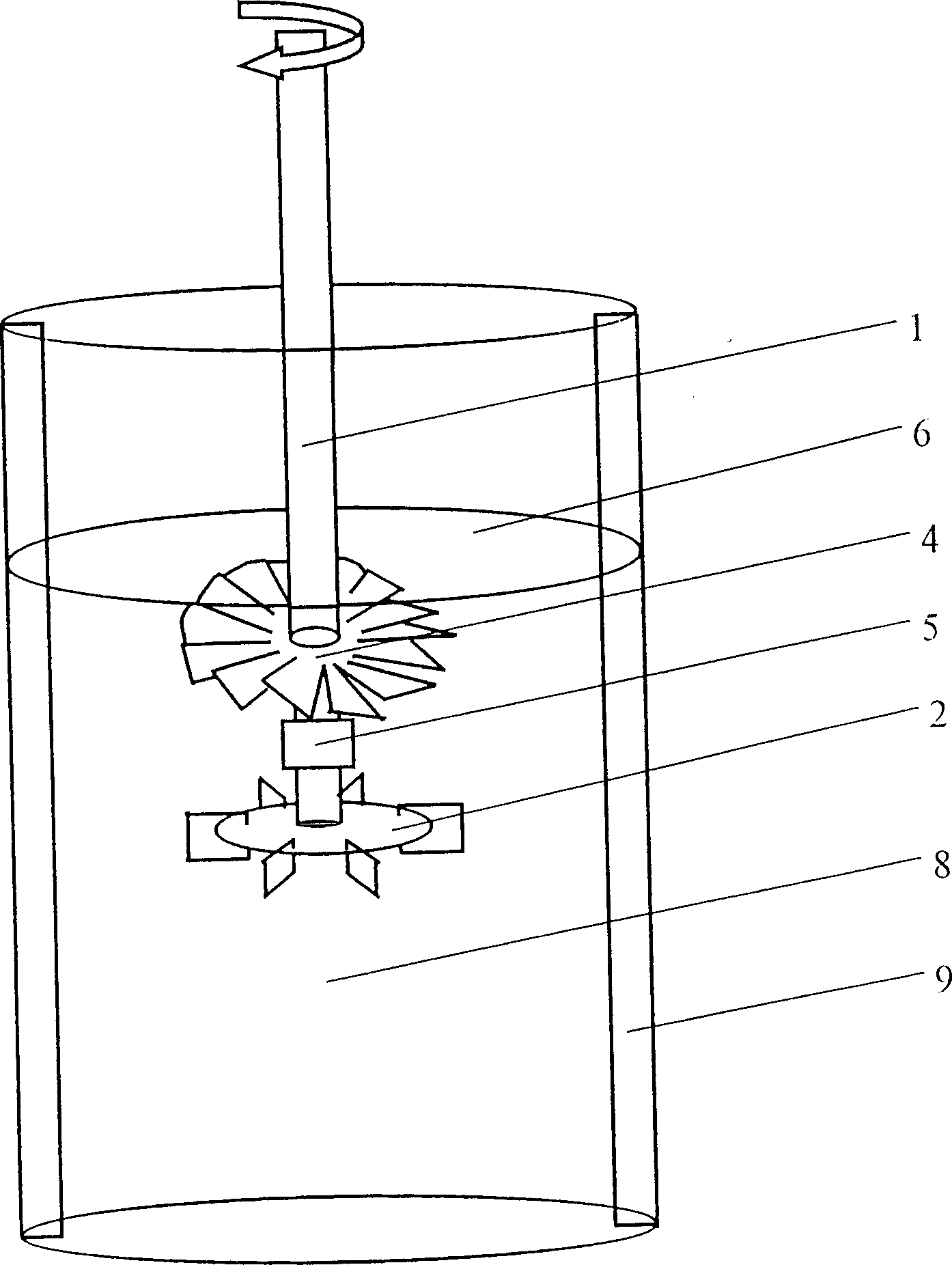

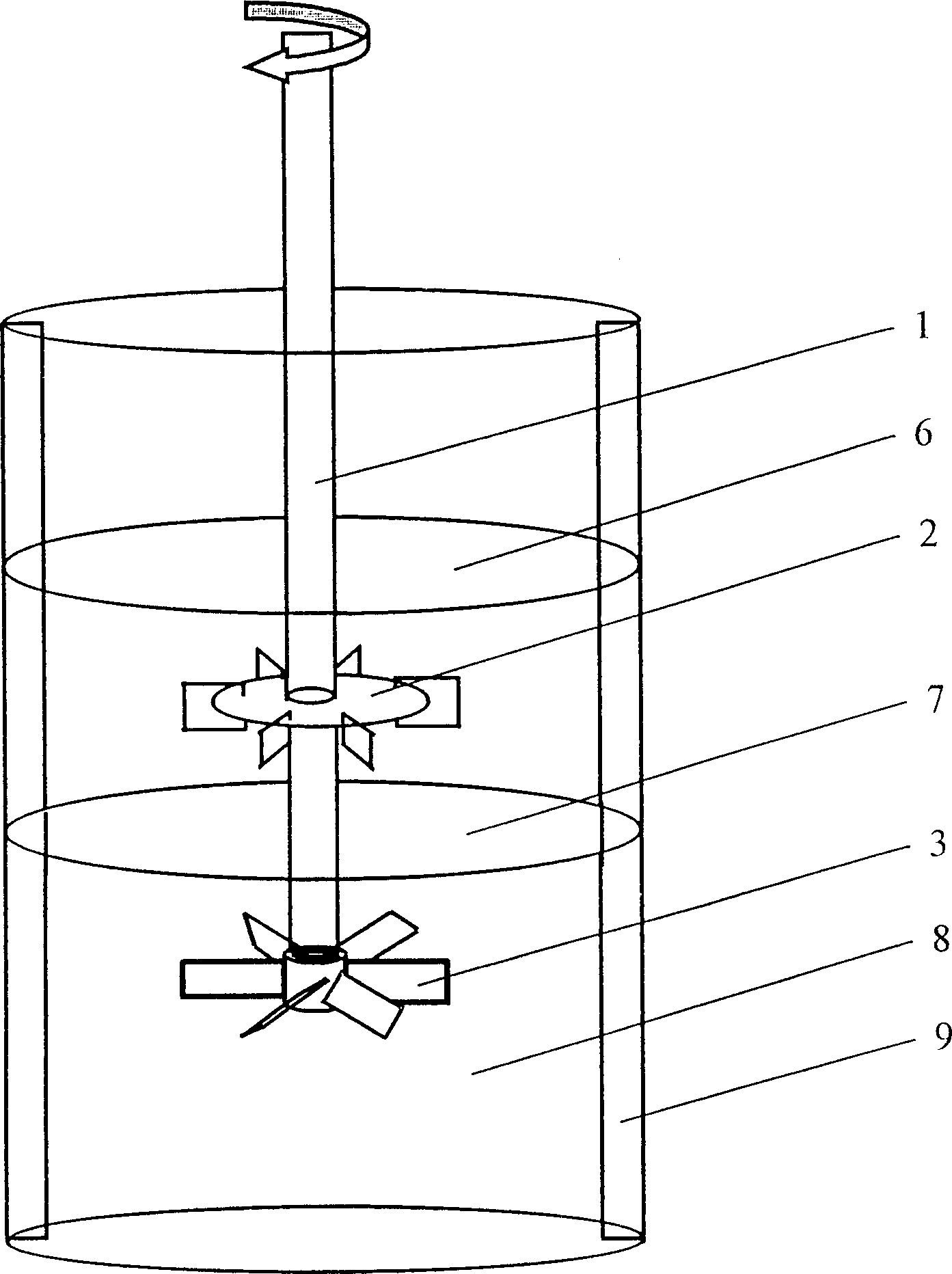

[0016] attached image 3 and 4 It is the structural representation of two embodiments of the present invention; As can be seen from the figure, the surface aeration type multiphase contact stirring device provided by the present invention comprises a stirring tank 8, a stirring shaft 1 installed at the center of the stirring tank 8, and The surface aeration stirring paddle 2 installed at the lower end of the stirring shaft 1 is characterized in that: it further includes an upwardly pushing axial flow paddle 3, and the upward pushing axial flow paddle 3 is installed on the stirring shaft 1 below the surface aeration stirring paddle 2; On the stirring shaft 1 above the surface aeration stirring paddle 2, a spin self-floating baffle plate 4 that freely floats up and down along the stirring shaft 1 and rotates freely is installed; The diameter of the circular baffle is smaller than the inner diameter of the stirring tank 8 and larger than the outer diameter of the surface aeratio...

Embodiment 1

[0021] For the gas-liquid two-phase system, the inner diameter is φ154 mm, the height is 300 mm, and four stirring tank baffles 9 are symmetrically arranged on the inner side of the tank wall. In the cylindrical open stirring tank 8, the medium is water and air, and the liquid level in the tank is high. 240 mm, the width of the baffle plate 9 of the stirring tank is 15 mm; the surface aeration stirring paddle 2 adopts a standard Rushton paddle with a blade diameter of 62 mm, and the push-up axial flow paddle 3 adopts a 45-degree push-up inclined blade turbine paddle, and the paddle The leaf diameter is 58 millimeters, and the spin self-floating baffle 4 is made up of 12 fan-shaped pieces of the same size, and the fan-shaped pieces are twisted to form an angle of 30 degrees with the horizontal plane, and the diameter of the spin-self-floating baffle 4 is 75 millimeters; this embodiment includes Three stirring tank configurations, one is figure 1 The one shown uses a single Rush...

Embodiment 2

[0024] For the gas-liquid-liquid three-phase hydroformylation reaction system of 1-dodecene catalyzed by water-soluble rhodium-phosphine complex, the concentration of 1-dodecene is 4.4×10 3 Mole / cubic meter, the concentration of aqueous phase rhodium-phosphine complex catalyst is 1.0 mol / cubic meter, and the phosphine-rhodium ratio is 18, and the mass percent concentration of adding surfactant CTAB is 0.3%, the volume of organic liquid phase and aqueous phase The ratio is 1 / 1, and the reaction mixture is composed of H with a molar ratio of 53 / 47 2 and CO, the reaction pressure is 1.1 MPa, and the reaction temperature is 90°C. The U-shaped bottom cylindrical reaction kettle 8 with an effective volume of 500 milliliters is adopted, and the total volume of the liquid phase in the kettle is 200 milliliters.

[0025]This embodiment includes three kinds of stirred tank configurations, one is to adopt such as figure 1 The single Rushton paddle 2 shown, the other adopts a double-lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com